Digital watermarking is stepping into the spotlight as a powerful solution for tackling one of recycling’s biggest challenges: accurate sorting of plastic packaging.

The latest results from the Digital Watermarks Initiative HolyGrail 2.0 trials, led by AIM and powered by the Alliance to End Plastic Waste, mark a major leap forward in proving the technology’s potential at an industrial scale.

Held at the Hündgen Entsorgung material recovery facility (MRF) in Swisttal, Germany — which processes 100,000 tonnes of waste per year from over three million households — the pilot tested rigid plastic packaging embedded with digital watermarks. These marks allow packaging to be identified with far greater accuracy than traditional sorting systems.

This development signals a turning point toward a truly circular plastics economy, with smarter sorting, improved traceability, and packaging-level precision now within reach.

5.66 million detections over 100 days

Running from 19 August to 19 December 2024, the trials put Digimarc’s digital watermarking system to the test.

The facility was equipped with hybrid detection modules co-developed by Digimarc and Pellenc ST, combining near-infrared (NIR) technology with digital watermark recognition.

Across 100 days, the system recorded:

- 5.66 million detections

- 5,949 unique SKUs

- An average of 56,000 detections per day

- Detection accuracy ranging from 87.9% to 93.8%

These results were achieved in a single-pass sorting environment, making them even more impressive given the challenges of dirty, overlapping, or irregularly shaped packaging often found in post-consumer waste streams.

Diverse packaging, high accuracy

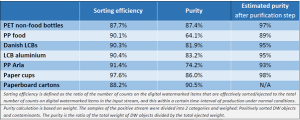

The trials covered four key packaging types: PET non-food bottles, PET trays, rigid polyethylene (PE, including tubes), and rigid polypropylene (PP).

Participating brands included major FMCG players such as Procter & Gamble, Aldi, Mondelēz International, Orkla, and Arla Foods, all of whom placed digitally watermarked products in the German and Danish markets for real-world collection and recycling.

To strengthen the test stream, additional digitally tagged packaging – such as Coca-Cola and McDonald’s beverage cups and tobacco canisters from Imperial Brands – were added.

The system’s ability to consistently identify and sort this diverse mix of materials underscores its commercial readiness.

Unlocking SKU-level sorting and traceability

One of the most transformative aspects of digital watermarking is its potential to enable SKU-level sorting – a level of detail unachievable with traditional recycling technology.

This granular sorting opens the door to smarter waste traceability, data-driven recycling practices, and compliance with upcoming regulatory demands, including the EU’s Packaging and Packaging Waste Regulation (PPWR).

From January 2030, new requirements will demand increased recycled content in plastic packaging. Digital watermarking could play a pivotal role in meeting those targets by delivering cleaner, more precisely sorted recyclates.

Next Phase: HolyGrail 2030 and market rollout

With HolyGrail 2.0 concluding successfully, the initiative now transitions to the next stage: HolyGrail 2030 – Circular Packaging.

This phase will focus on proving the economic viability of smart sorting solutions and expanding access to high-quality recycled materials for reuse — including in food-grade applications.

Early market demonstrations are planned in Belgium (for flexible PP food packaging) and Germany (for rigid PP food packaging), paving the way for broader adoption and circular innovation across the packaging value chain.

A turning point for recycling

The HolyGrail 2.0 trials show that digital watermarking is not just a promising concept — it’s a viable, scalable technology ready to transform recycling as we know it.

With consistent detection rates above 90% and millions of successful identifications under tough conditions, the future of circular packaging just got a lot closer.