New sensor technologies in food packaging could help to reduce global food waste, as Is it fresh explains.

Did you know that one-third of the food produced worldwide is wasted? According to the study by the UN Food and Agriculture Organization, this amounts to 1.3 billion tons of edible food thrown away every year. Not only the alarmingly large amount of food wasted, but also the various ways of wasting it, are the main reasons for concern. Nowadays, in a globalized world, the transportation of produce from a production site to worldwide markets often implies crossing borders and even continents. During the logistics stage of a product’s journey, a significant amount of food losses results from the inefficient management of food and perishables in general, such as:

- Inadequate temperature control;

- Mishandling of products; or

- Packaging defects.

As food is distributed to retail stores and supermarkets even more waste is generated. The end consumer is, of course, also guilty of contributing to the growing mountain of food waste. How often do we find food lurking in the corner of a refrigerator that has long passed its expiration date?

As a rule, we also throw away foods that passed the expiry date indicated on the package (based on manufacturer’s overcautious estimations), being unaware that the product is most probably still safe to eat. Food waste manifests in different forms and amounts throughout the entire value chain. A great share of the problem can probably be mitigated by building awareness and increasing efficiency of the single processes in the value chain. Yet, considering the complexity of the food industry, these measures alone would not be sufficient, which calls for a more holistic approach for all participants.

The key to preventing food waste: freshness tracking

To better understand the food waste problem, it is helpful to consider food as a commodity and compare it to other industries. First of all, waste of commodities or resources is obviously not limited to food or perishables. There are multiple related examples from the world of apparel or consumer goods. Out-of-fashion clothes, recently purchased furniture and electronic gadgets are disposed of, falling victim to consumerism and having hardly fulfilled their intended life cycles.

As a consequence, inefficient use of commodities results in the waste of valuable resources. Unwanted clothes and furniture can be reused, upcycled and recycled in multiple ways. For example, old jeans can be upcycled into trendy bags, or the fabric can be utilised to make other clothing items. Alternatively, clothes swaps or donation schemes can help re-distributing the surplus production. The same approach can be applied to furniture.

Food is different from other commodities by the sheer fact of its internal and rapidly ticking clock – freshness. Unlike food, clothes and furniture, as well as other non-perishable ‘waste’ items, do not undergo rapid spoilage or “depreciation”, therefore, having much longer life cycles and shelf lives that can be prolonged with proper handling and care.

Additionally, the quality level is, in many of the aforementioned cases, easily accessible for the owner and can be identified by just looking at the product. Most importantly, a wrong assessment of the quality typically does not induce a physical sickness, as in the case of spoiled food. Food as a commodity, on the other hand, depreciates quickly and has a rather limited lifetime post-production and is an intrinsic danger to the owner. Hence, food freshness serves as a real-time indicator of quality and the remaining lifetime, at the same time directly correlating with the value of said product.

The Is it fresh solution

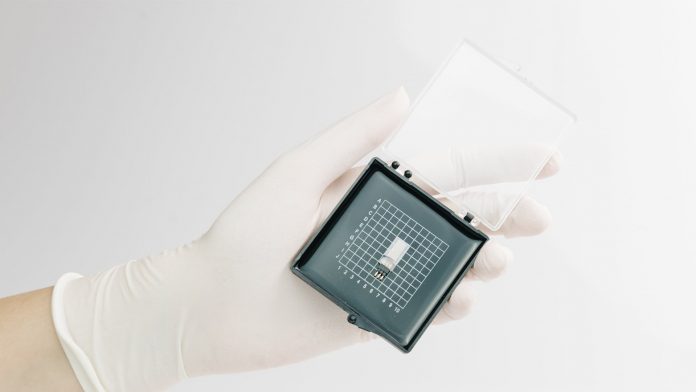

Is it fresh is a German start-up active in the field of sensors and Internet of Things (IoT) solutions. With a wide range of application areas applicable to its technology, Is it fresh focuses on the food waste problem to make a real impact with a digital freshness solution. The team intends to solve the food-specific problem of ‘freshness’ in a unique way. The company’s key product is an ultra-low-cost sensor technology, the ‘freshtag’. The freshtag can check actual food freshness at any given time based on actual measurements of food quality parameter. The food quality and the freshness parameters are measured by a variety of printed sensors; the freshtag integrated sensors offer wireless connectivity and a cloud data storage platform. Consequently, freshtags make it possible to digitalise and trace the individual packaging, measuring freshness parameters at the same time.

Is it fresh provides a solution answering all of the following questions:

- Can we capture and manage the freshness history of a product in the entire food value chain – from the field or the production site all the way to the end consumer?

- Can we identify the points at which the cold chain is broken?

- Can we manage the inventory based on the actual freshness level, rather than on the simple first-in-first-out approach?

- Can we minimise the share of waste related to premature disposal or misinterpreted freshness of food products?

- Can we prevent the risk of food scandals originating from sales of spoiled products?

The ultra-low-cost sensor, freshtag

The major inherent entry barrier of the food industry is the extreme cost pressure of the final product. Available IoT solutions fail to comply with this requirement, even if stripped of all sensing features except from its unique identifier. Besides, most solutions on the market do not offer any approaches to measure the actual freshness of a product directly. Even fewer to none are actually digital and don’t rely on analog solutions.

Is it fresh has realised a true mass market IoT device. The uniqueness of the Is it fresh solution – the powerful sensing platform – measures a variety of food freshness related parameters, while costing only a few cents. The ultra-low-cost freshtags sense real, physical and chemical parameters such as:

- Temperature and humidity;

- Oxygen and carbon dioxide;

- pH; or

- Ascorbic acid.

Is it fresh redefines the boundaries of disposable chip technology to the Internet of Everything (IoE).

A technical overview of Is it fresh

Since 2011, Is it fresh, a spin-off from the Forschungszentrum Jülich in Germany, one of Europe’s largest research centers and a member of the Helmholtz Association, has been developing printed wireless freshtag technology, aiming at making packaging smart. By combining proprietary sensor technology with the low-cost near-field communication (NFC) tags, Is it fresh enables extremely facile wireless communication with smart packaging – any smartphone or other NFC-enabled device can be used for the readout of freshness from a single package in real time.

The two founders of is it fresh, Alexey Yakushenko and Jan Schnitker, have been working on the technology for the last seven years. After years of fundamental research, a technological base was established encompassing:

- Functional inks;

- Unique printed sensors; and

- Versatile manufacturing methods.

The combination of these technologies results in a sophisticated device which can be manufactured for the cost of less than 1% in mass production. It is cheap enough to be integrated into almost every type of packaging. The freshtag will communicate via NFC and can be read out either via phone on the end consumer side or with our industrial readers, or readout infrastructure from partnering companies which can be used for example for retail.

The Is it fresh solution is based on the following three key elements:

Freshtag

The printed, chip-based sensor attached to the package is used to monitor the freshness status of products in real time. The sensor can be placed on the outside of the package (only ID and temperature) or in direct contact with the packaged contents, performing physical and chemical measurements such as:

- Temperature;

- pH;

- Humidity;

- Concentration of ascorbic acid;

- Dissolved oxygen; and

- Hydrogen peroxide.

Consequently, based on the acquired data, the algorithms can determine an actual, dynamic expiration date for a certain product. These parameters can now be measured continuously and, hence, generate trackable data that will enable analyses of what has happened and what will happen with the product. It will also deliver invaluable shopper insights, allowing customer profiling and targeted marketing. The freshtag represents the technological core of the solution and is a proprietary technology.

Smart shelf, smart fridge

The freshtag communicates wirelessly via the NFC standard with omnipresent readout devices, such as smartphones or newly emerging smart shelves and fridges. The sensors are constantly reading the relevant parameters. The NFC-enabled smart shelves can also be retrofitted for existing fridges or shelves at home, in supermarkets or delivery vans. A smart shelf will be able to automatically read out multiple items at the same time with a set time interval.

The shelves are connected to a cloud which happens in a fully-encrypted manner for full data protection and integrity. The processed data will be provided to the customer in a user-friendly way on modern user interfaces via our dashboards and apps. Smart shelves can be implemented in different ways along the value chain. In retail stores, they will function as a ‘bridge’ between freshtags and electronic pricing and management systems.

Utilising cloud computing technology

The freshtag data is processed through and accumulated in a cloud, which can be accessed through an open-source application interface (API) provided by Is it fresh. This API will be made available to all the parties in the food value chain. Each customer integrating the API into their own solutions, or an end user scanning the product, will have different incentives to use the acquired data and, therefore, execute the API calls.

A person will be able to track the quality of the products, assessing the actual freshness status in real time. Suppliers will use data to optimise logistics processes and operations, while reassuring the consumers that the products are of verified origin and high freshness. The access would be free to individual end users, while commercial business to business clients will be charged.

Applying the freshtag to food products

Is it fresh wireless sensor technology will enable affordable food freshness data on a single packaging unit scale. Every package will be able to report its freshness in real time. This will provide each customer with a product that is unique and wirelessly accessible. Through digitalisation, enabled by the Is it fresh technology, freshness management in logistics and distribution industries would be completely automated, reducing their costs.

Moreover, the food quality control and freshness management can be revolutionised. At the moment, food quality control is performed via batch analysis of random samples. As opposed to this, products equipped with freshtags can report the real-time freshness of every single package. In fact, Is it fresh is already partnering with major food manufacturing, packaging and distribution companies, seeking a digital freshness solution.

SME Instrument Phase 2 funding for the Is it fresh solution

In early 2018, Is it fresh applied for SME Instrument Phase 2 research funding, part of the European Council’s Horizon 2020 programme. Through the framework of this funding vehicle, every year promising young companies, expected to bring disruptive innovation to the market, receive a grant of up to €2.5 million. Is it fresh was awarded the financing and was recognised as a high-potential start-up with all the necessary capabilities to contribute to the radical innovation and make a sound impact on the European market and beyond.

IoT beyond food: opportunities for Is it fresh

Is it fresh technology can become a key enabler in the global fight against food waste. However, use of the technology is not limited to this task. A unique identifier, sensors and wireless transmission are the very essence of IoT solutions. Is it fresh can fill the niche for every application requiring a combination of these technologies at a price prohibitive for conventional electronic devices.

IoT: barriers to entry

The McKinsey report on IoT, The internet of things: mapping the value beyond the hype, states that ‘for widespread adoption of the Internet of Things, the cost of basic hardware must continue to drop. Low-cost, low-power sensors are essential.’ This is consistent with the need for a low-cost sensor to digitalise previously analog objects and to implement IoT in multiple markets and application scenarios. Hence, low-cost sensors are considered the main IoT enablers. However, they are also considered entry barriers at the same time, especially in instances where the cost of a device cannot break the threshold set by a specific application.

As the cost of high-performance computers and IT machinery has fallen, driven by the Moore’s Law, application have expanded to everyday activities, far beyond the original use cases of aeronautic and space engineering. Similarly, lowering the cost of sensors would be a breakthrough enabling digitalisation of many objects previously ignored by the IoT community and would pave a path toward IoE. The possibilities for low-cost sensors are indeed endless. Can you imagine how our world would be transformed?

Problems ahead: practical applications of IoT

Let’s say this IoT approach is applied to wine production in Rioja province, Spain. One can digitise information about individual wine bottles or collect digital information based on a crate that contains dozens of bottles of wine. In case of individual bottles, the information about geolocation, temperature and humidity can be collected. Wine data can be collected starting from the Rioja province, through various stages of distribution and finally at the end-consumer’s smart refrigerator located in Warsaw, Poland. In order to activate this scenario, there is a need for digital infrastructure transversing the European continent from West to East. The more data readout points are collected at various stages of a product’s journey, the more information is created, and the higher its ultimate value. Yet, the realisation of such an infrastructure might seem technically complex and costly at first sight.

Indeed, it would be difficult to apply the IoT to wines, for instance, if the cost of digitisation and data collection is too high. If the IoT is to be applied to solving a problem, there is a trade-off between the added value or saved cost, and the cost to digitalise an object and the information about it. Is it fresh will provide a turnkey IoT solution that solves the dilemma for the customer. Through the optimisation of readout technology and smart data management, the initial investment costs are kept low. Coupled with the low-cost of freshtags, the entire solution starts bringing benefits quickly and ensures a short return on investment.

Connectivity: the academic vision

In his recent books, the leading American economist and author Jeremy Rifkin suggests that there is a paradigm shift on a revolutionary scale, triggered by the Internet of Things and the evolution of digital technology in the past decades. He points out the informatisation of everything (the ‘Third Industrial Revolution’) and predicts a prosperous future based on the IoT (‘The zero marginal cost society’). The IoT and digitalisation will become cornerstones of the industrial revolution for everything where the waste minimisation of limited commodities and resources becomes essential.

Is it fresh is right on top of the big wave of great innovation and it is devoted to making its technology an everyday reality. At last, we can help to solve the misery of the ‘forgotten yogurt’ in everyone’s fridge. So, imagine a future where your yogurt reminds you to be consumed and not end up like its analogue ancestors.

Jan Schnitker

Is it fresh GmbH

Dennewartstr. 25

52068 Aachen

Germany

+49 172 890 9982

info@is-it-fresh.com

http://www.is-it-fresh.com