Experts from Norsk Elektro Optikk AS (NEO) explain how HySpex hyperspectral cameras in mining can offer innovative ways to explore and monitor mines efficiently and sustainably.

Hyperspectral imaging (HSI) offers the mining industry an innovative solution that can drive business value, sustainability, and operational efficiency. While the technology is mostly adopted in mineral exploration via the use of hyperspectral core scanners, high-quality camera systems offer many benefits within operational mining and post-mining landscapes. HSI can provide detailed information on the composition and distribution of minerals and other materials within a geological context. The technology facilitates rock and mineral mapping and characterisation, can resolve surface patterns indicative of subsurface activity and map environmental changes such as vegetation health and changes in surface pH.

Using different HSI tools along the life of mine and mining value chain enables mining companies to identify and evaluate extracted materials as well as geospatially monitoring the areas in their care, adding to existing point-based information from drilling or sampling. Benefits include product quality control, grading, close-to-face sorting, tailings monitoring, waste processing and rehabilitation. It ensures that mining activities adhere to regulatory standards and produce consistent, high-quality outputs.

Usage of HSI promises to reduce operational costs by providing faster results than traditional methods and by ensuring consistent ore grading and mine planning. Besides primary raw materials, HSI already plays a critical role in the secondary raw materials sector as the technology supports recycling and repurposing of mining by-products and consumer end products. Here, we present how HySpex hyperspectral cameras are becoming a vital tool for mining operations seeking to balance profitability with ecological stewardship, and give examples of successful HSI utilisation along the mining value chain.

Principles of imaging spectroscopy

Hyperspectral imaging, also known as imaging spectroscopy, combines two techniques: digital imaging and light spectroscopy. In addition to the spatial information, a hyperspectral pixel contains a continuous spectrum with hundreds of different wavelengths (or bands). An image generated in this way provides spectroscopic information for each pixel of the scene, which can be used to identify, classify or quantify the materials in the scene according to their spectral ‘signature’.

In mining applications, hyperspectral cameras can be mounted on heavy-duty tripods, uncrewed aircrafts and aeroplanes, over conveyor belts and other conveying platforms, in mobile laboratories, over truck-loading or weighing stations and in many other locations. The cameras are versatile, flexible and robust. They only need to be in the line-of-sight of the object and with solar or artificial illumination active in the visible to near-infrared (VNIR; 400-1,000nm) to shortwave infrared (SWIR; 1,000-2,500nm) to capture reflected information from the surface. The spatial imaging context of the data allows geologists to get a bigger picture of the data, literally, reducing potential inconsistencies stemming from sampling errors for other geochemical and mineralogical methods.

With HSI cameras operating in the VNIR and SWIR wavelength ranges, rock material from all stages of the mining value chain can be investigated by studying the characteristic absorption features, inflections, and signature slopes of the individual (pixel) spectrum captured by the imaging system. In geological environments, absorption features detected in the VNIR arise from transitional elements, including iron-bearing minerals and rare earth elements (REEs), while the SWIR region is commonly used for identifying alteration mineral assemblages related to hydrothermal systems of base and precious metal deposits. The mineral groups that can be detected and mapped in the VNIR-SWIR wavelength regions include carbonates, sulphates, sulfosalts, clays, and phyllosilicates such as chlorite, talc, and muscovite.

New heights in hyperspectral core scanning

The HSI technology, firmly established in core scanning technology, has provided valuable lessons for high-resolution mineral mapping. Hyperspectral core scanning is a non-destructive and time-efficient solution to characterise the alteration footprints of ore deposits. Selected for providing unrivalled datasets with high spectral quality, fidelity, and precision, HySpex Classic VNIR-1800 and SWIR-640 cameras are now also being integrated with Midwave infrared (MWIR; 2,600- 5,500nm) and Longwave infrared (LWIR; 5,500-12,500nm) cameras, yielding data cubes with a combined spectral range of 400-12,500nm. A 3D profiler for surface modelling allows for precise spatial co-registration between all sensors on the core scanner platform. The core scanning platform is optimised to handle high throughput of single to multi-row cores in plastic, cardboard, or wooden boxes, and can also handle drill chip boxes, loose samples, and rock mass. The HSI will generate high-resolution RGB sample images, high-density mineralogic spectral data cubes, and 3D laser profile datasets.

The Breeze Geo software developed by NEO and Prediktera allows for efficient data acquisition, logging, and analysis. Mineralogic output is based on an expert system from the U.S. Geological Survey, but Breeze Geo affords users the additional ability to adjust and adapt with new incoming knowledge from geochemistry, for example, and can evaluate in real-time if and where sampling for validation and interpretation purposes is advised. The resulting mineralogic interpretation and logs can be exported in common formats to be included in other modelling software such as IoGas, Imago, or Leapfrog, which makes it easy to integrate into existing workflows.

HySpex cameras are incorporated into numerous core scanning systems supplied by various service providers globally, producing valuable digital records of core and chips for mineral exploration.

In a 2021 article, BHP announced a significant breakthrough in extending the lifespan of an iron ore mine with hyperspectral technology, implemented by one of NEO’s original equipment manufacturer (OEM) customers. While it is clear that hyperspectral technology can enhance mining efficiency and promote more sustainable production, the ability to extend the operational life of a mine marks a major advancement, solidifying the technology’s role in the mining industry. The article mentions that BHP’s iron ore team developed algorithms to analyse hyperspectral images, identifying the areas of Yandi’s geology that could be most effectively processed to separate saleable iron ore from waste material.

Open-pit scanning and mine modelling

Hyperspectral imaging aids in directing exploration efforts to zones of metal mineralisation, avoiding costly drilling campaigns in unmineralised zones. Minerals like muscovite, illite, and sericite represent common hydrothermal alteration products found in mineralised zones of copper-gold ore deposits.

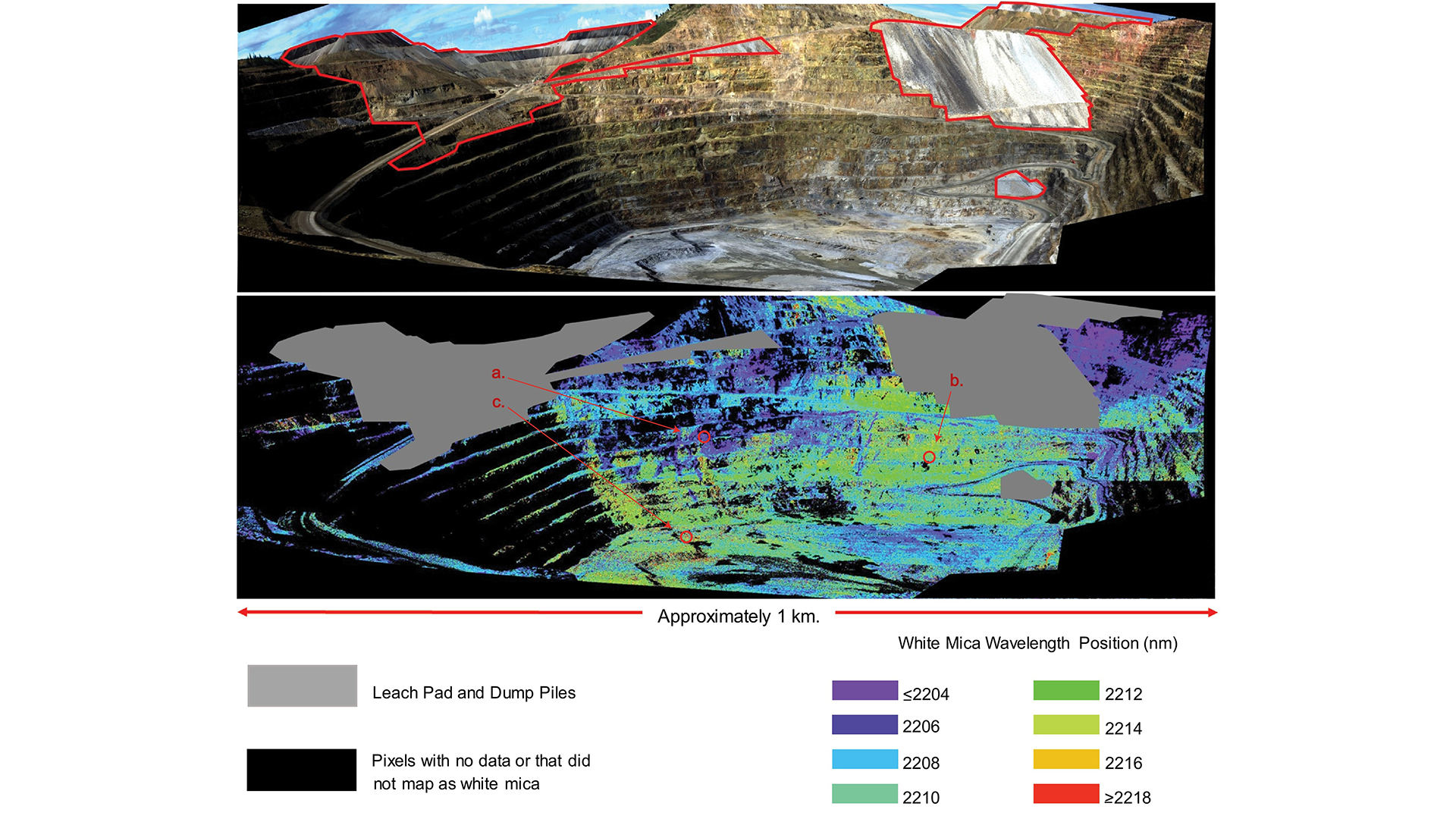

For example, a distinctive spectral absorption feature of these materials can be mapped to show its spatial distribution over an area of interest. Since its exact position is influenced by the mineral’s chemical composition, it can reveal details about alteration type, intensity and fluid geochemistry. More importantly, it can also be an indicator for metal grade. In a study by Meyer et al.,1 this property was mapped at the Cripple Creek and Victor Gold Mine (Colorado, USA) with data collected by the U.S. Geological Survey using HySpex VNIR-1800 and SWIR-384 cameras mounted on a tripod. The results in the image below show a shift of the absorption feature towards longer wavelengths at greater depths. This trend reflects a decrease in aluminium content and proximity to mineralising intrusions.

Conveyor and truck load scanning for quarrying product control

Traditionally, mining operations rely on manual sampling and testing, which is labour-intensive, time-consuming, and prone to human error. Hyperspectral imaging offers a proven alternative by providing fast, comprehensive data on the chemical composition and physical properties of mined materials. This enables mining engineers to analyse small shifts in spectral patterns ultimately identifying mineralogy, or substitution of elements, and to pick up on quality parameters, e.g. indicating changing magnesium or silica content. Moreover, information derived from hyperspectral imaging can be seamlessly integrated into the existing framework, ensuring that the extraction and transport of material are based on precise geological assumptions.

By integrating hyperspectral imaging, mining operators can identify high-quality zones, optimise blasting patterns, and minimise material transported adjustments – ultimately maximising profitability and decreasing the needed resources to achieve a high-quality product. In practical terms, hyperspectral cameras can be strategically deployed at various points along the mining process, including on trucks, mine faces, conveyors, or as mobile labs near drillers. For instance, as trucks haul freshly blasted rock from the quarry face to the crushers, hyperspectral cameras mounted above off-loading facilities can rapidly assess the surface mineral content of the truckload in real-time. This allows operators to identify any deviations from the desired quality specifications and take corrective action as needed, enabling a proactive approach to quality control. By intervening promptly to address such issues, mining companies can minimise product rejections, optimise resource utilisation, and enhance customer satisfaction.

Drone-based scanning and European innovation Drones have rapidly integrated into mine site operations, transitioning from novel tools to essential equipment for stockpile surveys, equipment inspections, and tailings inspections. Traditionally, photogrammetry has dominated drone sensing, creating 3D models of mining sites. However, the landscape is shifting with the advent of various sensors and geophysical instruments, where HySpex hyperspectral cameras are making a significant impact.

Hyperspectral cameras, while not new, have traditionally been deployed on aircrafts, tripods, satellites, and conveyor belts. NEO revolutionised this technology in 2012 by introducing short-wave hyperspectral cameras for drones, addressing the challenges posed by weight and mobility. The ability to collect high-resolution VNIR-SWIR data opens new avenues in mineral mapping, particularly in identifying crucial minerals such as carbonates, sulphates, sulfosalts, clays, various iron oxides, and phyllosilicates like chlorite, talc, and muscovite. These minerals are pivotal in exploration and offer immense value to adjust geometallurgy and mineral processing. Hyperspectral cameras on drones enable early warning systems, tracking ore and waste from bench-to-mill, and monitoring water chemistry and plant health in rehabilitation areas. They have already demonstrated utility in creating automatic geological maps of open pits, inaccessible to geologists.

Drones equipped with hyperspectral cameras offer unique advantages. Flying at lower altitudes, they collect high-resolution data below cloud cover, achieving sub-centimetre resolution when needed. Their capability for repeated surveys enables change detection across various scenarios, facilitating semi-automatic geological and resource model updates, daily flights of production benches, and monitoring infrastructure integrity over significant investments like processing plants. Despite these advancements, widespread adoption in the mining industry remains limited. This hesitance is often attributed to the industry’s perceived conservatism, but the real challenge lies in the complexity of the technology. Compliance with aviation regulations adds another layer of difficulty, requiring extensive training and commitment from already stretched mining professionals.

NEO, alongside European and Australian partners, is addressing these challenges through the M4Mining2 project. This three-year initiative aims to deliver a turnkey drone hyperspectral system capable of returning calibrated, corrected, and interpreted data within 24 hours, targeting a goal of just four hours. The project combines hyperspectral imaging with Light Detection and Ranging (LiDAR), machine vision cameras, and multi-angle gimbals, supported by sophisticated onboard processing software.

M4Mining’s objectives include developing cost-effective methods for regular mapping, monitoring, and geo-hazard prediction. Case studies across Australia and Europe already showcase the system’s capabilities in discovery, operational, closure, and post-closure environments. HySpex’s UAV system offers high spectral and spatial resolution, flexibility, and multi-modal integration. It achieves exceptional spectral resolution with ground sampling distances around between 5-15cm. UAV mobility allows access to remote areas anytime, overcoming the limitations of satellite overpasses and cloud cover. Environmental factors like temperature extremes, humidity, dust, vibration, and shock influence the suitability of HSI cameras. Robust systems such as the HySpex cameras, with high ‘mean time between failure’ ratings, environmental sealing, and protective measures ensure reliable performance. Operational efficiency is enhanced by systems with easily sourced spare parts, minimal cables, and extended battery life.

The M4Mining project, backed by NEO, invites industry participation, offering early insights into the transformative potential of drone hyperspectral imaging. By integrating cutting-edge technology with practical mining applications, NEO is poised to lead the industry into a new era of precision and efficiency.

Making the best with state-of-the-art research and industry-ready solutions

Norsk Elektro Optikk AS (NEO) is developing specialised solutions within EU-funded projects, for example to develop a sorting system for refractory bricks, integrated with laser induced breakdown spectroscopy and developing drone-borne solutions for tailings and mine face monitoring. NEO also participates in several satellite projects that will aid in exploration efforts for green technology metals, for instance the development of an instrument for microsatellites, the HYPERNOR project (ESA GSTP) will add an important space instrument with 9m ground sampling distance from 500km altitude.

NEO is a member of the research consortium CASERM, the Center to Advance the Science of Exploration to Reclamation in Mining. Together with the Colorado School of Mines and Virginia Tech, hyperspectral technology and software is integrated into mining workflows and the consortium provides active interactions and developments with feedback from major mining companies on the handling and usability of both the software and the hardware. Making systems that are accessible, allowing for non-expert user interaction and providing guidance to further a client’s goals, is integral to the development of HySpex cameras and solutions at NEO.

NEO, through the brand HySpex, is recognised as a leading original equipment manufacturer (OEM) of hyperspectral systems for many key service providers in the mining industry. While the use of this technology is still in its early stages, it is expected to become increasingly common in the coming years. NEO provides camera modules or fully-integrated hyperspectral solutions that come with real-time processing software. For those who prefer to manage the software independently, a platform-independent Software Development Kit (SDK) is provided to support development needs.

NEO is continuing to innovate, collaborate and offer new solutions within the fields of hyperspectral imaging for use in mining operations. If you’re looking to increase efficiency and lower costs for your mining operation, please contact us for more information.

References

- John M. Meyer, Raymond F. Kokaly, Elizabeth Holley, ‘Hyperspectral remote sensing of white mica: A review of imaging and point-based spectrometer studies for mineral resources, with spectrometer design considerations’, Remote Sensing of Environment, Volume 275, 2022,113000, ISSN 0034-4257,https://doi.org/10.1016/j.rse.2022.113000

M4Mining is funded by the European Union’s Horizon Europe programme under Grant Agreement ID 101091462. For more information, visit www.m4mining.eu

Please note, this article will also appear in the 19th edition of our quarterly publication.