Meet the invisible electrical devices which particularly focus on transparent power generators.

Our lives can expect to undergo drastic changes if an electrical function is added to transparent materials such as windows and daily-use plastic bags. Motivated by this idea, we have fabricated novel invisible electrical devices, which particularly focus on transparent power generators. The most promising is a transparent solar cell device; its power conversion efficiency (PCE) is lower than a conventional Si-based solar cell because of its high transparency to sunlight.

Nevertheless, solar cells with such low PCE can be utilised to create energy in diverse areas of our environment where it is not being used currently, such as fabricating windows, the front glass of cars, display screens of PCs and cell phones, eyeglasses, and even on human skin. We believe that this invisible power generator can strongly contribute to establishing an environmentally friendly future for all of society.

For the realisation of a transparent solar cell device, it is necessary to prepare transparent electrodes, transparent substrates, and transparent semiconductors. In terms of electrodes and substrates, there are already established suitable materials such as indium tin oxide (ITO) and glass. However, suitable semiconductor materials have not been established yet. Worldwide, researchers are now seeking new semiconductor materials suitable for solar cell devices.1 Particularly for highly transparent materials, where the transparency exceeds 80%, almost no suitable materials have been reported thus far. Therefore, we focus on atomically thin 2D materials. Graphene is the most well-known 2D material, with a transparency of approximately 97.5% in the visible light range.2-4 However, power generation under sunlight is not possible due to its zero-gap features.

Transition metal dichalcogenides (TMDs) are other kinds of 2D materials.5 In contrast to graphene, TMDs exhibit a clear band gap. TMDs with thicknesses of less than 1nm show strong light-matter interactions, allowing the absorption of incident sunlight to as much as 5-10%, which is one order of magnitude higher than that of common semiconductors such as GaAs and Si.6 These features make TMDs among the most attractive materials for high-performance, transparent, and flexible solar cells. Here, we introduce our recent progress on the integrated synthesis of single-crystal TMDs7 and their transparent solar cell applications.8

Growth mechanism and large-scale integrated growth of TMD

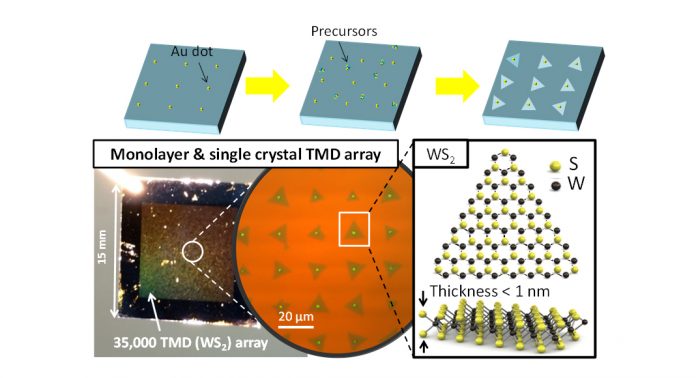

Obtaining a better crystal is vital to improve the device performance. For TMDs, it is still a challenge to grow high-quality single crystals on a large scale, owing to the growth dynamics for TMDs. It is thought that TMD growth basically follows the diffusion growth model, where precursors are supplied from vapor to the substrate, following which the precursors diffuse on to the substrate, nucleation occurs somewhere on the substrate, and TMD growth takes place from the nucleation centre. Despite recent progress in the production of TMDs, the detailed growth dynamics, especially precursor diffusion and nucleation, has not been revealed yet. To clearly identify the dynamics during such a nucleation phase, it is very important to control the nucleation site. In this stage, we established a unique method to control the growth site of single-crystal TMDs with Au dots as a nucleation promoter. A nanoscale Au dot array was fabricated via electron beam lithography and CVD growth was carried out for the pre-Au patterned substrate. The nucleation of the monolayer and single-crystal growth of TMD occurred selectively from the Au dot (Fig. 1).

Subsequently, using this nucleation site control technique, we attempted to experimentally measure the diffusion length of precursors on the substrate (Ld). We found that the Ld of the precursors reached ~750 μm, nearly two orders of magnitude longer than that of conventional semiconductors such as Si, GaAs, and SiC. This ultra-long diffusion was attributed to precursor droplets observed during the in-situ monitoring of TMD growth.7

Based on our growth model, precise adjustments of the Au dot size, Au dot inter-distance, and growth temperature were made in a combinatorial experiment. These systematic adjustments provided the conditions required for the integrated synthesis of single-crystal TMDs, which was governed by a balance between nucleation probability and single-crystal growth. Under the most suitable growth conditions, over 35,000 of integrated single crystals of TMD were grown on a 1.5 cm × 1.5 cm region that covered the entire substrate (Fig. 1).7

Transparent and flexible solar cell with few-layered TMDs

As relatively highly crystalline TMDs can be grown on a large scale by our method, we attempt to fabricate a transparent solar cell with TMDs. The fabrication of solar cells using TMDs has been investigated by many research groups; almost all researchers use pn- or hetero-junction solar cells, which require the use of complicated device structures and fabrication processes, in turn restricting the device size to the micrometer scale. Hence, developing a scalable method with mono- or few-layered TMDs on a transparent, flexible substrate is required to realise semi-transparent and flexible solar cells with true 2D materials. The Schottky-type solar cell has a simple structure, whereby it is possible to scale up the device to the industrial wafer scale. Despite this technical advantage, a detailed study of solar cells containing mono- or few-layered TMDs has not yet been carried out.

Moreover, because a Schottky barrier is formed at the contact region between an electrode and a TMD, it is important to use appropriate electrode pairs for the left and right electrodes (asymmetric electrodes). We investigated in detail the effects of various device structures (different combinations of left and right electrodes and the distance between the electrodes) and TMD morphologies (‘on the substrate’ or ‘suspended’) on the photovoltaic features of the solar cell, to obtain better device performance. By varying these factors, we achieved the fabrication of Schottky-type solar cells with few-layered TMDs. The solar cells fabricated on a SiO2 substrate demonstrated a high PCE of ~0.7%, which is the highest for solar cells with thin (below 3L) TMDs. In addition, the scalability of our method is also demonstrated through the fabrication of solar cells with few-layered WS2 on a centimetre-scale SiO2 and flexible substrate, where clear power generation is demonstrated (Fig. 2).8

However, several issues remain, such as improving the crystallinity of TMDs in the production stage and increasing the PCE and stability in the fabrication of solar cells. However, we believe that our approach for the fabrication of an invisible power generator with 2D materials has immense potential to transform our daily life in the near future.

References

1 C. J. Traverse, R. Pandey, and M. C. Barr et al. 2017. Nature Energy 2:849

2 K. S. Novoselov, A. K. Geim, and S. V. Morozov et al. 2012. Science 306:666

3 T. Kato and R. Hatakeyama. 2012. Nature Nanotechnology 7:651

4 H. Suzuki, T. Kaneko, and Y. Shibuta et al. 2016. Kato, Nature Communications 7:11797

5 B Radisavljevic, A Radenovic, and J Brivio et al. 2011. Nature Nanotechnology 6:147

6 M. Bernardi, M. Palummo, and J. C. Grossman. 2013. Nano Lett. 13:3664

7 C. Li, T. Kameyama, and T. Takahashi et al. 2019. Scientific Reports 9:12958

8 T. Akama, W. Okita, and R. Nagai et al. 2017. Scientific Reports 7:11967

Toshiaki Kato

Associate Professor

Department of Electronic Engineering, Tohoku University

+81 22 795 7046

kato12@ecei.tohoku.ac.jp