Recent developments in silica aerogels present new solutions to the field of advanced materials. With applications in insulation, energy storage, and catalysis, could silica aerogels be a cost effective alternative to graphene?

Silica aerogels are low density solid nanomaterials with a highly porous surface area. Silica aerogels are commonly used in thermal insulation, catalysis, optical devices, and environmental remediation (reducing radiation exposure) due to their ultralow thermal conductivity and open pore structure.

One setback for the wider adoption of silica aerogels is their lack of flexibility. To overcome this, some material scientists strengthen the structure using fibre reinforcements and binders. However, their poor machinability and inability to precisely cast small objects limits their miniaturisation potential for smaller devices.

The synthesis of aerogels

Silica aerogels are produced when liquid is extracted from the framework of silica gel in a way that typically preserves 99% of the gel framework’s original volume. This is often made possible using techniques called supercritical drying and ambient.

Supercritical drying

Supercritical drying can produce silica aerogels by transforming the liquid present in the material into gas. In the absence of surface tension and capillary stress, this procedure can dry silica aerogels without destroying the material’s nanostructured pore network. Supercritical drying is used in other scientific disciplines in order to dry biological specimens, such as insects and amphibians.

Scientists using the supercritical drying method introduce high-pressure or high temperatures to the specimen. This does not cross any phase boundary, instead passing through the supercritical region, where the distinction between gas and liquid ceases to apply.

Ambient drying

Wet gels will experience a large amount of volume shrinkage if dried at ambient pressures because of the large surface tension generated when solvent leaves the structure at the drying step. This results in the collapse of the 3D structure of the wet gel, leading to high apparent densities and low specific surface areas of the final products.

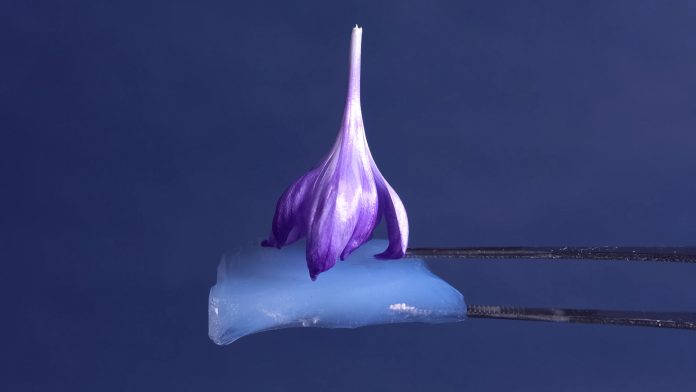

Silica aerogels can be produced by ambient drying using ammonium bicarbonate, generating CO2 and NH3 within the pores of the wet gel, in order to prevent the collapse of the material during the drying process. The high surface tension of ammonium bicarbonate allows for heat to dissociate the solvent generating CO2 and NH3 within the pores of the wet gel, preventing collapse. Researchers at the Swiss Federal Laboratories for Materials Science and Technology were able to use this technique to create silica aerogels for 3D printing, creating silica aerogels as thin as a micrometre.

The use of silica aerogels in energy sciences

Silica aerogels are one of the most efficient thermal insulators, offering 77% less thermal conductivity than other commercial insulators. Silica aerogels can also withstand high temperature fires without disintegration and prevent the temperature on the non‐exposed side from increasing above the critical level for the collapse of reinforced concrete structures. This material holds the potential to reduce fire risk in electric vehicles and other lithium ion powered devices, which are notorious for catching fire when damaged or improperly stored.

Due to its intricate nanostructure and cellular structure, aerogels also demonstrate great success in thermal energy damping and can perform acoustic, electrical, and impact damping. Dr Peter Tsou of NASA’s Jet Propulsion Laboratory sought to collect a sample of comet dust to understand the origins of our Solar System, suggesting that silica aerogel could help catch it. Comets eject a plume of particles and dust which give them their characteristic luminescent tail (or coma). Tsou headed a project called Stardust designed to collect ejected particles from comet Wild 2. Relative to the probe, the impact velocity of the particles ejected from the coma was approximately 6100 m s-1 (13,600 mph). Using blocks of a three-layer gradient density silica aerogel, the Stardust probe was able to safely stop the particles, leaving them embedded in the aerogel collector for extraction and analysis upon returning to Earth.

Growing demand for aerogels

The global aerogel market generated $701m in 2019, and is estimated to reach $1.39 bn by 2027, registering a CAGR of 9.3% from 2020 to 2027. Growing demand for aerogel from automotive, oil, and gas industries due to its high durability and fire resistant properties drives the growth, however, high production costs could reduce the adoption of this advanced material. In a bid to decrease construction costs the European Commission has granted over €1m to the silica aerogel-base project, Svenska Aerogel which has developed a patented process for the manufacture of an aerogel-type material called Quartzene.

The new micrometre-sized material can be marketed at a 50 to 60% lower cost than all other aerogels. “Svenska Aerogel’s new patented methods will allow, for the first time, aerogel insulation to be developed for mass-market applications such as buildings, coatings and disposable food containers,” says Svenska Aerogel’s founder and Head of R&D Professor Christer Sjöström.

The drying process of Quartzene is performed under ambient pressure and low temperature increases. Its production is therefore considerably less expensive than traditional aerogels produced by supercritical drying. “The ambient pressure drying process used breaks solid materials into smaller pieces by grinding. The high air velocity and the small particles help make the drying process quick and energy efficient.

He went on to explain that aside from lowering production costs, the novel drying process can reuse waste heat at above ambient temperatures, improving energy efficiency by up to 90%.