Mike Campigotto, President of SafeSight Exploration, introduces its portfolio of remote inspection and monitoring solutions that can improve efficiency and safety in mining.

Technology has now turned its attention to making deep impacts on the mining industry. In-motion laser technology, high-definition (HD) video, thermal imaging, and gas sensing technology has become small enough and sophisticated enough to improve safety in mining and protect those who work deep underground.

SafeSight Exploration Inc is a high-tech organisation dedicated to applied technology in the mining sector. The company’s mission is to provide cutting-edge remote inspection and monitoring solutions that help organisations improve safety, reduce downtime, increase operational efficiency, and optimise asset management in mining.

While our initial development and deployment was our underground mapping drone, we quickly learnt that we had the capability and passion to reimagine mining operations underground. We have become an organisation focused on innovation that is relentless in the pursuit of transformative solutions.

SafeSight has differentiated itself from other technology suppliers in several ways.

We have taken the time to walk in the boots of our customers. By embedding our designers, engineers, and product developers underground, we have developed greater insight to innovation opportunities.

We have learnt that solutions must be flexible and adapt to the immediate need. That understanding has led us to ensure our solutions are interoperable and adaptable because, much like outer space, inner space often does not want to co-operate.

Most importantly, we have recognised that the need for deep customer collaboration, shared risk, and continuous improvement is the path to real paradigm change in the future of mining.

SafeSight has earned the attention and collaboration of some of the industry’s leading mining organisations, such as Redpath, Vale, Newmont, amongst others.

The result has been the creation and deployment of innovation that has impacted fundamental components of the mining value chain, specifically:

- Underground mine rescue;

- Shaft measurement and management;

- Underground mapping using Light Detection and Ranging (LiDAR) technologies; and

- Vertical mining using mechanised raise climbers.

The safety and efficiency impacts of these solutions are no less dramatic than the innovations themselves.

Workers are ultimately safer. Technology takes the risk of the operator. By removing the worker from harm’s way, we remove the potential for serious injury.

Productivity improves not only at the point the innovation is introduced, but it compounds along the value chain until it ultimately affects tonnes per day and grams per tonne.

We recognise that these innovations have the adaptability to go ‘beyond mining’ to influence the digital future of other industries, including oil and gas, power generation, and construction.

Underground mine rescue

Technology can now extend the reach and range of underground response to rescue and emergency.

Responders are safer, can operate underground for longer periods of time, and can more rapidly identify the situational details that dictate whether a rescue or recovery is required.

Safesight has created a new set of tools for mine rescue and underground emergency response that applies this technology to create an adaptable toolkit that allows responders to meet the needs of an ever-changing situational dynamic.

After working with and consulting with experts in the field, we created a suite of innovative solutions that can adapt to an evolving emergency in the future of mining.

Our tools provide remote HD video, thermal vision, and gas levels that can be delivered in whatever format the situation demands.

The HD video can be used in tight spaces or areas where it is unsafe for responders to enter, such as collapsed areas or where ground conditions will not allow responders access.

The thermal vision can ensure sight when smoke or dust are creating zero visibility from a fire, blackout, or fall of ground.

The gas sensor technology can reach almost anywhere beyond the responder operating point to quickly determine breathing conditions and potentially conserve precious oxygen supplies.

Remote fire response can confirm fire status or remotely deploy a fire hose and water supressing curtains to help responders safely battle active fires underground.

Our plug-and-play design offers the capability to quickly create the right response mechanism in what can be a rapidly-changing scenario.

HD, thermal and gas sensor technology can go from a drone to any other available piece of equipment. In under two minutes, ground-based response can be converted to a HD, thermal and gas sensing utility vehicle.

This level of flexibility ensures that critical rescue data to make effective response decisions can be gathered in almost every possible scenario. In each of these scenarios, responders are kept out of harm’s way and, where human risk is required, it is done with the maximum amount of data intelligence to mitigate the risk.

It is not difficult to see the application of these same capabilities in fire and policing, pipe inspection, structural assessment, and search and rescue in collapsed structures.

Shaft measurement and vertical mining

Why send people into shafts and unknown underground cavities when the technology exists to take their place? Underground technology for the future of mining now makes shaft management safer, more accurate, and eliminates outages created by reactive maintenance.

Types of underground operational arteries that have a dramatic impact on a mine site’s productivity and performance include the shaft – the principle mover of workers and material – and passes – which are the laundry shoots that move precious metals from one level to another and ultimately to their destination in crushers and mills.

When these arteries are obstructed, materials stop moving and the value chain underground comes to a standstill. By taking extended periods to measure, manage, and maintain them, you slow down the operational value chain and affect a primary metric for any operational site tonnage per day.

Shaft measurement and management can be transformed. SafeSight has developed a set of tools and processes for the future of mining. They automate the shaft measurement process to create a new digital asset or digital twin of the shaft and all its compartments to 1mm of accuracy. This can be done well, removing workers from traditional high risk in shaft measurement activities and, in some situations, eliminating live work for remote data gathering.

Traditional exercises, such as guide alignment which can take extensive manpower and effort, can now be repaired and replaced with digital guide alignment. This can be done in hours as opposed to days and captured in a way to support regression measurement overtime.

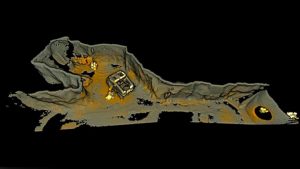

Mechanised rail climber development

Mechanised rail climber (MRC) development is often used to develop and manage critical passes that can be used to move materials or create needed ventilation. Although extremely agile and cost effective, this approach had its safety challenges.

SafeSight’s MRC rail runner was developed to remove the inherent risks from MRC development. This autonomous rail climber can not only assess the development with high-definition video but can simultaneously assess gas conditions in the raise and create a 3D model of the raise, removing the need to put survey teams at risk in measuring an area of unsecured ground.

This technology expedites the development process by achieving multiple outcomes at the same time, including:

- Highlighting any installation drilling or structural issues;

- Identifying any peak gas levels; and

- Ensuring that the orientation of the rays and the rail align with the development plan.

More importantly, all of these outcomes are achieved while keeping workers and supervisors out of the development area until it is confirmed that it is safe and secure to enter.

This is lifesaving technology that removes workers from harm’s way, while at the same time creating a more productive development cycle that can demonstrate compliance. It is not hard to understand why governments are moving to revise health and safety regulations for the future of mining.

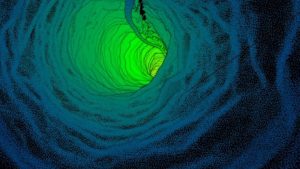

Underground mapping for safety in mining

3D mapping capability underground can now be completed three times faster than traditional methods. In-motion LiDAR mapping is cheaper, faster, and safer than any traditional 3D modelling solution today. Its flexibility allows it to capture data by air, ground, cable and as a handheld unit. For the future of mining, this means better decision-making data for planners and engineers as they look to maximise production potential.

SafeSight’s SafeScanner is a lightweight, in-motion scanner that can collect data in several configurations to meet the needs of the moment, all while keeping operators far from harm’s way. Operators can use underground drones, remote ground units, and handheld carry or cabled configurations to collect any data anywhere.

Impacts and implications are realised immediately and range from productivity to profitability.

LiDAR mapping of 3D models takes about 25% of the time of traditional mapping when using traditional modelling technology.

The ability for our technology to reach deeply into the target area means 100% of the area is digitally captured, compared to about 70% using traditional methods.

Post-data collection processing on a surface is not required or can be reduced from hours to minutes.

In summary, faster and more accurate decision data can be captured while keeping workers out of harm’s way.

The ripple in the value chain is significant. 3D modelling data is used in the post-blast reconciliation process to determine if the target has been fully harvested of its precious metals. Taking too much material can dilute the quality of the ore, but taking too little could mean that valuable materials get left behind.

Our LiDAR solutions ensure accurate data for optimal extraction goes directly to the grams of ore per tonne of materials excavated, which translate to the site’s bottom line.

Technology and technologists have come of age and are turning their attention to underground applications to not only make a deep impact on how things are done in the mining sector but to create a seismic shift in levels of worker safety. The only real challenge left in the future of mining is acceptance and adoption by the industry itself.

Please note, this article will also appear in the fourteenth edition of our quarterly publication.