Pierre Forêt, Associate Director of Additive Manufacturing at Linde, explains how materials science is revolutionising the manufacturing sector.

An indispensable cross-industry discipline for advancing product design and manufacturing, materials science is a field defined by innovation and creative thinking.

It focuses on how materials behave at every level, including how microstructures and the arrangement of individual atoms and molecules can significantly influence a material’s behaviour – and how a structure can be manipulated to influence desired performance.

Lying at the intersection between engineering, physics, and chemistry, materials science is a foremost consideration in developing new products, often resulting in sophisticated and unique properties.

Materials science digs deep into the relationships between physical and chemical knowledge and how different materials – everything from metals and polymers to composites and nanomaterials – can be engineered to achieve better performance.

This can include commercially beneficial advantages such as more efficient production processes, extending the life of a part and reduced maintenance to more fundamental societal benefits such as improved healthcare outcomes and greater energy and environmental sustainability to enable sports excellence and aerospace technology.

Influencing a material’s microstructure can lead to some remarkable behaviours – including a material’s flexibility – so how far the material can be stretched or bent.

It can also impact the hardness of a material, making it more corrosion resistant or on its ability to conduct electricity or heat.

A perfect example, which we’ll discuss later, is shape memory alloys – or metals that can be bent and returned to their original shape by applying heat.

Materials science advancing new manufacturing techniques

Once thought destined mainly for prototyping, additive manufacturing is increasingly employed in developing spare parts, small series production and tooling in forward-thinking manufacturing industries such as aerospace, electronics, automotive and medical devices.

Among industries at the forefront of innovative manufacturing, the medical sector has emerged as a major segment driving the growth of additive manufacturing.

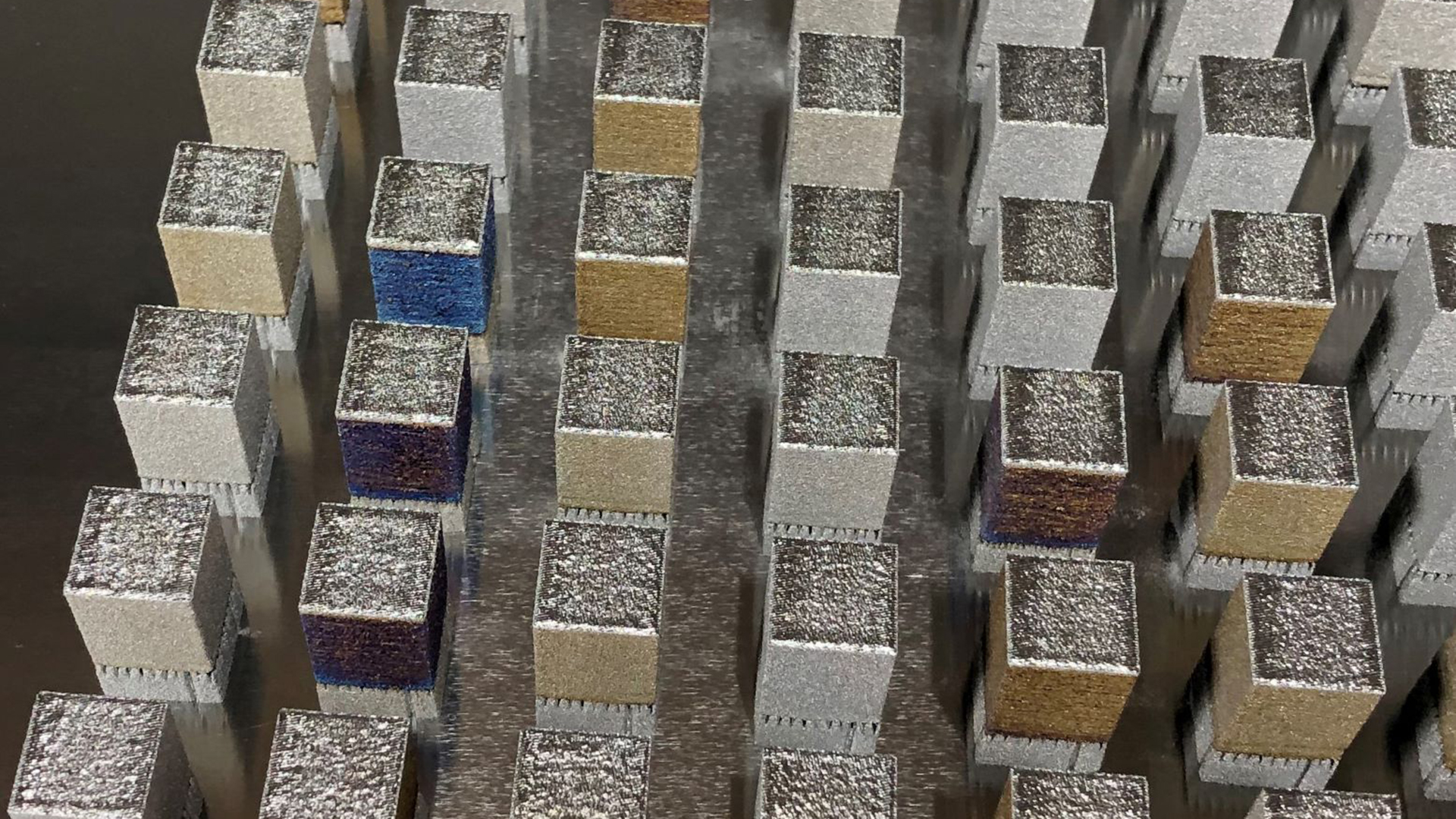

By fusing metal powders layer by layer, using several different sintering or laser-based techniques, additive manufacturing can build complex components that would typically be very challenging – if not impossible – with more traditional subtractive manufacturing methods.

The advantages of additive manufacturing include greater design freedom and customisation, improved product strength and functionality, reduced assembly time for complex components, localised production, rapid time to market, mitigation of wastage, reduced obsolescence, decreased reliance on traditional suppliers and even the creation of new materials with unique mechanical and behavioural properties.

Most additive manufactured parts are made from alloys – both conventional and novel. However, very few alloy parts are produced this way that have the same quality or retain the same mechanical properties offered by similar alloys when manufactured via a conventional process such as forging.

Their behaviour does not respond similarly, largely due to the rapid melting and solidification they undergo in the additive manufacturing process.

As the additive manufacturing industry has faced a challenge in retaining or even improving the characteristics of metal alloys, it has looked to materials science and engineering to enable the development of alloy parts with superior mechanical properties.

A case in point

Discovered over 50 years ago, nitinol (NiTi) is an especially valuable metal alloy that has revolutionised numerous industries.

Made of 50% atomic nickel and 50% atomic titanium, it has unique properties, allowing for its superelasticity and “shape memory effect”, meaning it can change shape depending on temperature. This special behaviour now sees nitinol increasingly used in the medical, dental and aerospace industries.

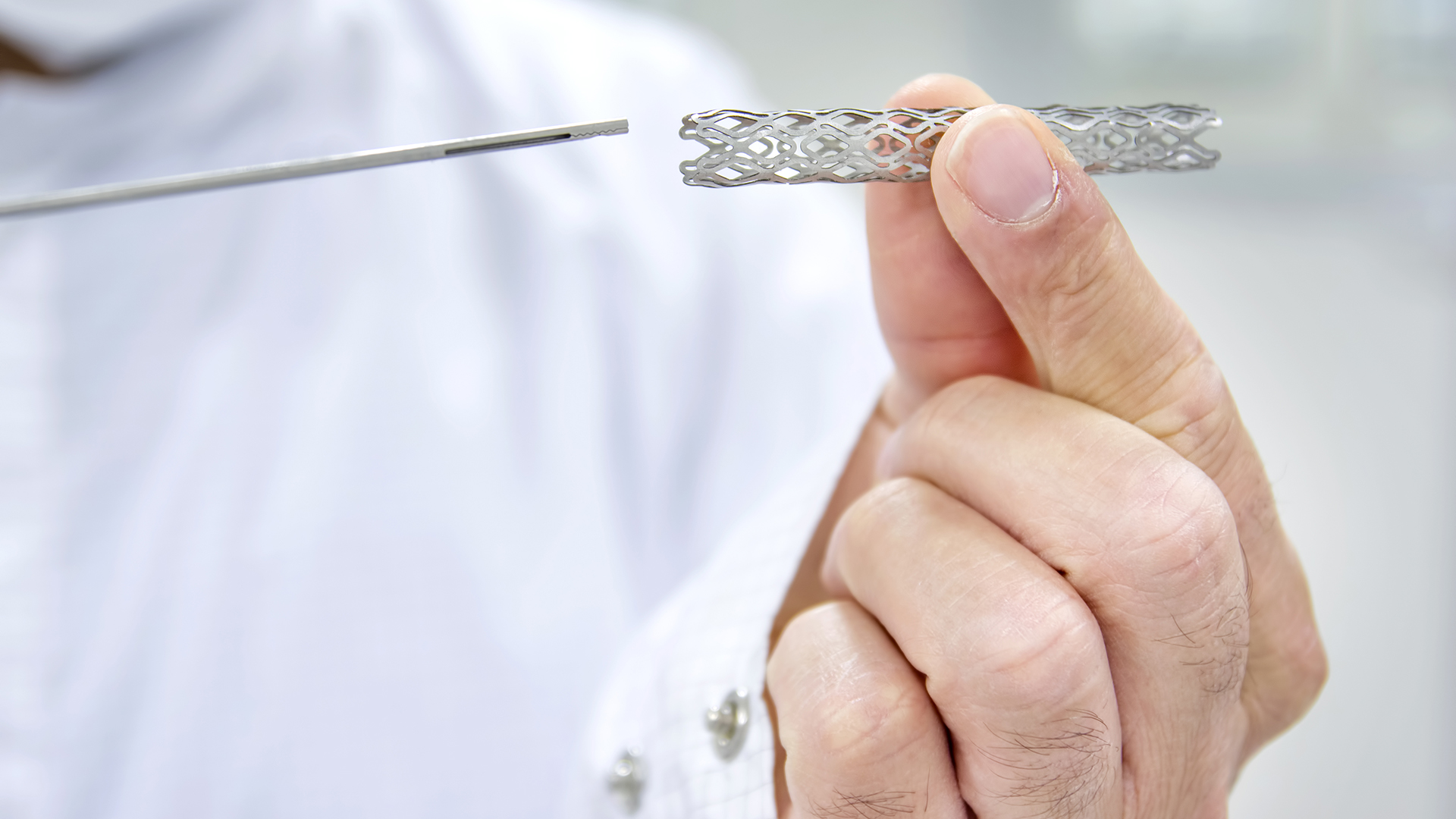

Nitinol is an excellent material for creating components for minimally invasive medical devices, such as guidewires, catheters, and stents. When medical professionals need to navigate in particularly tight areas, nitinol has both the flexibility to change shape as needed and the durability to endure high amounts of strain.

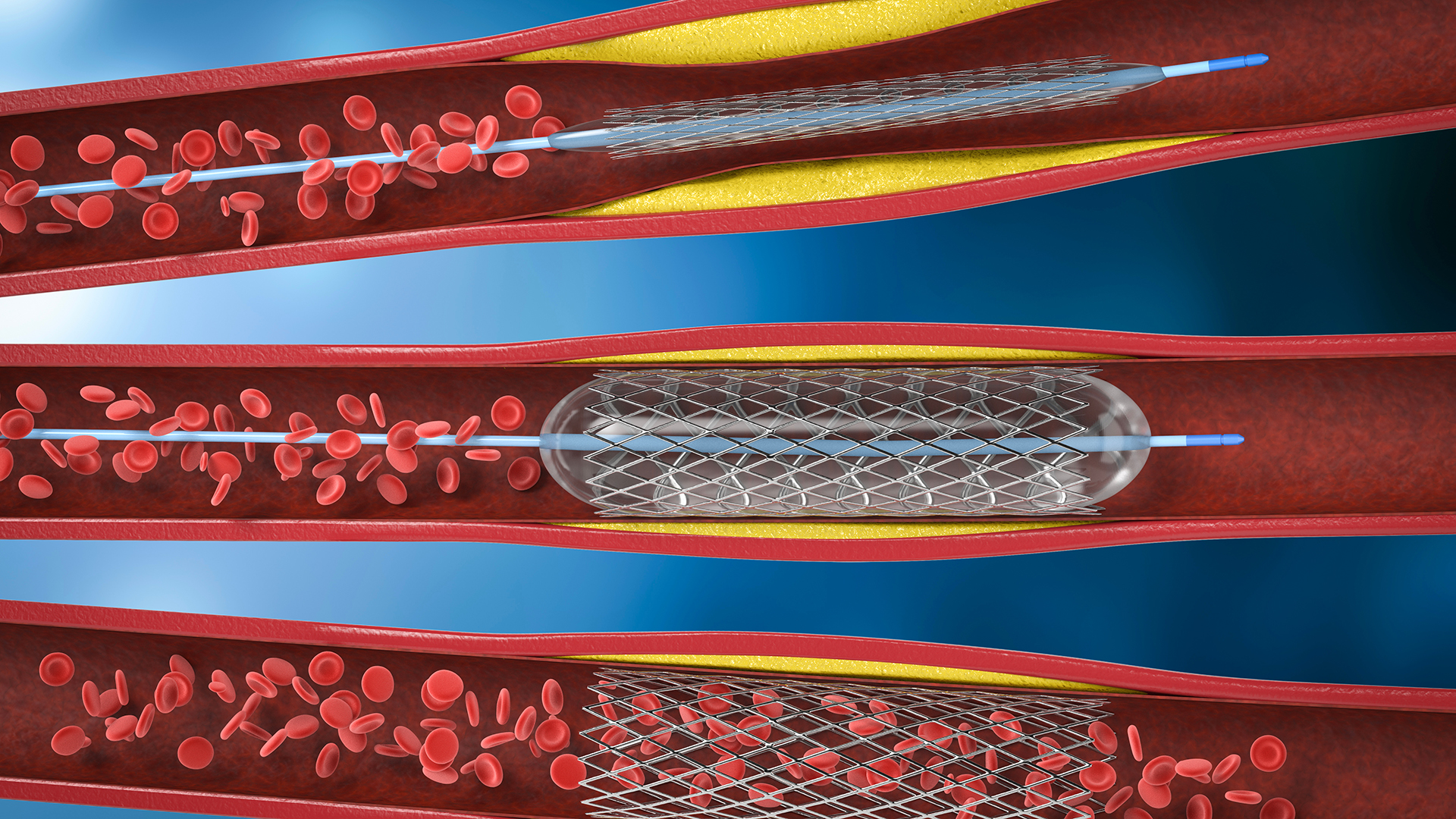

Stents used to keep arteries open are perhaps the clearest example of why nitinol’s superelasticity and shape memory effect is so beneficial. When stents are inserted into the body, they can be compressed down to a tiny size to be used in minimally invasive procedures.

When they are placed at the right point in the artery, however, they expand to fill the necessary space and brace the inside arterial wall, a procedure that could not be done using stainless steel.

In orthopaedic procedures, surgeons need components that will help patients regain flexibility and range of motion and easily adapt to an individual patient’s tissue. Nitinol is the preferred material for these components, as it mimics bone mechanical behaviour.

Orthodontists also need wires and brackets that hold braces together and perform the function of moving teeth, so nitinol’s shape memory is particularly useful in the printing of nitinol applications.

Materials science overcomes production challenges

Despite all its advantages, developing components made from nitinol can have its challenges. The alloy can be difficult to machine, so product design has typically been limited to simple structures.

Such difficulties include high toughness, high ductility and work hardening in cutting processes. So traditional machining results in excessive tool wear, high cutting forces and surface degradation, often ending in low workpiece quality with inferior chip breaking and burrs formation.

And while additive manufacturing can offer improved production efficiency and greater design freedom, there are still issues to be overcome when printing with nitinol.

The vaporisation of the nickel during the additive manufacturing process can decrease the nickel/titanium ratio, thereby increasing the transformation temperature. Additionally, oxygen pick-up inside the material can also affect the transformation temperature, negatively impacting shape memory and affecting the overall performance of the intended application.

It is here where a deep knowledge of materials science has led engineers to understand the impact of the printing chamber’s atmosphere on the printed part and why the atmospheric conditions need to be optimal.

Although the atmosphere in the chamber is purged with high-purity argon to rid it of oxygen, impurities remain present due to incomplete purging and small leakages.

Even extremely small variations in oxygen content can impair the mechanical or chemical properties of metals and alloys sensitive to oxygen – including nitinol – and can affect the composition of the end product resulting in negative physical characteristics such as discolouration and even poor fatigue resistance. Typically, after purging, the level of residual oxygen is around 1,000ppm – far off the ideal of less than 10ppm.

The materials scientists and engineers at Linde have dedicated the past few years to developing pioneering technology to overcome these atmospheric impurities to give manufacturers optimal printing conditions.

The result – ADDvance® O2 precision – provides continuous analysis of the gas atmosphere, detecting oxygen levels with high precision without cross-sensitivity. Recognising O2 concentrations as low as ten parts per million (ppm), the unit automatically initiates a purging process to maintain the atmosphere as pure as needed.

For the printing of nitinol components, it is critical to maintain both a low and constant O2 level. If this is not achieved, the material can oxidise – either from too high an O2 level or the mechanical properties varying from one part to the next.

Materials science expertise has also led to developing unique and bespoke gas mixtures, such as ADDvance Laser230, developed specifically to optimise printing outcomes. Successfully tested on a range of alloys, including high-strength aluminium AISi10MG, nickel-based superalloys, titanium, nitinol and stainless steel, it combines argon with helium to reduce particle redeposition by up to 30% and powder loss by up to 20%.

It also saves on maintenance time, with fewer changes of filters required. In addition, it mitigates fume formation and accelerates printing times, making the printing process safer and lowering the cost per part. It is alloy agnostic and ideal for additive manufacturing of lattice structures.

With such advancements in additive manufacturing technologies, nitinol will not only enable the future of medical procedures to become less invasive, but it will also open up possibilities to manufacture leading-edge products and components that have previously been out of reach.

The future outlook for the sector

While materials science has been around at varying levels of sophistication for generations, it may now be the most important discipline for our future. For most major challenges we face, materials in one form or another are likely to be at the heart of the solution.

From building a clean energy future to enabling previously inconceivable life-extending surgeries, materials science is propelling manufacturing innovation forward.