Kuniko is spearheading efforts to establish a ‘mine-to-battery’ supply chain with Norway’s Ringerike district poised to become a critical minerals hub.

Norway, with the highest electric vehicle adoption rate globally and known as a test bed for green innovations, is now poised with the opportunity for its Ringerike region to transform into a pivotal hub for critical minerals essential for renewable energy and electric mobility. At the forefront of this development is Kuniko (ASX:KNI), whose vision is to establish a comprehensive ‘mine-to-battery’/ supply chain, aligning with Norway’s strategic goals for battery and critical minerals and the EU’s Critical Raw Material Act.

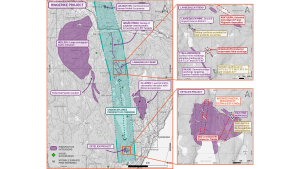

Unlocking the Ringerike nickel-copper-cobalt district scale potential

Located in southern Norway, Ringerike is a cornerstone of Kuniko’s strategy. The region, with historic nickel and copper mines, including the brownfield Ertelien and Langedalen mines, shows significant promise.

The Ertelien project, a key indicator of the region’s potential, boasts an inferred mineral resource of 23 million tonnes at 0.31% nickel equivalent. Recent drilling and assaying of unsampled historic drill core gaps aim to expand the resource base within 2024. Ground geophysics in unexplored areas of Ertelien have identified five new conductive horizons, suggesting the potential to add to the already identified 4.6 million tonnes of high-grade nickel and copper.

Beyond Ertelien, the broader Ringerike district has the appropriate geological conditions and known mineral occurrences to host multiple nickel-copper-cobalt deposits. Several mafic to ultramafic intrusions, some with notable extents, including the Holleia and Ullern intrusions, have been identified in Ringerike, representing compelling targets for unlocking the district’s full potential.

Advanced exploration and promising targets

Kuniko’s exploration methods target conduit-style magmatic Ni-Cu sulphides, similar to the Tier 1 Voisey’s Bay deposit in Canada and the Kevitsa mining operation in Finland. Interpretations suggest potential offsets of mineralised trends around the historic Langedalen mine, indicating they may be part of the same system.

Ground electromagnetic surveys have been completed at four targets along the trend of historic mine workings to identify conductive horizons that could indicate high-grade mineralisation. Extensive field mapping will assess district-scale prospectivity, identifying targets for follow-up ground-truthing and drilling.

Nickel, copper, and cobalt are critical for battery production. The Ringerike district is a pivotal asset in Kuniko’s portfolio, promising to become a significant player in the European battery value chain.

Innovating processing routes

Kuniko is conducting detailed mineralogical studies and flotation test work on Ertelien ore material to develop an efficient process flow sheet that optimizes nickel, copper, and cobalt recovery. These studies will inform the best routes for mineral processing, ensuring maximum recovery of these valuable metals.

Further, Kuniko is evaluating downstream processing routes, focusing on two primary methods: conventional pyrometallurgical processing and innovative hydrometallurgical processing.

While pyrometallurgical processing involves high-temperature smelting and higher energy consumption with CO2 emissions, hydrometallurgical processing uses aqueous chemistry for metal extraction, offering several advantages. It can be conducted on-site, reducing transportation needs and associated emissions, delivering higher recovery rates, and generating fewer sulphate waste byproducts.

Future prospects

Kuniko’s ongoing mineralogical studies and test work are crucial steps toward realising the mine-to-battery supply chain vision. By exploring both conventional and innovative processing routes, Kuniko is positioning itself to make informed decisions for sustainable and efficient project advancement.

Should hydrometallurgical tests prove successful, Kuniko could endeavour to produce battery end-products in Norway using modern, low-emission technologies. This would establish a strategically important European mine-to-battery material plant, producing battery chemical end-products such as nickel sulphate hexahydrate, copper sulphate, and cobalt heptahydrate.

Ringerike’s strategic location near Oslo, Norwegian battery gigafactories, and the deep-sea port of Drammen provides easy access to European markets. The project would maximise the use of Norway’s 98% renewable electric grid, maintaining a low carbon footprint. Leveraging Norwegian metallurgical competence and innovation, Kuniko would aim to deliver ethical, sustainable, and low-carbon battery metals through an environmentally friendly hydrometallurgical production facility.

Supported by long-term offtake agreements with global automaker Stellantis and integrated into the European battery value chain through Stellantis and Vulcan Energy ownership, Kuniko’s vision for Ringerike underscores Norway’s potential to lead in the sustainable production of critical minerals essential for the energy transition.

Pioneering sustainability in the energy transition

Kuniko’s vision for Ringerike underscores Norway’s potential to lead the sustainable production of critical minerals. Through detailed studies and innovative processing methods, Kuniko is paving the way for Norway to significantly contribute to a sustainable mine-to-battery supply chain. As part of its commitment, Kuniko targets net-zero carbon emissions and maintains leadership in Environmental, Social, and Governance (ESG) standards.

As the demand for electric vehicles and energy security grows amid geopolitical tensions, the strategic importance of regions like Ringerike cannot be overstated. Kuniko’s focused efforts in developing this area into a critical minerals hub bolster Norway’s position in the global market and contribute significantly to achieving sustainable and independent raw material and battery value chains.

Team experience

Kuniko’s leadership team brings extensive experience in mining, mineral processing, and sustainable project development, as well as expertise from the automotive and electro-mobility industries. This expertise strengthens Kuniko’s strategic vision for integrating critical minerals into the battery value chain, ensuring that Kuniko remains at the forefront of innovation and sustainability in the critical minerals sector.

Please note, this article will also appear in the 19th edition of our quarterly publication.