The Midex Crescent Lake Lithium Project is located in Northwestern Ontario, an area gaining international recognition and popularity for hosting exceptional spodumene-bearing pegmatites.

As global policy makers advance towards meeting climate targets, most of the world remains on a lithium learning curve. An understanding of the fundamentals of lithium goes a long way in identifying projects with high discovery potential, and strong economics.

Lithium is found in a variety of minerals, including spodumene, petalite, lepidolite, and amblygonite. These minerals are found in pegmatite deposits, which are igneous rocks formed from the crystallisation of magma. Lithium is also found in brines, which are concentrated salt solutions.

Midex Resources Ltd. (Midex) has taken a deliberate approach of aggregating projects in Ontario, Canada. Midex’s understanding of Ontario’s geology and how it relates to regional controls on hard rock lithium deposits has informed their acquisition of highly prospective lithium assets in districts known to host large tonnage spodumene deposits.

Two main types of lithium

Once the spodumene mineral has been created through processing at the mine site, the next step is converting it into lithium chemicals. Lithium carbonate (Li2CO3) is the most common type of lithium compound. It is used in various applications, including ceramics, glassmaking, and, more recently, battery manufacturing. Lithium hydroxide (LiOH) is the precursor to lithium batteries.

Lithium chemicals can also be classified by their purity. High-purity lithium compounds are typically used in battery manufacturing, while lower-purity compounds may be used in other applications, such as ceramics and glassmaking.

Spodumene deposits and subsequent concentrates have the advantage of being able to provide feed to both lithium carbonate and lithium hydroxide plants. Lithium brine deposits are generally only used to produce lithium carbonate.

Why focused assets

Early on, Midex noticed the emerging trend of a backwards integration of the supply chain. This important signal guided Midex to concentrate on deposit types that would be the most attractive option for battery manufacturers.

Spodumene and petalite are both lithium-bearing minerals that are used in a variety of applications. However, spodumene deposits have several advantages over petalite, including:

- Lower mining costs: Spodumene is typically found in larger and more concentrated deposits than petalite, which makes it less expensive to mine;

- Higher lithium yields: Spodumene typically contains higher concentrations of lithium than petalite, which results in reduced processing costs as spodumene ore can more often produce a higher-grade lithium concentrate;

- Processability: Spodumene is simpler to process than petalite. This is because spodumene is a relatively soft mineral that is easily crushed and ground. It is also relatively soluble in sulfuric acid, which is the main chemical used to extract lithium from spodumene; and

- Versatility: Besides the above advantages, spodumene is also more versatile than petalite. Spodumene can be used to produce both lithium carbonate and lithium hydroxide, while petalite can only be used to produce lithium carbonate. This makes spodumene a more attractive option for battery manufacturers, who need both lithium carbonate and lithium hydroxide to produce lithium-ion batteries.

In addition to focusing on the potential of spodumene deposits, Midex has approached the acquisition of mining tenure with a business lens, concentrating acquisitions on properties that are located close to established infrastructure and supply chains, that are on strike of advanced staged projects that promote the acceleration of new discoveries; all to enhance future project economics.

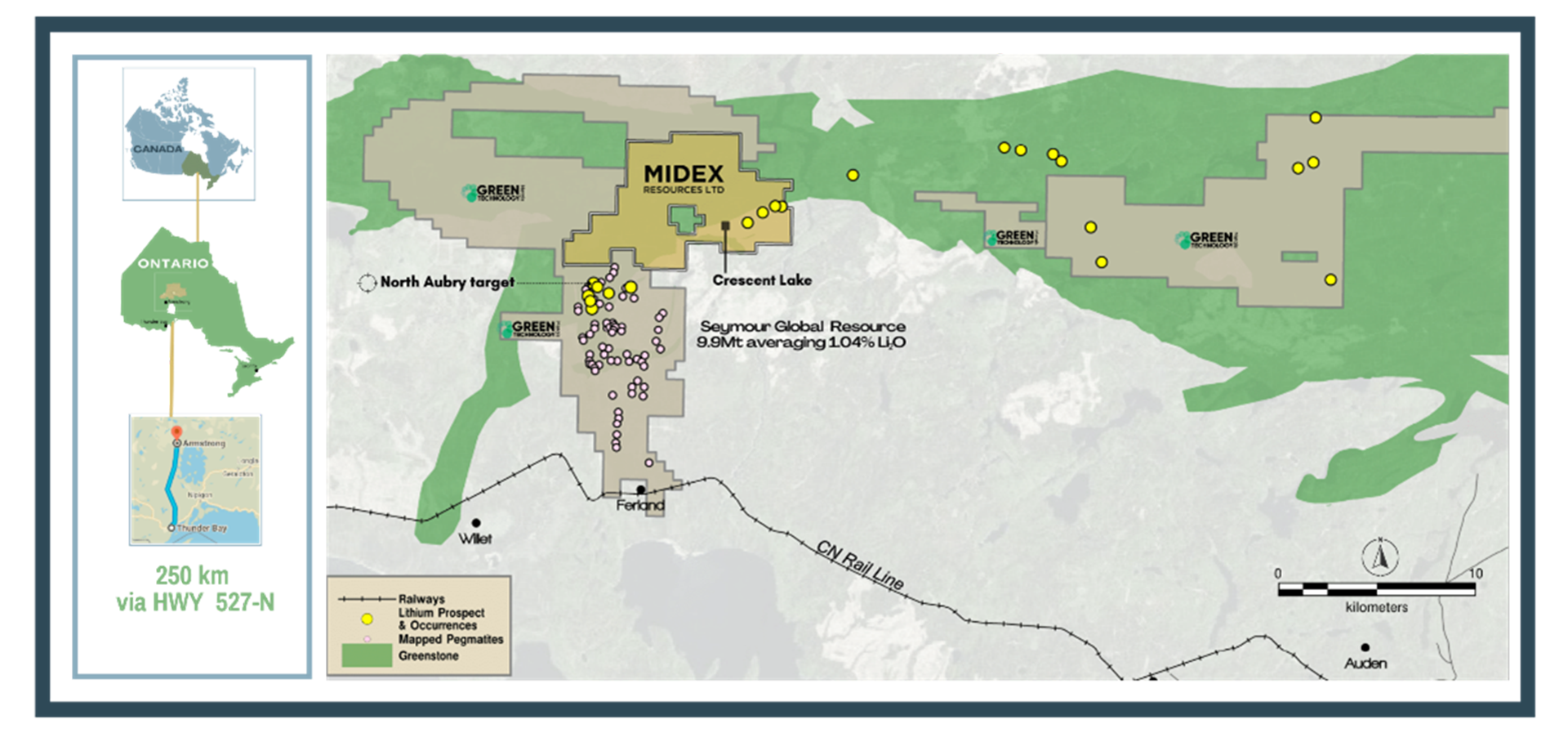

Midex’s flagship Crescent Lake Project is a prime example; located adjacent to Green Technology Metals ‘GT Metals’ (ASX: GT1) flagship Seymour Project. GT Metals recently announced their plans for a central spodumene processing facility on their Seymour Project, which is located directly adjacent to Midex’s Crescent Lake project, and less than ten kilometres from four of Midex’s spodumene pegmatite occurrences. GT Metals is also undertaking a Preliminary Economic Assessment on a lithium chemical conversion facility in Thunder Bay Ontario.

Midex controls nearly 40,000 hectares of lithium-focused mining claims that sit directly on key geological control structures that are proven to host spodumene-rich pegmatites. Advanced projects contiguous to Midex’s Berens and Crescent Lake projects continue to generate world class results. Most notably is the ‘GT Metals’ Seymour Lake Project.

Midex’s Allison Lake project is located in an active exploration area, approximately 40km from GT Metals Root Lithium Project, with a mineral resource of 12.6MT of 1.21% Li2O. Midex has completed surficial analysis or the area, informed by results from a recently flown LiDAR survey at Allison and has initiated prospecting and till sampling programmes.

Midex’s Onion Lake and Case Lake Projects are somewhat more grassroots in nature. The Case Lake Project is located in the Abitibi greenstone belt, adjacent to, and on strike with, Power Metals Case Lake Project.

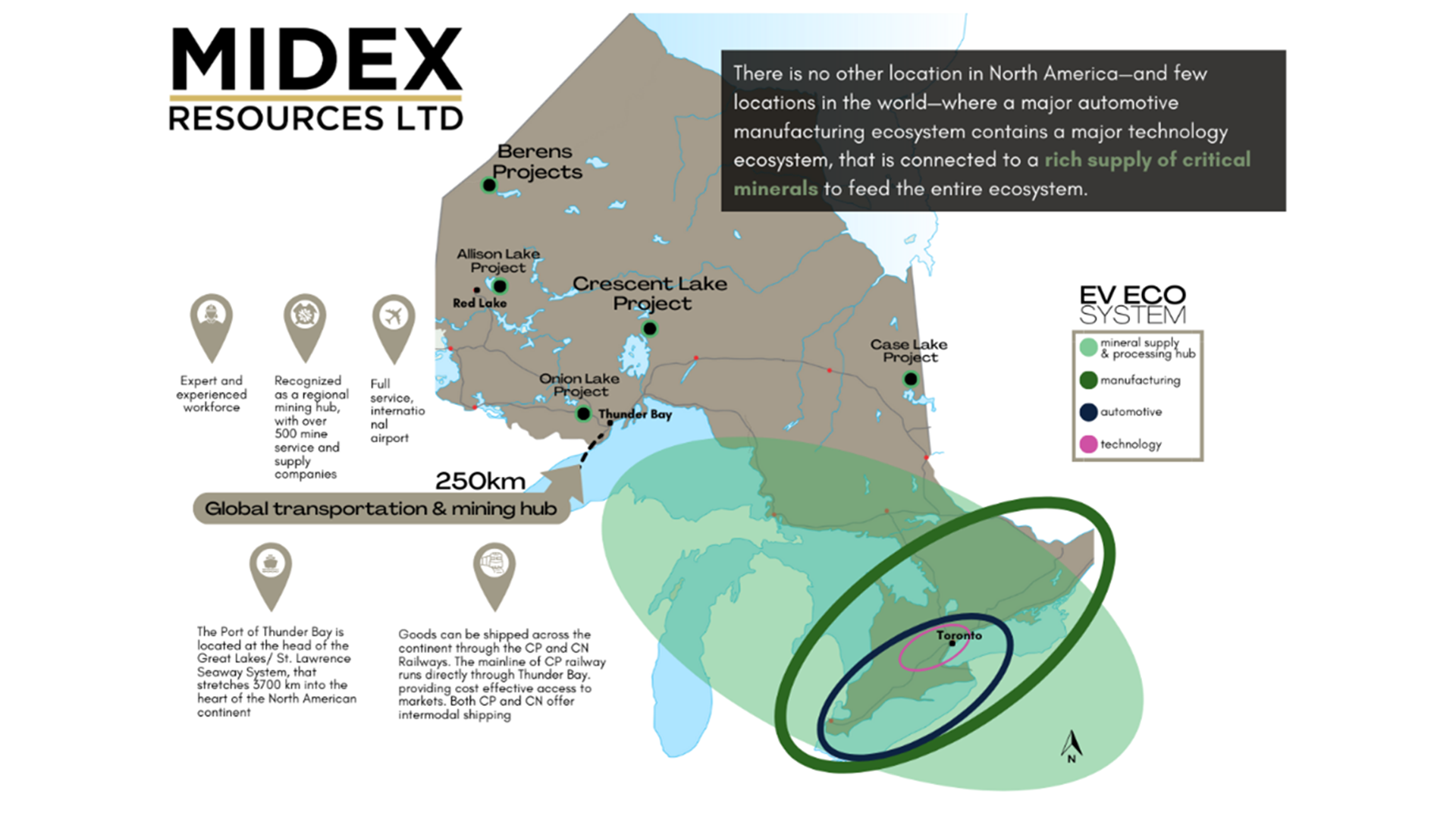

The Ontario EV ecosystem

Midex has assembled one of the largest, highest quality, royalty-free, lithium project portfolios in Ontario. Midex is strategically positioned to leverage the future advantages Ontario will have in terms of mineral concentrators, chemical conversion plants and transportation routes.

There is no other location in North America—and few locations in the world−where a major automotive manufacturing ecosystem contains a major technology ecosystem that is connected to a rich supply of raw materials to feed the entire ecosystem.

This dramatic shortening of transportation links represents a significant decrease in cost and the amount of CO2 emissions caused by the current long supply chains.

Of equal importance is Ontario’s stable and very low-emission electricity infrastructure. This nuclear and hydro-dominated grid can reliably power the lithium supply chain and provide increased security by having the entire supply chain located in an extremely stable jurisdiction.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.