Dr Jacques Levrat, Project Coordinator at CSEM, details the journey of the HIPERION solar technology project so far, from production line to pilot sites.

In the 14th edition of The Innovation Platform, we introduced the HIPERION technology, which combines concentration photovoltaics (CPV) and micro-tracking on ultra-high efficiency space-grade solar cells, resulting in a remarkable 40% increase in energy production compared to traditional PV solutions.

Through our global pilot deployment in Chile, Spain, Portugal, Germany, and Switzerland, we are now gaining valuable insights into the performance of HIPERION modules under diverse climatic and lighting conditions. Our analysis of energy generation curves demonstrates the adaptability and efficiency of the modules in various lighting scenarios.

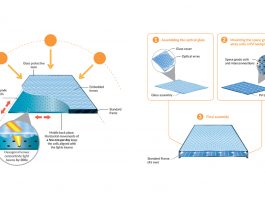

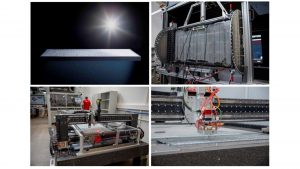

Additionally, we are proud to showcase the establishment of our pilot production line, equipped with cutting-edge machinery that plays a vital role in the manufacturing process. These include a characterisation bench for precise positioning and alignment, a lens assembly tool for front plane production, a frame machine for seamless integration, and a unique hybrid flasher for accurate power assessment.

Record-breaking efficiency and global pilot deployment

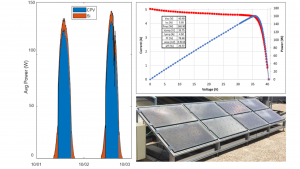

HIPERION solar technology has achieved a groundbreaking milestone with a record-breaking efficiency of 30% under direct light, as demonstrated by the current-voltage (IV) curve (Fig. 2, top right). This remarkable achievement solidifies the superiority of HIPERION modules in the field of solar energy, positioning them at the forefront of cutting-edge solutions.

The integration of optics and a concentration factor of 200x allows HIPERION to effectively harness concentrated sunlight on space-grade solar cells, resulting in higher energy conversion rates and maximum energy output.

Strategic deployment of HIPERION pilot modules across diverse locations worldwide – including the Atacama Desert in Chile, Madrid in Spain, Porto in Portugal, Freiburg in Germany, and Gstaad and Lausanne in Switzerland – enables comprehensive evaluations of the technology’s performance under varying direct and diffuse light conditions. These unique locations provide valuable insights into the adaptability and effectiveness of HIPERION technology modules in maximising energy production across different geographical and climatic settings.

Each pilot site serves a specific purpose in assessing the hybrid modules’ performance. The Atacama Desert offers insights into performance under intense direct sunlight; Madrid represents a Mediterranean climate with a balanced mix of direct and diffuse light; Porto showcases performance in a temperate climate; and Freiburg allows the study of behaviour in changing Central European weather patterns. The pilot sites in Gstaad and Lausanne offer valuable insights into performance in mountainous and urban environments.

Monitoring energy generation curves in these diverse locations validates the real-world effectiveness of HIPERION hybrid technology, demonstrating its adaptability and reliability under different lighting conditions. These findings drive further refinements and advancements in the technology, paving the way for widespread deployment and commercialisation. Fig. 2 (below) showcases the simultaneous production of energy from direct (CPV) and diffuse light (Si) components on a clear sky day in Madrid.

The role of the pilot line

The HIPERION pilot line, a key component of the project’s roadmap towards GW-scale industrialisation, showcases the strong collaboration within the HIPERION consortium. Leading industrial partners, such as Mondragon Assembly, IQE, and 3S Solar Plus, have played instrumental roles in defining the roadmap and bringing the vision to reality. One of the primary goals of the pilot line is to demonstrate the compatibility of HIPERION solar technology with industrialisation.

By showcasing highly innovative architecture and utilising local supplies, the pilot line aims to boost the revitalisation of the PV industry in Europe. The integration of cutting-edge technology and efficient production processes in the pilot line highlights the potential for large-scale deployment of the HIPERION modules.

To date, the pilot line has successfully produced and installed over 100m2 of hybrid panels worldwide. This achievement underscores the scalability and readiness of the HIPERION technology for real-world applications. By demonstrating the viability of the technology on such a scale, the pilot line serves as a catalyst for the widespread adoption of HIPERION modules.

The pilot line’s accomplishments, combined with the expertise and collaboration of the HIPERION consortium industrial partners, pave the way for the future success and growth of the PV industry in Europe. Through continuous innovation and the establishment of strong supply chains, Europe can develop the necessary industrial capabilities at every level to position itself as a global leader in renewable energy.

HIPERION technology is a frontrunner in the quest for a green future

The HIPERION pilot line has yielded groundbreaking results that have propelled the field of hybrid photovoltaic technology to new heights. The achievement of record-breaking efficiency, with an impressive 30% under direct light, showcases the superior performance of HIPERION modules and their capability to maximise energy production.

The global pilot deployment in diverse regions such as Chile, Spain, Portugal, Germany, and Switzerland has provided invaluable insights into the adaptability and effectiveness of the technology under various lighting conditions. The monitoring of energy generation curves in these locations has validated the hybrid technology’s capability to harness both direct and diffuse light, further cementing its reliability and versatility.

The role of the production machinery within the pilot line, including the characterisation bench, lens assembly tool, framing machine, and hybrid flasher, cannot be understated. These machines have played a pivotal role in ensuring the efficient and high-quality production of HIPERION modules. With the unique capability of the characterisation bench to determine component positions with ultrahigh accuracy and the hybrid flasher’s capability to conduct precise power assessments, the pilot line has set a new standard in manufacturing processes.

The results achieved through the HIPERION pilot line have not only advanced the field of hybrid photovoltaic technology but have also set the stage for a revolution in clean energy production. The combination of record-breaking efficiency, global deployment, sustainable energy generation, and state-of-the-art production machinery positions HIPERION solar technology as a frontrunner in the quest for a more sustainable and renewable energy future.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 857775.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 857775.

Please note, this article will also appear in the fifteenth edition of our quarterly publication.