Lithium battery recycling is proving to be a crucial solution for reducing environmental impact and securing the future supply of critical battery metals.

A recent study by Stanford University highlights the significant advantages of recycling lithium-ion batteries compared to mining virgin metals, particularly in terms of greenhouse gas (GHG) emissions, water usage, and energy consumption.

The research found that lithium battery recycling emits less than half the GHGs of traditional mining processes and uses only a quarter of the water and energy. The benefits are even more pronounced for recycling defective scrap materials, which account for approximately 90% of the recycled supply.

This process results in just 19% of the GHG emissions, 12% of the water use, and 11% of the energy use compared to conventional mining and refinement methods.

Key sources of recyclable lithium batteries

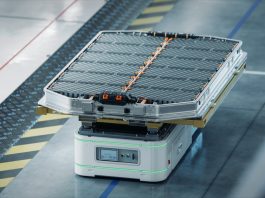

The primary sources of recyclable lithium batteries come from two main streams: defective scrap material from battery manufacturers and end-of-life batteries collected from businesses and consumers.

These sources provide essential metals such as lithium, nickel, cobalt, copper, manganese, and aluminium, all of which are vital for battery production.

Extracting these materials through recycling significantly reduces environmental degradation compared to traditional mining.

Additionally, the reduced energy requirements translate into lower levels of air pollutants, including soot and sulfur.

Location and energy mix

The environmental benefits of lithium battery recycling depend heavily on where the recycling facilities are located and the energy sources they rely on.

Regions that generate electricity primarily from fossil fuels, such as coal, experience a diminished climate advantage. On the other hand, areas with cleaner energy sources, such as hydropower, geothermal, and solar, provide an even more environmentally friendly recycling process.

A key case study comes from Redwood Materials in Nevada, North America’s largest industrial-scale lithium-ion battery recycling facility.

The company benefits from the relatively clean energy mix in the western US, helping to minimise its environmental footprint.

The role of transportation in battery recycling

Another critical factor influencing the sustainability of lithium battery recycling is transportation. Mining and refining critical battery metals often require extensive global transport.

For instance, about 80% of the world’s cobalt supply originates from the Democratic Republic of the Congo, with 75% of it then transported to China for further processing.

Similarly, lithium is primarily mined in Australia and Chile before making its way to China for refinement.

In contrast, recycling lithium-ion batteries requires much shorter transport distances. Research estimates that conventional mining and refining involve an average transport distance of 35,000 miles (57,000 kilometres), equivalent to circling the globe 1.5 times.

Meanwhile, collecting and transporting used batteries to a recycling facility in California would cover only about 140 miles (225 kilometres). This massive reduction in transport distances further enhances the sustainability of lithium battery recycling.

Technological advancements in battery recycling

While lithium battery recycling is still an emerging industry, innovative technologies are improving efficiency and sustainability. Conventional pyrometallurgical processes require extremely high temperatures, making them energy-intensive.

However, Redwood Materials has developed a patented technique called “reductive calcination,” which operates at lower temperatures, eliminates fossil fuel use, and increases lithium recovery rates.

Similar innovations are emerging in laboratories worldwide, refining recycling methods to make them more sustainable. These advancements, coupled with strategic facility placement, can further enhance the environmental benefits of lithium battery recycling.

The urgent need for industrial-scale recycling

Despite its benefits, lithium battery recycling is not expanding fast enough to meet the growing demand for battery materials.

Experts predict that global reserves of new cobalt, nickel, and lithium could become critically low within the next decade. While lower-grade minerals may still be mined, this approach is unsustainable in the long run.

Currently, the US recycles about 50% of available lithium-ion batteries. By comparison, lead-acid batteries, commonly used in vehicles, have achieved a 99% recycling rate for decades.

Given that used lithium-ion batteries contain materials with significantly higher economic value, increasing recycling rates presents a significant opportunity for economic and environmental sustainability.

Lithium battery recycling offers a viable and sustainable alternative to traditional mining, reducing environmental impact, securing critical metal supplies, and cutting down on global transportation emissions.

As technology advances and recycling infrastructure expands, the industry has the potential to become a cornerstone of the clean energy transition.