A team of researchers from Korea Institute of Science and Technology (KIST) has developed a processing technology for amplifying energy densities of high-capacity lithium batteries.

The joint research team is comprised of Dr Minah Lee, Center for Energy Storage Research, and Dr Jihyun Hong, Center for Energy Materials Research, both of the Clean Energy Institute, Korea Institute of Science and Technology (KIST).

When charged in the initial cycle, a battery with a silicon-based anode loses more than 20% of the lithium ions it uses for electricity storage, which results in an issue of reduced battery capacity. To resolve this issue, KIST researchers have developed a method of adding extra lithium before battery assembly to compensate the lithium loss during high-capacity lithium battery cycling. Previous methods of this lithium ‘pre-loading’ use lithium powder, the use of which has safety and price concerns.

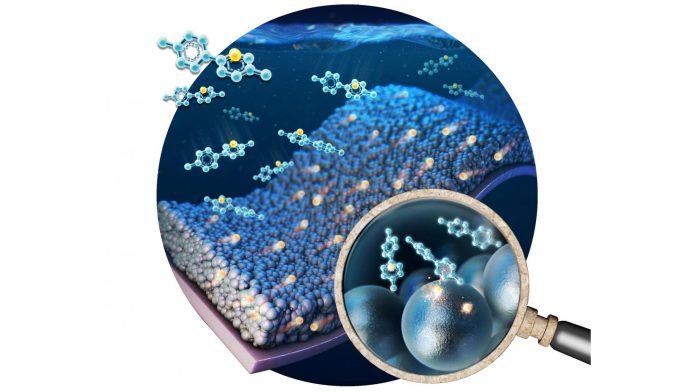

Lee and Hong have developed a technology that enables the pre-loading of lithium ions using a lithium-containing solution rather than the lithium powder, to prevent lithium loss in a silicon-based anode.

Innovation in lithium ‘pre-loading’

Researchers found that by submerging an electrode in the tailored solution for five minutes, the team can achieve a successful lithium pre-loading. Unlike the conventional method of adding lithium powder to an electrode leading heterogeneous lithium distribution, the tailored prelithiation solution rapidly seeps into an electrode ensuring homogeneous delivery of lithium into silicon oxide.

The prelithiated silicon-based anode developed by the research team loses less than 1% of active lithium in the first charge, yielding a high initial battery efficiency of 99% or higher. A battery manufactured with the prelithated anode exhibited an energy density 25% higher than that of a comparable battery using a graphite anode available on the market.

Dr Lee, who headed the research, commented: “By incorporating a computational materials science technique into the design of an optimal molecular structure, we were able to improve the efficiency of a high-capacity silicon-based anode by leaps and bounds with the simple method of just controlling the solution temperature and reaction time. As this technology is readily applicable to the roll-to-roll process used in existing battery manufacturing facilities, our method has potential to achieve a breakthrough in the implementation of silicon-based anodes for practical batteries.”