Innovate UK has announced a £6.6m competition to build a stronger supply chain for critical materials for magnets.

Critical materials for magnets, such as rare earth elements (REE), are essential in a range of technologies, such as manufacturing electric vehicles.

The Critical Materials for Magnets Competition aims to reinforce UK supply chains for these vital resources to put the country at the forefront of the green transition and protect it from volatile global markets.

The competition is backed by the UK Government’s CLIMATES programme, which is backed by £15m funding to advance critical materials supply chains.

Which critical materials projects have been chosen?

The first winners of the Critical Materials for Magnets competition have been announced, with 16 UK projects set to benefit from sizable funding. These include:

- Ionic Recovery Ltd / Imperial College – Recovery of REE from end-of-life mobile phones;

- Seloxium Ltd / Oxford University – Securing a supply of REE from volcanic tuffs for UK magnet manufacture;

- Altilium Metals Ltd / Exeter University – Recovery of REE from mining tailings for re-entry into the UK supply chain;

- Nanomox Ltd / STFC / Green Rose Chemistry Ltd – Valorisation of magnet waste;

- Materials Nexus Ltd / Less Common Metals Ltd – Using Machine Learning techniques to design high-performing magnets with reduced REE;

- Lightning Machines Ltd / Warwick University – Recovery of REE from electric vehicles;

- Magnetic Systems Technology Ltd / Hirst Magnetic Instruments Ltd – Recovery and reuse of magnets from electric vehicles;

- Pensana Rare Earths PLC / Universities of Leeds and Hull / Polestar Automotive / Route 2 Sustainability Ltd – Creating a low carbon, environmentally sustainable, and socially just value chain for rare earth magnets;

- Phyona Ltd / Brunel University – Biomass extraction of REE from coal mines;

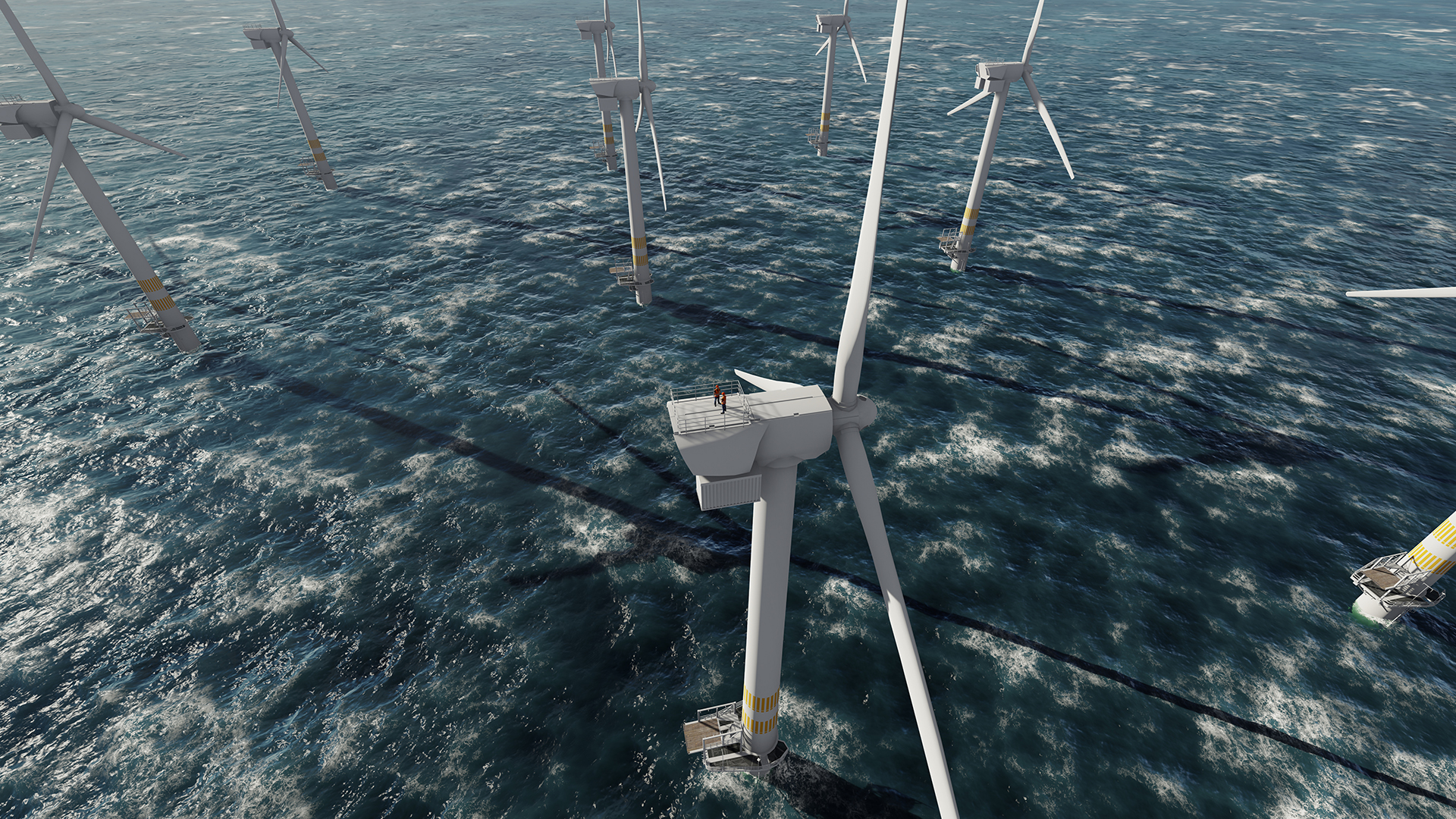

- European Metal Recycling Ltd / Hypromag Ltd / Offshore Renewable Energy Catapult / Magnomatics / Birmingham University – Decommissioning and recycling offshore wind turbines;

- Ionic Technologies Ltd / Less Common Metals Ltd / Ford Technologies Ltd – Creating a circular supply chain for recycled magnets;

- Medallion Innovations / CPI, Minviro Ltd / Siemens Process Systems Engineering Ltd – An innovative separation technology of REE and other critical materials from mixed concentrates;

- Benks Global Ltd / Materials Processing Institute – new process methods for refining REE;

- Minviro Ltd / Exeter University Grundfos Manufacturing Ltd, Mkango Rare Earths UK Ltd – A software tool to strengthen the UK REE magnet supply chain by enhancing and ensuring strong sustainability credentials;

- Ionic Technologies Ltd / British Geological Survey – A feasibility study into the construction and supply side dynamics of a magnet rare earth recycling plant in the UK; and

- GSA / Lincoln University – Recovery of REE from titanium oxide waste.

Overall, there are 40 organisations receiving funding, 27 of which are businesses and 13 are universities or Research and Technology Organisations (RTOs).

Mike Biddle, Executive Director for Net Zero at Innovate UK, commented: “By recycling and recovering valuable rare-earth magnets, we are reducing the environmental impact of extraction, saving energy, and creating a resilient supply chain in a growing global market.

“These materials are fundamental to building a net zero economy, so we need a sustainable way to access these critical materials and for innovation to thrive in harmony with responsible resource management.

“I’m pleased for our competition winners, who have demonstrated their commitment to this by making this happen, and I wish them well on their innovation projects.”

Funding success stories

A groundbreaking initiative that has successfully attracted investment from the Critical Materials for Magnets Competition involves a collaborative effort between EMR, HyProMag Ltd, Offshore Renewable Energy Catapult, Magnomatics, and The University of Birmingham.

This partnership is dedicated to the sustainable decommissioning and recycling of offshore wind turbines.

The initial generation of wind turbines is approaching the end of their operational life, and executing their decommissioning in an environmentally responsible manner presents a multifaceted challenge.

The project aspires to be a vital component of a low-carbon decommissioning strategy, facilitating the recovery of REEs used in the turbines’ construction.

Nick Mann, Operations General Manager of HyProMag, said: “We are very excited about this innovative project and the opportunity to further develop the UK supply chain for rare earth magnet recycling with the support of Innovate UK and an excellent consortium of project partners.

“This project will address the hurdles for recycling permanent magnets from wind turbines, effectively unlocking a new domestic source of rare earths.”

Strengthening REE supply chains

One of the victorious companies is Ionic Technologies Ltd, headquartered in Belfast, renowned for its expertise in recycling magnets to foster the establishment of sustainable and transparent REE supply networks.

This company has achieved funding for two significant CLIMATES projects. In collaboration with the British Geological Survey, Ionic Technologies will conduct a feasibility study for a commercial magnet recycling facility in Belfast as part of one project.

The second project focuses on forging a traceable and circular REE supply chain for EV motors in the UK in partnership with Less Common Metals (LCM) and Ford Technologies.

Thomas Kelly, General Manager of Ionic Technologies, commented: “The funding provided via the partnership with Innovate UK, as well as the opportunity to work with purpose-driven and innovative organisations that the projects are affording, is adding significant value to our business.

“Ionic Technologies is driving the emerging supply chain for REEs and its ability to meet the increasing demand for critical minerals in the UK and abroad. This will enable the UK to meet its net zero ambitions by serving renewable technologies such as wind energy and EV manufacturing.”