MIT researchers are developing a groundbreaking 1-megawatt motor that could propel commercial electric planes to new heights.

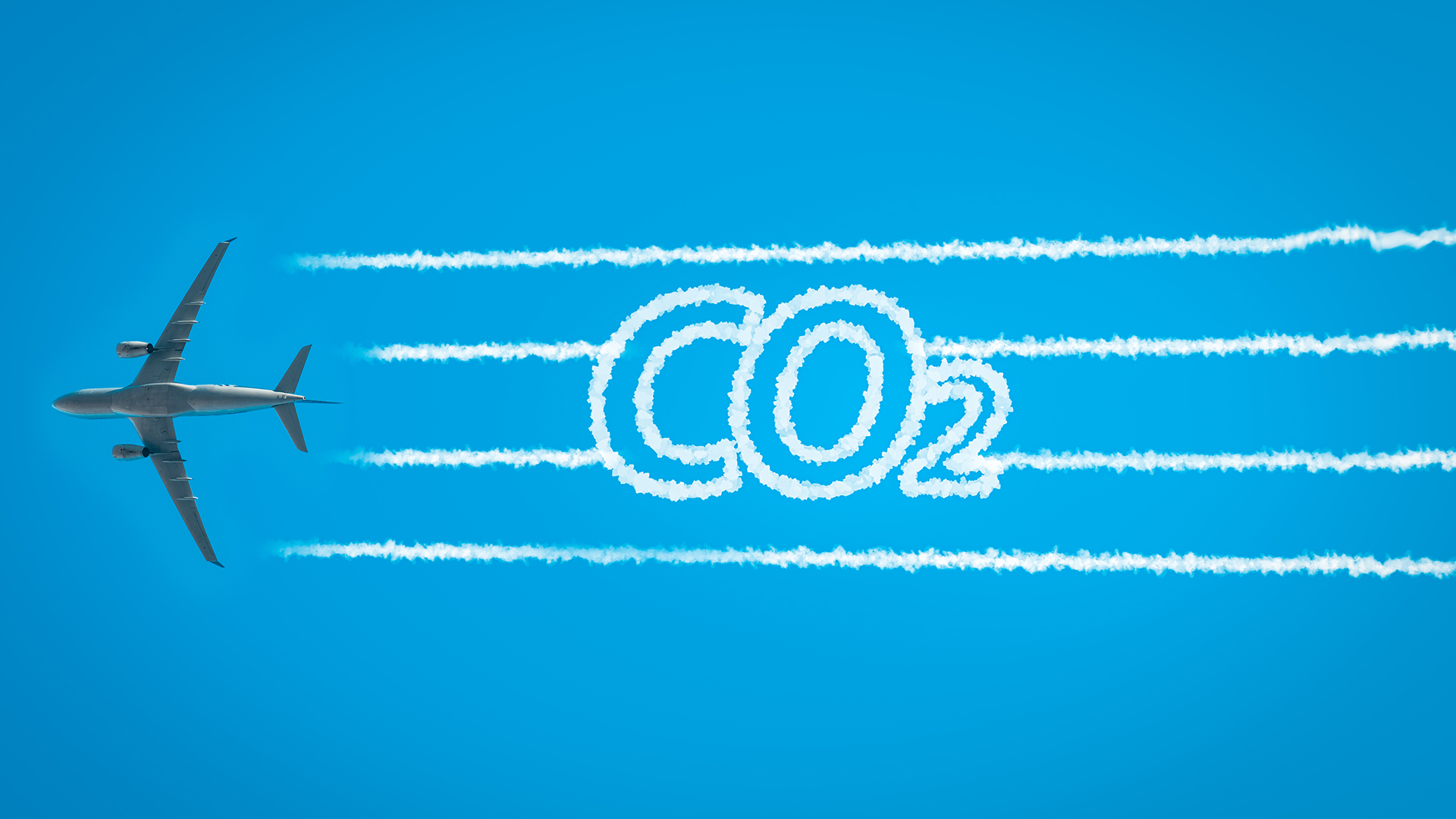

Electrifying the aviation sector will be critical to meeting climate goals – accounting for more than 2% of global energy-related CO2 emissions in 2021.

However, until now, engineers have only been able to develop small electric planes with motors that only produce hundreds of kilowatts of power. To see electric planes on a commercial scale, megawatt motors are essential.

Engineers at MIT are now creating a 1-megawatt motor that could propel electric planes to new heights. The researchers have already designed and tested the motor’s major components, with detailed computations showing the technology can generate one megawatt of power at a weight and size similar to current small aero-engines.

The team is confident the motor can be paired with a battery or fuel cell to power the plane’s propellers – or a traditional turbofan jet engine to run as a hybrid propulsion system.

Zoltan Spakovszky, the leader of the project and Director of the Gas Turbine Laboratory (GTL) at MIT, said: “No matter what we use as an energy carrier — batteries, hydrogen, ammonia, or sustainable aviation fuel — independent of all that, megawatt-class motors will be a key enabler for greening aviation.”

Challenges with electric planes

Various aerospace companies worldwide are striving to advance electrified propulsion and develop megawatt-scale motors that are powerful enough to propel commercial electric planes. This goal has proved incredibly challenging for the industry thus far.

Spakovszky explained: “There is no silver bullet to make this happen, and the devil is in the details. This is hard engineering in terms of co-optimising individual components and making them compatible while maximising overall performance.

“To do this means we have to push the boundaries in materials, manufacturing, thermal management, structures and rotor dynamics, and power electronics.”

Electric motors use electromagnetic force to generate motion – with the magnetic field typically produced through copper coils. Subsequently, a magnet positioned near the coils spins in the direction of the generated field to drive a fan or propeller.

However, the bigger the appliance or vehicle it needs to power, the larger the copper coils and the magnetic rotor needs to be, causing the machine to be heavier.

Additionally, the more electricity generated, the more components are required to keep the parts cool, taking up more space and weight. This is a major challenge for electric planes.

Spakovszky added: “Heavy stuff doesn’t go on aeroplanes. So we had to develop a compact, lightweight, and powerful architecture.”

How MIT developed a 1-megawatt motor

The MIT motor and power electronics are the size of an average suitcase and weigh less than an adult passenger.

The motor’s main components include:

- A high-speed rotor lined with a range of magnets with varying orientations of polarity;

- A compact low-loss stator that fits inside the rotor and contains an intricate array of copper windings;

- An advanced heat exchanger that keeps the components cool while transmitting the torque of the machine; and

- A distributed power electronics system made from 30 custom-built circuit boards.

“I believe this is the first truly co-optimised integrated design,” Spakovszky explained. “This means we did a very extensive design space exploration where all considerations, from thermal management to rotor dynamics, to power electronics and electrical machine architecture, were assessed in an integrated way to find out what is the best possible combination to get the required specific power at one megawatt.”

The electric motor is designed so that the distributed circuit boards are closely coupled with the electrical machine. This mitigates transmission loss and enables effective air cooling through the integrated heat exchanger.

Next stages of development

Each of the motor’s components has been individually built and tested to reduce risks and demonstrated to operate at conditions exceeding typical operational demands. They aim to assemble the first fully electric motor and begin testing this Autumn.

Once the team has shown the electric motor can work as a whole, it could be used to power regional aircraft and be utilised in conventional jet engines in hybrid-electric propulsion systems.

The technology could one day be scaled up to multi-megawatt motors capable of powering large commercial electric planes.