Researchers at the University of New Mexico (UNM) detail technologies that radically enhance the performance of high-temperature thermal-fluid systems to pave the way towards commercialising advanced reactors.

According to the Energy Information Administration’s (EIA’s) 2017 International Energy Outlook, global energy consumption is expected to increase by 28% between 2020 and 2040 (EIA, 2017). Nuclear power plants currently generate 11% of the world’s electricity. It is projected that nuclear power will be the world’s second-fastest-growing energy source and will increase by an average of 1.5% annually between 2020 and 2035. In the US, nuclear power currently accounts for about 20% of all electricity generation and more than 50% of the nation’s total clean electricity.

Nuclear power has been identified as a vital resource to achieve net-zero emissions economy-wide by 2050. Most of the world’s nuclear power is generated by second and third-generation nuclear power plants. Although a significant share of existing nuclear plants will be retired in the 2030s, rising demand for carbon-free electricity from all over the world will stimulate nuclear energy development. To achieve safety, reliability, sustainability, economic competitiveness, and proliferation resistance for future nuclear power, technologies are required to be improved in nuclear energy development. Advanced reactors offer the potential to transform the nuclear power industry, providing safe, reliable, and carbon-free electricity that addresses the plethora of challenges arising from the decarbonisation of power grids worldwide. The US has invested significant effort in new technology development for advanced reactors over the past decade.

SET and IET tests

The development of advanced reactors requires an understanding of integrated and complex systems that exhibit new phenomena under normal, transient, off-normal, and accident conditions (Zweibaum et al., 2015). The phenomenological analysis and thermal-hydraulic behaviours of an advanced reactor form the basis for its design and safety evaluation (Mascari et al., 2015).

Performing meaningful full-scale experiments is expensive, time-consuming, or even impossible within the time and budget available. Scaled-down experimental tests, e.g., separate effects tests (SETs) and integral effects tests (IETs), with proper scaling considerations, are feasible to develop an experimental database to characterise the possible prototype thermal-hydraulic behaviours. System-level thermal-hydraulic codes can then be validated against the database and used for reactor system design and safety analysis.

On the one hand, SETs are conducted to provide experimental data to develop and validate physical models and/or empirical correlations for characterising single local phenomena or combined phenomena under prototypical – or simulated conditions. Since each of these models and correlations may not always scale to the prototype, many physical models and empirical correlations with limited applicability within a small range of conditions are implemented into the system codes that are used to identify thermal-hydraulic responses by simulating various types of accidents and abnormal transients of reactors of interest.

The SET facilities are typically highly instrumented to minimise scaling distortions. On the other hand, IETs are carried out to investigate the behaviours, phenomena, and processes of the entire system, the interactions of two or more components, and the local phenomena that are typical of the overall system design targeted functions (USNRC, 1998). IET facilities can provide the whole dynamic- and similar-thermal-hydraulic responses that may appear through postulated accidents and/or abnormal transients in a reference reactor.

The data obtained from the IET experiments are used for validating system codes and understanding accident phenomena instead of being directly applicable to full-scale conditions of a reference reactor. The number of instrumentation and sensors in an IET facility is less than that of an SET facility. Scaling distortion is inevitable for IETs and can be the origin of uncertainties in the safety analysis. It is, therefore, important to minimise or eliminate the scaling distortion, especially the time scaling distortion, as temporal control is not practicable (Bestion, 2017).

Evaluating molten salt nuclear reactors

There are two molten salt nuclear reactor categories being developed that are gaining growing global interest: fluoride salt-cooled, high-temperature reactors (FHRs) having solid particle fuel with the molten salt used as the coolant only, and molten salt reactors (MSRs) with the fuel dissolved in the molten salt coolant. To evaluate an MSR or FHR design, safety evaluations are carried out to understand the validity and accuracy of computational methods, the sensitivity of results to uncertainties, and the safety margin under varying conditions (Diamond et al., 2018).

It is essential to predict behaviours during normal, off-normal, and accident conditions as there is much less regulatory experience and experimental experience for an MSR or FHR. Numerous experimental data are required for identifying nuclear thermal-hydraulic phenomena, validating computational tools, and performing scaling analyses or even validating scaling methods. SETs and IETs are key to the database for developing and validating system-level thermal-hydraulic codes for licensing an advanced reactor. However, SETs and IETs for MSRs and FHRs are sparse. Many SETs and IETs based on low-temperature surrogate fluids (e.g., heat transfer oil and water) for molten salts provide reasonable scaling strategies and an acceptable methodology (Zweibaum et al., 2020).

Using surrogate fluids can allow for the investigation of relevant fluid and heat transfer phenomena at significantly low temperatures, fewer required resources, use of available and accurate instrumentation and sensors, eliminating molten salt-related hazards. However, some phenomena attributed only to high-temperature liquid salt have not been considered using surrogate fluids, such as overcooling events, overheating events, thermal mixing and stratification, or radiative heat transfer. Overcooling can lead to molten salt freezing phenomena, resulting in component damages that could be significant during transients and accidents. Overheating may affect reactor structure, causing local heating due to flow maldistributions. Parasitic heat losses may also be significantly different between high-temperature molten salts (550 to 700°C) and low-temperature surrogate fluids (50 to 90°C).

For laminar flow, radiation heat transfer is expected to be higher and will need to be calculated and quantified. A number of molten salt test loops are operable in the US (Yoder, 2015; Robb, 2016; Chen, 2021), and all are used to support the development and demonstration of molten salt components such as pumps, seals, valves, and heat exchangers, as well as material corrosion tests. However, no SET and IET molten salt facilities are available to study molten salt accident conditions, and molten salt heat transfer and flow have not previously been thoroughly investigated for FHR/MSR cores (e.g., pebble bed, parallel channels, and rob bundles) under prototypical temperature and fluid conditions. In addition, limited molten salt heat transfer data available with large discrepancies in thermophysical properties have led to misleading conclusions (Holcomb, 2013). It is, therefore, imperative to develop a high-fidelity molten salt flow and heat transfer database for FHR/MSR core and subsystem designs and for accident analyses.

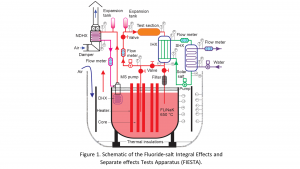

To support SETs and IETs of an MSR/FHR, UNM is conducting a series of innovative molten salt experiments to understand molten salt phenomena, enhance the performance of key components, and validate the system performance and analysis codes. A reduced-scale versatile molten salt test facility with an innovative hybrid loop-pool design is being planned, constructed, and employed for experiments to predict the system performance under normal, transient, and accident conditions. The facility is designed in a way that can perform SETs and IETs with bypass flow loops realising by molten salt valves. Once the facility is completed, experimental data obtained from both SETs and IETs will be used to benchmark the system-level codes. The reduced-scale Fluoride-salt Integral Effects and Separate effects Tests Apparatus (FIESTA), as shown in Fig. 1, is being constructed in The Advanced Thermal-Hydraulics Laboratory at the University of New Mexico that Dr Minghui Chen directs.

FIESTA’s impacts on advanced reactor research

The mission of the FIESTA is to establish a scientific and technical basis for accelerating licensing for MSRs and FHRs along with other experimental facilities in national laboratories, industries, and universities. FIESTA has the capability of replicating most MSR or FHR transient responses for a wide range of events that will be evaluated during the licensing process. FIESTA is designed to operate at 650°C with FLiNaK (i.e., eutectic mixture of 46.5% LiF -11.5% NaF-42% KF) as the primary coolant, corresponding to a typical reactor core outlet temperature. It is expected that this facility will include all the key components in an MSR or FHR, at a reduced scale, except the power conversion cycle, including a vessel, two molten salt pumps, an intermediate heat exchanger (IHX), a secondary heat exchanger (SHX), a direct reactor auxiliary cooling system (DRACS), a vessel cooling system (VCS), and an intermediate loop. The reactor core will be simulated using electric heater rods. In addition to the DRACS, Reactor Vessel Auxiliary Cooling Systems (RVACS), a VCS, where decay heat is removed from the reactor and guard vessel walls by convection and/or radiation, can be easily incorporated and tested (Lisowski, 2021). The simulated heat is transferred to air flowing within the cavity of the concrete containment and rejected to the environment directly, or through a secondary exchange by convection to water. For transients and accident conditions, the electric power will be varied to simulate reactor feedback effects. FIESTA will be fully trace heated and thermally insulated except for the test section.

One of the main purposes of the FIESTA is to gather steady-state and transient experimental data relevant to validating thermal-hydraulic system codes. At this aim, FIESTA features sufficient complexity to be representative of an MSR or FHR design, where strong coupling exists between the thermal-hydraulic behaviours of the reactor core, IHX, intermediate loop, SHX, heat sink loop, and decay heat removal systems (DRACS and/or RVACS). A test matrix will be developed for the FIESTA based on some MSR and FHR nominal operations and transients. Data on the coolant inlet and outlet temperatures, flow rates, pressures and differential pressures across the heat exchangers and simulated reactor core will be obtained. These data will be used to evaluate the coupling of the subsystems. They will also be used to benchmark the heat transfer and pressure drop correlations/models that are used in the current system-level thermal-hydraulic codes for FHRs.

The research programme performing SETs and IETs utilises a versatile molten salt test facility to validate system codes in support of the deployment of MSR and FHR technologies and also provides students from undergraduate to graduate, especially Native American, Hispanic and underrepresented minorities, with various training and educational opportunities of advanced reactors, hands-on molten salt experiments, and instrumentation technologies.

References

- Bestion, D., D’Auria, F., Lien, P., Nakamura, H., Austregesilo, H., Skorek, T., and Zaki, T., A State-of-the-Art Report on Scaling in System Thermal-Hydraulics Applications to Nuclear Safety and Design, NEA/CSNI/R(2016)14, 2017

- Chen, M., Short, M.P., Muralidharan, G., and Prinja, A., Bimetallic Composite (Incoloy 800H/Ni-201) Development and Compatibility in Flowing FLiBe as a Molten Salt Reactor (MSR) Structural Material, NEUP 17-13020, Final Technical Report, December 2021

- Diamond, D.J., Brown, N.R., Denning, R. and Bajorek, S., Phenomena important in molten salt reactor simulations. No. BNL-114869-2017-INRE. Brookhaven National Lab. (BNL), Upton, NY (United States), 2018

- Holcomb, D.E., Flanagan, G.F., Mays, G.T., Pointer, W.D., Robb, K.R., and Yoder Jr., G.L., Fluoride Salt-Cooled High-Temperature Reactor Technology Development and Demonstration Roadmap, Oak Ridge National Laboratory, ORNL/TM-2013/401, 2013

- Lisowski, D., Lv, Q., Alexandreanu, B., Chen, Y., Hu, R., and Sofu, T., Technical Letter Report: An Overview of Non-LWR Vessel Cooling Systems for Passive Decay Heat Removal, ANL/NSE-21/3, 2021

- Mascari, F., De Rosa, F., Nakamura, H., Umminger, K., and D’Auria, F.S., “Scaling Issues for the Experimental Characterization of Reactor Coolant System in Integral Test Facilities and Role of System Code as Extrapolation Tool,” In 16th International Topical Meeting on Nuclear Reactor Thermal-Hydraulics (NURETH-16), pp. 4921-4934, 2015

- Robb, K.R., Mulligan, P.L., Yoder Jr, G.L. Smith, K., and Massengale, J., Facility to Alleviate Salt Technology Risks (FASTR): Preliminary Design Report with Failure Modes and Effects Analysis. No. ORNL/TM-2019/1370. Oak Ridge National Lab. (ORNL), Oak Ridge, TN (United States), 2019

- U.S. Energy Information Administration (EIA), Annual Energy Outlook 2017: With Projections to 2040. Government Printing Office, 2017

- USNRC, NUREG/CR-5809, “An Integrated Structure and Scaling Methodology for Severe Accident Technical Issue Resolution,” Appendix D, “Hierarchical, Two-Tiered Scaling Analysis,” (ADAMS Accession No. ML063400263), November 1991

- Zweibaum, N., Bickel, J.E., Guo, Z., Kendrick, J.C., and Peterson, P.F. “Design, Fabrication and Startup Testing in the Compact Integral Effects Test Facility in Support of Fluoride-salt cooled, High-temperature Reactor Technology,” In International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-16), Chicago, IL, August. 2015

- Zweibaum, N., Blandford, E., Gerardi, C., and Peterson, P.F., “Scaling Methodology for Integral Effects Tests in Support of Fluoride Salt–Cooled High-Temperature Reactor Technology,” Nuclear Science and Engineering 194, no. 8-9, 202

- Yoder Jr, G.L., and Aaron, A., High-Temperature Fluoride Salt Test Loop, ORNL/TM-2012/430, Oak Ridge National Laboratory, Oak Ridge, TN, 2015

Please note, this article will also appear in the thirteenth edition of our quarterly publication.