The Adianano microwave exfoliation method for the synthesis of silicon-carbon nanocomposites for lithium-ion battery production is highly efficient and removes the need for complex equipment.

According to global environmental tendencies, the EU is strongly pushing industries to go green. Everyone understands that climate change is here and mainly caused by CO2 emissions, where the transport sector is responsible for 26% of all greenhouse gas emissions and, inside it, 77% are generated by road transport.

Due to these factors, the automotive sector has shifted its focus to electronic vehicles (EVs). However, there is a lack of sales due to consumer concerns, including that they won’t have enough range to satisfy their needs, since currently used materials inside lithium-ion batteries (LIB), which are the power source of EVs, are used on their maximum level.

Also, the increasing demand for EVs is causing a lot of CO2 emissions during lithium-ion battery production. This can be mitigated if the total capacity and lifespan of the battery is increased.

Current solutions and problems

The performance of a LIB is primarily dependent on the material of the battery’s anode. Currently, graphite is the most popular commercial anode material. However, the relatively low capacity of the material limits its further development. Silicon (Si) based anode materials are a popular candidate for next-generation lithium-ion battery production due to their high-power density.

Silicon is an alternative to graphite as an anode material for lithium-ion battery production. Its theoretical specific capacity is 4,212 mAh/g, while the theoretical specific capacity for graphite is 372 mAh/g.

However, the high initial capacity of composites based on nano silicon rapidly decreases with cycling, which is associated with an increase in its volume up to three to five times during lithiation-delithiation of silicon. Such swelling leads to the cracking of the anode material and disruption of contact with the current collector.

Researchers from different countries have proposed many ways to improve the efficiency of anodes based on nano-silicon.

The downside of nano-silicon in lithium-ion battery production

The mechanisms of LIB degradation are complex and depend on several factors, the main of which is the agglomeration of silicon nanoparticles and its volumetric changes, leading to loss of contact between silicon nanoparticles and carbon material, which leads to degradation of the LIB during cycling.

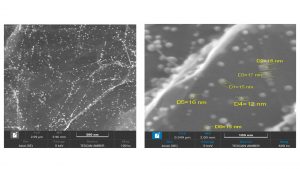

The following image shows how silicon is unevenly distributed in the carbon material and forms agglomerates up to 300 nm in size.

Agglomerates of silicon nanoparticles in graphene

Adianano – The microwave exfoliation method

Our team proposed an original method for the synthesis of silicon-carbon nanocomposites by microwave (MW) exfoliation.

Development of technology for microwave synthesis of silicon-carbon nanocomposites and technological equipment for its implementation

By choosing a precursor, operating parameters of MW radiation, composition, and pressure of the argon-monosilane gas mixture, it was possible to synthesise silicon-carbon composites with:

- A given size;

- Structure (amorphous or crystalline); and

- The quantitative content of silicon nanoparticles, homogeneous (without agglomeration) and distributed over the volume of the material.

Distribution of silicon nanoparticles 12–16 nm in size between graphene layers

Image obtained using SEM (TESCAN), Composite_MLG@n-Si_MV-50

Advantages conclusion

The advantages of the MW method for the synthesis of silicon-carbon (n-Si@MLG) composites are the following:

- Uniform distribution of silicon nanoparticles in the layers of multilayer graphene (MLG) (there is no agglomeration of particles over the volume of the material);

2. The possibility of obtaining composites containing n-Si in a wide range of concentrations (from 5-80%). This makes it possible to synthesise anode materials for LIB with desired characteristics; and

3. The MW synthesis of silicon-carbon composites is carried out in one stage and has a high speed with a 100% yield of the target product.

This will significantly simplify the technology for obtaining n-Si@MLG of a given composition for lithium-ion battery production and increase productivity by creating a production line.

Microwave exfoliation of C2F∙xR in a monosilane (SiH4) atmosphere made it possible to obtain structures from MLG with a uniform distribution of silicon nanoparticles of a given size in the interlayer space of graphene.

The advantages of using Adianano product in LIBs

These aforementioned advantages ensure the stability of the composite against cracking when the volume of silicon changes during cycling (trampoline) and, accordingly, the long-term stability of LIB operation.

Conclusion

A new technology for the microwave synthesis of silicon-carbon composites for LIB has been developed. A distinctive feature is a single-step process in which the exfoliation of the precursor (graphite difluoride) under the action of MW radiation leads to the decomposition of monosilane and the formation of silicon nanoparticles on the graphene layers.

An important result of the research is the ability to control the properties of the target product: the mass content of silicon in the composite, the size of silicon nanoparticles, their phase composition, and distribution in the interlayer space of multilayer graphene.

The main parameters of the process – the type of intercalate, the pressure of the gas mixture containing monosilane, and the power and time of exposure to MW radiation – are selected based on the required properties of the target product.

The proposed method for the synthesis of silicon-carbon nanocomposites provides 100% yield of the target product, does not require complex equipment and highly qualified staff, and can be scaled up and used in industrial production.

Please note, this article will also appear in the fourteenth edition of our quarterly publication.