Danish deep-tech company SUBRA has overcome key challenges for superconductors used in fusion systems with a new advanced high-temperature superconductor solution for sustainable fusion energy production.

To achieve Europe’s net zero climate goals and ensure a sustainable energy supply, a transformation in electricity production is required. This involves decarbonising the energy system and significantly reducing reliance on fossil fuels. While wind and solar energy play a major role, they are not enough on their own. Fusion energy emerges as a promising so-called baseload, offering the potential to replace fossil fuels and provide a constant, continuous energy source. However, realising this potential requires advancements in superconductor technology and intense scaling of production capacity – a challenge that SUBRA has taken on.

The promise of fusion energy

Fusion energy as a power source has long been a holy grail within the scientific community, with electricity produced via heating obtained from nuclear fusion reactions that produce no carbon dioxide or harmful emissions, making it a truly green solution for sustainable energy production. While fusion energy has been said to always be 30 years away, the prospects have changed. Recent major technological advancements have greatly accelerated progress in this field, driven largely by game-changing material innovations. Instrumental private investments in over 40 fusion energy companies, exploring several different innovative approaches to fusion, has started the race toward building small and affordable demonstrator reactors already within the next three to five years.

In Europe, the recent establishment of the European Fusion Association (EFA) marks a significant step toward building a robust industrial fusion energy ecosystem, accelerating rapid innovation, and scaling a strong European supply chain for global fusion energy production companies.

SUBRA: Pioneering superconductor technology

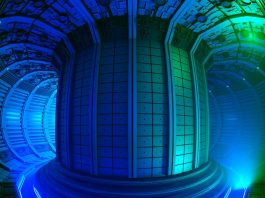

A pioneer in fusion technology development, and one of the founders of EFA, is the Danish deep-tech company SUBRA – a spin-off from the Technical University of Denmark. Founded in 2014, the company has leveraged over 15 years of research to develop high-temperature superconductors (HTS) essential for commercial fusion technology. These superconductors are a vital component in the construction of the powerful electromagnets needed to confine fusion plasma at extremely high temperatures in, for example, tokamak or stellarator fusion reactors.

Despite their importance, present superconductors face challenges, such as energy losses from pulsed magnetic fields, thermal robustness and scaling of low-cost production. To overcome these issues, SUBRA has launched a new type of filamented superconductor tape produced in large-scale production. These are specifically designed for the volume production of fusion magnets using low-cost reel-to-reel processes. SUBRA’s large-scale approach enables cost-effective production of high-performance ceramic superconducting coatings made in parallel stripes on a metal tape. While the coatings are only three micro-meters thick and a few hundred micro-meters wide, they can carry a current 300 times that of an equivalent copper wire. Further, SUBRA’s new solution allows for the required wrapping of the tape in km-production, in order to harness the full benefits of the extremely narrow superconducting filaments – a leap in tech development that will result in enhanced performance and durability of fusion reactors.

What is a superconductor?

- Definition: A superconductor is a material – in the form of a tape, wire, or cable – that conducts electricity with zero electrical resistance when cooled.

- Efficiency: Superconductors can transport vast amounts of electrical power, carrying

300 times more than copper. - Energy loss: Unlike traditional conductors, superconductors experience no energy losses

when transporting direct electrical current.

Looking ahead, SUBRA is developing a new bundled superconductor cable called SUBRACABLE, designed for power transmission. Anders C Wulff, Chief Executive Officer of SUBRA, states: “This innovative cable has the same practical qualities as a traditional bundled copper cable, but its geometry enables a game-changing functionality with extraordinary cost-effective use of superconductors in transmission, not seen until now.”

The compact design of the SUBRACABLE requires significantly less material – 99% less copper – while allowing for high-voltage electricity transmission without the need for multiple transformer stations. Traditional copper cables incur significant energy losses – up to 13% – due to heating during electricity transport. In contrast, superconductors, even when including the required cooling, minimise these losses and can be manufactured cost effectively at lengths exceeding 10km. This can drastically reduce the carbon footprint of power transmission in the EU, where transmission losses currently equate to over 47 million tons of CO2 annually.

The transition to a green energy future necessitates not only a shift in electricity production methods but also improvements in energy transmission. Fusion energy, backed by advanced superconductor technologies, presents a viable path toward achieving Europe’s climate goals. As companies like SUBRA innovate and scale their technologies, the potential for a sustainable, non-carbon-emitting energy system becomes increasingly attainable. This integrated approach could pave the way for a cleaner, more efficient energy landscape in the years to come.

Please note, this article will also appear in the 20th edition of our quarterly publication.