Ion-Targeting Direct Extraction technology is a radically new approach to the commercial extraction of lithium and other metallic ions from brines and liquid solutions.

Next-ChemX Corporation has recently announced the development of a cutting-edge extraction technology that operates to concentrate selected ions by drawing them out of a solution across a special purpose membrane. The technology is known as ‘ion-Targeting Direct Extraction’ (iTDE).

iTDE is capable of efficiently extracting metallic ions such as lithium from liquids such as brines with very low concentrations of the targeted ions. In this article, we explore the ion-Targeting Direct Extraction technology’s design, advantages, applications, and its potential implications for the extraction industry.

Problems with the existing mining extraction industry

There is only a finite number of resources on the planet. Yet, new technological developments necessitate an ever-increasing demand for the most important of these resources, such as lithium and other metallic elements. One of the biggest challenges facing the mining industry at this moment is how to increase output while reducing the waste of these valuable resources. This must be done without significantly damaging the environment and in a sustainable fashion.

The mining industry has traditionally been very wasteful in its production methods. This is highlighted by the fact that mines that were considered fully spent some decades ago are found to still be once again commercially viable with the application of better extraction technologies. However, even with these modern technologies, extraction efficiency rates of less than 70% are still considered acceptable.

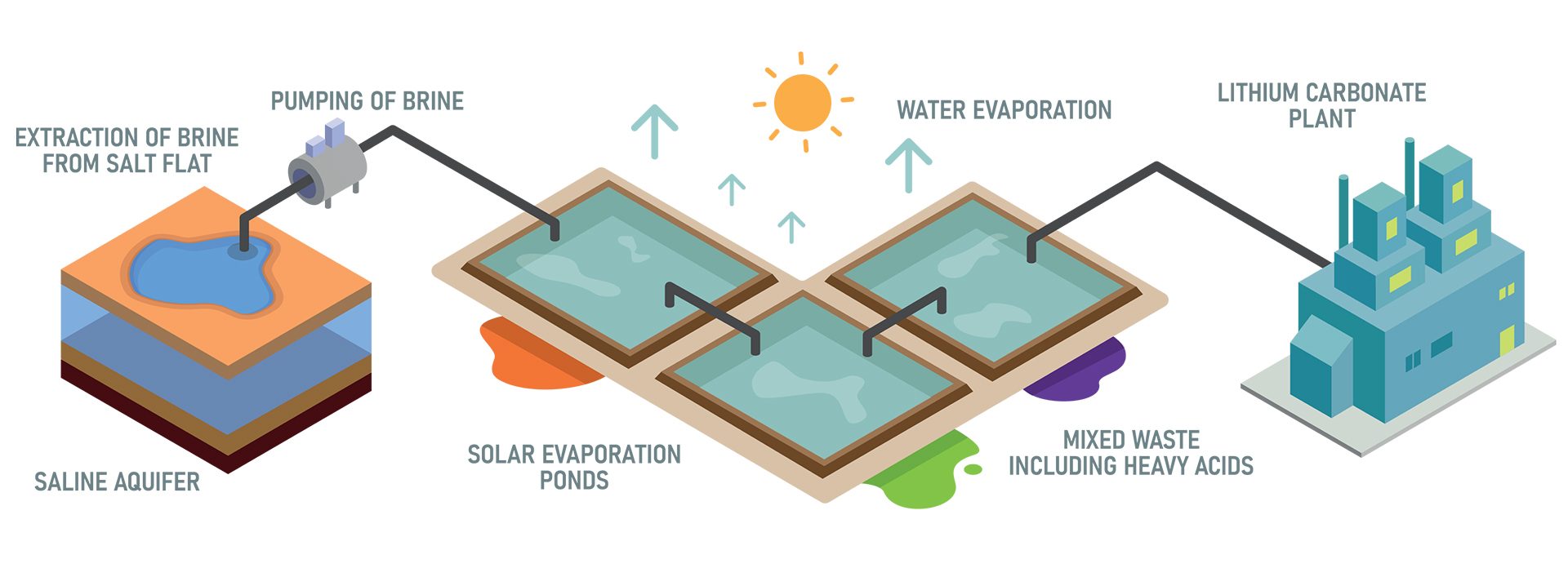

This problem is even more pronounced when the valuable elements are in very low concentrations, even when using the most modern extraction processes. For example, we find commercially deployed extraction methods in general use today, such as evaporation ponds and chemical precipitation, have proven to be only 60% efficient in extracting the desired elements.

The use of some chemicals necessary for such processes can compromise some of the value of the remaining 40% while additionally causing environmental damage that is increasingly viewed as unacceptable.

The entire industry is faced with the challenge of how to address the three fundamental problems crucial to a modern approach to extraction:

1) Delivery of 100% efficiency in brine extraction;

2) Without increasing or lowering production costs; and

3) Minimising environmental impact.

The solution to this triple requirement, developed by NEXT-ChemX Corporation, is iTDE.

What is ion-Targeting Direct Extraction technology?

iTDE works using a selective extraction membrane technology that mimics the structure of natural channels in living mammalian systems. These systems have been developed over millennia under the evolutionary pressures of natural selection and have consequently evolved to be inherently efficient.

iTDE is a proprietary system with patents pending that does not require high pressure, high temperatures, or electrolysis. It is not a traditional selective solvent extraction method and does not employ ion exchange resins. While iTDE does employ certain specially designed membranes, it does not use a high-pressure reverse osmosis membrane system.

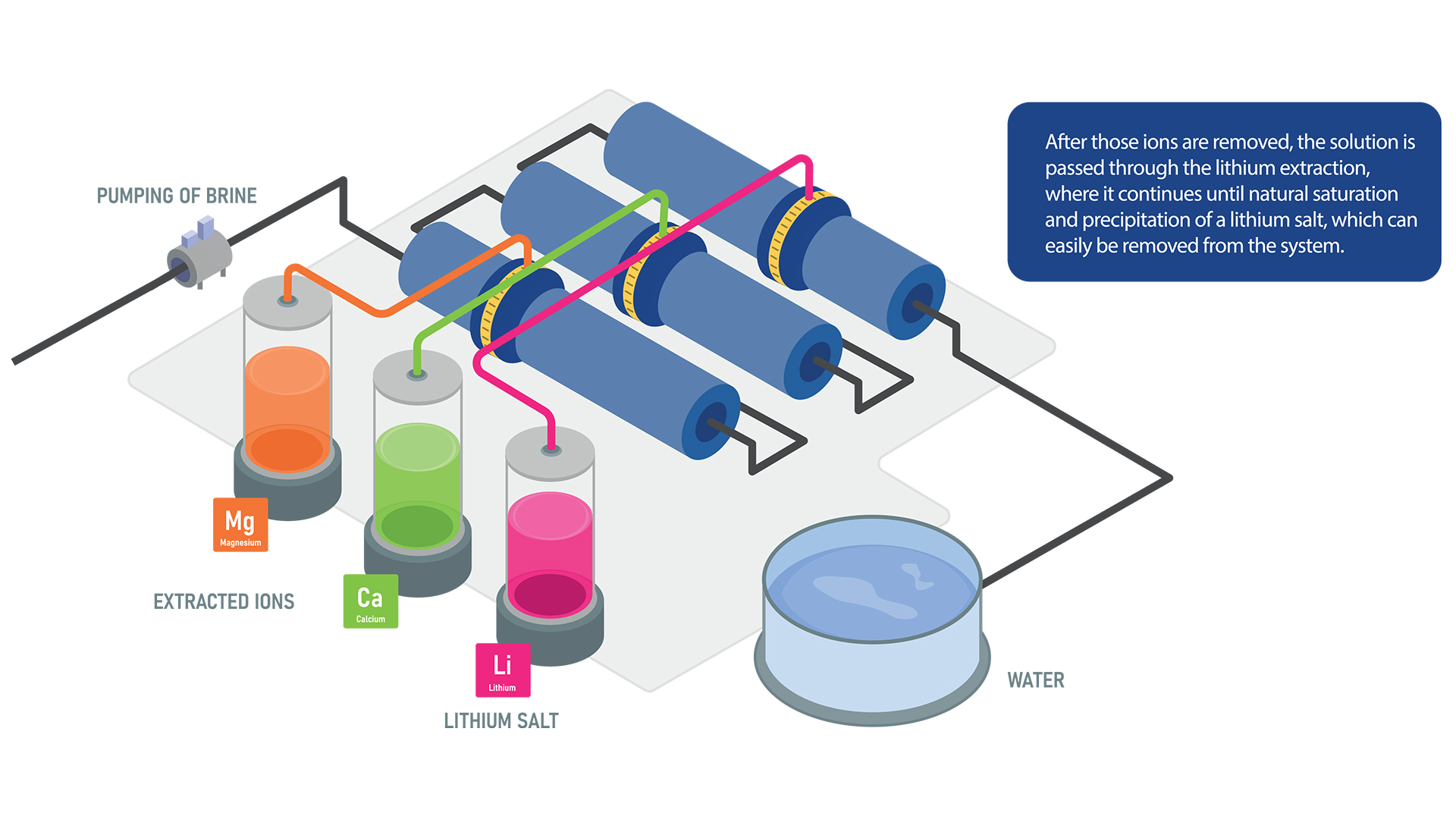

In our ion-Targeting Direct Extraction technology system, the feed liquid containing the targeted materials does not touch or mix with the extracting solution. Ions are extracted using a special very high surface area membrane along with a specific extractant for each targeted ion. This means that the brine feed solution remains within the iTDE closed system until a quantity approaching 100% of the valued commodities are extracted from the feed liquid.

Our technology has already been proven to extract lithium, magnesium, calcium, strontium, nickel, and copper among other ions.

By the very nature of the iTDE system’s operational process, it is completely ‘scalable,’ operating in a modular fashion that allows additional membranes to be added to increase performance. The more membrane modules that are applied, the greater the extraction capability providing the ability to manage large commercial operations.

iTDE is a targeted solution

Ion-Targeting Direct Extraction technology is an engineered chemical solution to the problems of modern-day mining. Since each brine or leach solution has its own specific composition that is dependent at the outset on the geology in which it was formed, and since iTDE targets different ions in specific ways, each iTDE system is optimised for a particular brine or leach solution. In addition, the system provides the flexibility to concentrate more than one ion system potentially generating additional revenue potential.

As a result, our chemical engineering team tailors each deployed iTDE system to each individual customer’s liquid composition and commercial plan. iTDE systems are configured to selectively remove the ions required by each particular customer. As a result, the deployment of the system follows a required path.

First, customers should supply samples of the feed liquid that must be sent to the company’s laboratory for testing. These samples are then processed through the company’s pilot plant to generate extraction data used in designing a solution to fit the customer’s requirement. At present, the company is completing the construction of its improved commercial pilot plant, which is anticipated to be operating in the third quarter of 2023 in Austin, Texas.

The decisive factor and a key advantage in commencing with this process of analysis is that it enables all of the potential value in the brines to be studied so that the extraction process can be optimised with customer input. This allows for the construction of a system that will extract not only the primary desired element contained in the brine or liquor but also potentially secondary, tertiary or even more commercially valuable elements that have their own particular markets. In this way, our unique system can maximise the return of every element of value contained in the customer’s solution.

At this stage of deployment, our team can work out the extraction kinetics of the customer’s particular requirements. Preliminary economic feasibility defining operating costs can also be provided. Once scale is defined, the capital costs of deployment to implement an iTDE system with specific performance targets can be supplied.

iTDE in commercial operation: Market launch

In March 2023, NEXT-ChemX announced a Partnership with Clontarf Energy plc, a UK company, seeking to use our iTDE technology in Bolivia. The goal is to commercialise the extraction of lithium and other ions from Bolivia’s massive brine salars. Bolivia is known to have the world’s largest quantity of lithium-containing brines. However, they are mostly unexploited due to many factors, including very high magnesium content, rainfall which makes evaporation ponds inefficient, as well as environmental sensitivity.

These defining Bolivian issues, which represent difficulties for the use of traditional systems, are mitigated by using the ion-Targeting Direct Extraction technology system; moreover, even the high content of magnesium could be extracted as a valuable by-product. Our system operates to selectively extract very pure ions, resulting in a very concentrated metal salt.

Samples are being prepared in Bolivia to be sent for preliminary testing in our laboratory pilot systems. Upon determining the best configuration for each specific brine sample, we will design a specific system that will process very large samples for conclusive testing through our commercial pilot plant. After successful pre-feasibility economic analysis, a scaled-up commercial pilot plant system would be deployed to the site for a total proof of concept prior to engineering the full-scale commercial plant.

NEXT-ChemX has also held advanced discussions with lithium projects in both Argentina and Chile, and is commencing discussions with projects in Nevada and Utah in the US, as well as in Europe.

iTDE advantages

Ion-Targeting Direct Extraction technology offers several advantages over traditional extraction methods:

Higher efficiency: iTDE can extract almost 100% of the targeted ions from liquids, even with very low ion concentrations, making it a more efficient solution compared to traditional methods.

Continuous process: The iTDE system is a continuous process and does not have the problematic issues of a ‘batch’ process, as found in liquid solvent extraction or selective ion resin extraction.

Low energy use: Since the iTDE system does not need a high pressure or high temperature, the energy consumption is low compared to other methods of extraction.

Cost-effectiveness: The technology necessitates less infrastructure and has lower operating costs than traditional extraction methods, resulting in cost savings.

Environmental benefits: iTDE eliminates the need for evaporation ponds and their harmful side effects of water loss and chemical waste pollution. Additionally, iTDE reduces the environmental footprint of the extraction process.

Water present in brine: After extraction of the targeted ions, the remaining brine can either be reinjected into the salar or further purified to produce agricultural water or even potable water.

Low water use: Since our process extracts ions directly from brine feedstock, there is very little need for freshwater since there is water in the brine. We only require the feedstock to be an aqueous solution in the case of brines or leach solutions.

Flexibility: Our technology can be applied to extract various ions from different types of liquids, making it a versatile solution for the extraction industry.

Valuable by-products: Our technology allows the extraction of other targeted ions, such as magnesium if it exists in high concentrations, which may be very valuable to offset the primary targeted ion extraction costs. Other ions that may be valuable from certain brine locations include potassium, etc.

High-purity ion extraction: iTDE produces very high-purity extractions of the targeted ions, which allows us to produce any number of secondary products, such as lithium carbonate, lithium hydroxide, lithium phosphate, or lithium metal. The same is true for producing pure magnesium metal, especially in the case where magnesium exists in high concentrations, such as Bolivia.

iTDE technology potential applications

Ion-Targeting Direct Extraction technology has a broad range of other developed and developing applications, including:

Lithium extraction: The technology can efficiently extract lithium from brines, making it an invaluable system to economically supply lithium for the rapidly expanding electric vehicle and battery industries.

Mining industry: The technology can be applied to extract valuable elements from mining leach solutions as well as mine waste and tailings, reducing environmental damage and increasing valuable resource recovery.

Battery recycling: Since iTDE can selectively extract battery metals continuously, batteries could be dissolved in a solution passed through our technology system.

Radioactive water treatment: iTDE can be used to remove radioactive isotopes such as strontium and caesium from nuclear wastewater sources, enhancing water quality and safety.

Rare earth metals: iTDE can be used to extract rare earth metals from solutions derived from mine leach solutions or the recycling of materials containing rare earth metals.

Vegetable oil refining: iTDE can remove fatty acids from vegetable oils in a quick continuous process to refine such oils economically without mixing in traditional batch processes.

Biodiesel: iTDE can remove all the glycerides from biofuel production in a continuous quick process, instead of the common batch processes typically used.

Water treatment: iTDE could potentially also remove salts from seawater and brackish waters.

Next ChemX: The company behind iTDE

NEXT-ChemX Corporation is a Nevada corporation, trading as ‘CHMX’, on the OTC Market in the United States.

Our company is based upon its founders’ previous successes in materials science and process engineering, which years ago developed, among other things, the first commercial aluminium-scandium alloys and processes to extract low concentrations of scandium from complex ores and certain industrial process tailings. Those scandium alloys are still the strongest light aluminium alloys and are used in many applications in aerospace, defence products, commercial planes, and sports equipment.

Our founders have also developed liquid mining technology to extract potassium and magnesium from brines created by pumping seawater into carnallite deposits underground. We are building on our experience in scalable processes that are commercially feasible.

The development of the ion-Targeting Direct Extraction technology by NEXT-ChemX Corporation has the potential to disrupt and revolutionise the extraction industry. By offering a more efficient, cost-effective, and environmentally-friendly solution, iTDE can significantly change the way companies extract valuable elements from liquids even when they exist in very low concentrations.

For more information on NEXT-ChemX and our ion-Targeting Direct Extraction technology, please contact: info@next-chemx.com

Please note, this article will also appear in the fourteenth edition of our quarterly publication.