Float Europe (Float Marine Technologies Europe Limited) provides project development services including research, design, and development of marine technology products specialising in very large floating platforms.

Let’s begin this article with a question: ‘Is the shortest distance between two points always a straight line?’ In order to answer this, imagine an astronaut in her accelerating spaceship cabin; and imagine her pointing a laser horizontally across the cabin. As a result, the upward motion of the spacecraft would result in the path of the laser appearing to curve very slightly downwards as it crosses the cabin. We know that light always takes the shortest path between two points, which we usually think of as a straight line. However, a straight line is only the shortest distance between two points on a flat surface.

On a curved surface, the shortest distance between two points is actually a curve, technically known as a ‘geodesic’, which we can perhaps visualise when we think, for example, of a plane flying the shortest route between London and New York which follows a ‘great circle’ path over Newfoundland rather than what appears to be a more direct straight line on a flat map.

Another question we should ask here is: ‘when is a straight line not the shortest distance between two points?’ The Pythagorean theorem only works on two-dimensional surfaces like football fields; mathematicians refer to such surfaces as Euclidean geometry. The theorem fails for non-Euclidean geometries, such as spheres and more complex geometries like saddles. Indeed, all the rules you learned in school, like parallel lines staying parallel, only refer to Euclidean geometry. In the non-Euclidean universe, parallel lines may diverge or converge.

The EU factual situation

In 2013, the European Commission published a memo explaining that European ports are crucial for the EU transport sector and Europe’s competitiveness, as well as having a huge potential for both job creation and investment.

Moreover, the memo also explained that Europe’s ports are the gateways to the European continent. This is primarily because 74% of extra-EU goods are shipped through ports; and it is equally important for intra-European trade as 37% of intra-EU freight traffic passes by ports yearly. Alongside this, port activities contribute directly to employment, inward investment and GDP growth.

However, at the same time, Europe’s ports do still face numerous major challenges. Firstly, by 2050, there is a high amount of predicated growth expected. For example, it is anticipated that there will be 50% growth in cargo handling by 2030, increasing to 80% by 2050. More specifically, in 2016 108 million TEUs (20-foot equivalent units) were recorded. By 2030 this is anticipated to increase to 162 million, with a total of 292 million TEUs projected for 2050.

Challenges faced by European ports

Another challenge currently faced by ports in Europe is that there is a structural performance gap in the efficiency of European ports. For example, currently out of the 329 existing EU ports, 83 of these require upgrades. As a result, the following costs have been estimated: by 2020, it is anticipated that upgrades will cost around €500bn, increasing to €1.5 trillion by 2030 and approximately €3.6tn by 2050.

Another challenge relates to the changing nature of shipping. For instance, there is a constant pressure for EU ports to adapt to the changing needs of the industry. As a result, EU Member States could reinstate short sea shipping vessels and seafarer crews for each of their port facilities. Alongside this, the EU population is estimated to increase from 500 million in 2017 to 739 million by 2030.

Furthermore, it should also be mentioned that there is a significant need for more efficient ports. Thus, there have been numerous different proposals of new, transparent and open procedures. Continually, at the same time, it should be noted that ports require efficient delivery and shipping of their containers; while recognising the need for saving voyage time and reducing CO2 pollution. Finally, European ports still face the challenge of the need for better connection capabilities and an improved framework for investment.

Float Marine Technologies Europe Limited: responding to these problems

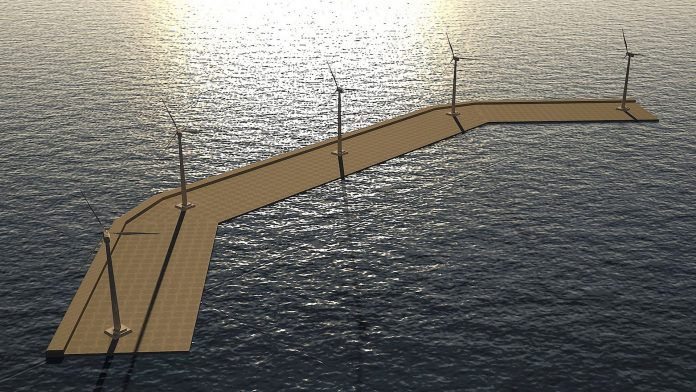

Using innovative means, containers delivered directly to a strategically positioned offshore deep sea shipping platform – the Float Incorporated Security Port – would provide direct service to each EU Member State via short sea shipping vessel use, which results in a positive impact in that all Member States can avoid EU cross-road transshipment; thereby reducing road traffic and CO2 emissions, as well as decreasing delivery times and costs incurred by each client.

Moreover, EU short sea shipping (SSS) vessels with capacities of 4,000 TEU, of which more than 1,100 are estimated to be currently idle, could be reactivated and manned by seafarers – 10 per vessel – to directly transship containers to their Member State destination. As an example, SSS vessel sailing time from the Netherlands or Portugal to farthest extremities of the ‘Atlantic Arc’ zone is estimated at 50 hours.

Ultra large container ships (ULCS) could reduce their voyage times by four to six days, resulting in reduction of ULCS operations costs. ULCS vessels which currently make multiple port calls within the ‘Atlantic Arc’ zone would avoid the necessity of doing so. Additionally, the reduction of CO2 emissions via road transshipment and potential pollution of the English Channel are enhanced by the positioning of the Float Inc. Security Port offshore, for instance from Mizen Head, Ireland.

Furthermore, there is an advantage of combination generally for both the ‘Atlantic Arc’ and Mediterranean Sea zones. Once fully certified and operational, it would become Europe’s first offshore floating platform hub port with an electricity baseload powered by LNG, and configured as an automated container-handling port hub serving the European ‘Atlantic Arc’ coastline ports, capable of automated reception, weighing, and 100% inspection of all inbound and outbound TEUs, thereby increasing the EU’s security profile.

The economic advantages of the EU-Atlantic Arc automated container-handling port hub are as follows: the Atlantic Arc Float Inc. security port hub would be the EU’s central transfer point with 100% TEU inspection, weighing and EU customs procedures. Moreover, Member State ports would not necessarily be required to perform costly port facility upgrades.

The advantages of wave energy explained

Wave energy holds a variety of advantages. For instance, the sale of electricity generated directly to platforms as well as vessels results in both a guaranteed market and reduced costs. Additionally, wave energy involves electricity which is balanced with the use of compressed air storage, as well as a baseload provided by LNG terminals. Another advantage is that the reduced cost of installation is a result of combined construction. For instance, the installation of the Rho-Cee WEC system incurs a platform-sharing cost; however, in the event of an extension of the offshore floating platform to accommodate the increasing amount of shipping volumes, the Rho-Cee WEC should also be extended to provide additional renewable energy generation that could be made available for use aboard the platform or for transmission ashore. Also, it should also be considered that the reduced operation and maintenance is a result of an ease of access.

Thinking outside the box on marine technology

Float Incorporated’s proposal for the Float Europe Security Port represents our response to multiple problems within the shipping sector both in the EU and worldwide. For example, the reduction of TEU vessels’ voyage times represents an automatic reduction of CO2 emissions compared to the levels produced today. In addition to this, the proposal also suggests an increase in the utilisation of short sea shipping vessels between the Float Inc. Security Port and Member States’ ports. It is also proposed that the employment of seafarers should be increased.

Another aspect of this proposal is that EU tractor/trailer transshipments of TEUs have been reduced by 29.4%, resulting in cost savings across multiple levels for ship owners, clients and ports. Employment has increased as a result of the demands for seafarers and port manpower. One effect of this is that both tractor/trailer and TEU transport are being utilised within national borders; therefore, transshipments across the EU have been reduced.

Why an offshore port hub system?

The primary question that we need to ask is why is it that an offshore port hub system is needed? Float Incorporated and Float Europe proposals respond to the EU goal for reduction of transshipment of TEUs across Europe by 30%. Coastal ports and canals or rivers can be utilised by appropriately designed TEU barges which carry between 4,000 and 4,500 TEUs per voyage. This can drastically reduce highway usage of tractor/trailer units and simultaneously reduce CO2 pollution.

Between now and 2030, shipping volumes are expected to rise by 50%. In terms of container traffic, these volumes are expected to rise even more. However, this can be accommodated without any costly hub port expansion expenses. It is important to note that at the same time, this responds to the immediate need to rapidly adapt to both new logistics, and economic requirements.

It also accommodates the increasing sizes of ULCS vessels, as well as removing any port congestion as a result of TEUs being diverted to Short Sea Shipping vessels – thus, avoiding costly road transshipments. For example, the short sea shipping vessels’ longest sailing time is at a maximum 50 hours (from the Float Inc. Security Port to Sines, Portugal or Amsterdam).

Float Incorporated: Potential Energy System (PES)

A Potential Energy Storage (PES) system avoids the principal objection to renewable energy sources. It is uniquely capable of storing substantial amounts of renewable energy as compressed air within the supporting PSP structure. No additional equipment need be supplied to exploit the PSP’s energy storage capability. The PES System uses the air handling equipment, ducting and valving of the PSP’s variable air buoyancy system.

Developed with USA DARPA and ONR support and proved in model scale, the PSP achieves its at-sea motion stability and structural loads mitigation by decoupling the ‘hull’ from ocean wave pressures through the partial use of mobile air buoyancy. Float Inc PSP technology chosen for inclusion in the USA Department of Defense’s Mobile Offshore Base research programme.

It is also stable with variable deck load capabilities, offering at-sea motion stability and structural loads mitigation by decoupling the ‘hull’ from ocean wave pressures using air buoyancy, which is both compressible and mobile within the PSP platform cylinders. The wave attenuation properties involve tank testing of incident wave heights of up to 20m. It was found that there is a range of transmitted wave reduction of 50% to 94%.

The PSP cylinders are assembled into modules, each one made up of 25 cylinders. The modules are assembled into PSP platform configuration. The construction consists of pre-stressed reinforced concrete, with an expected lifetime that exceeds 70 years. There is also no dry docking for maintenance, hence there is no out-of-service time. Moreover, it is easily extended (as required), without any interruption of the existing platform. Pre-tank testing is required to respond to candidate site specifics resulting in the design for construction.

The construction is also controlled and monitored to respect its design; and the component is also towed (although not assembled) to the required site. Assembly of PSP modules occur at sea; however the sea state environment must be at the maximum of three for assembly. Candidate site specifics will determine the anchorage systems, but in general a catenary anchorage system is preferred.

An innovative wave energy converter: Rho-Cee Wave Energy Converter (WEC)

The Rho-Chee is an Impedance-Matching, Oscillating Water Column (IM-OWC) system. It is intended to be solidly supported by a PSP. Constructed in reinforced concrete, all the equipment is in air – none of it is in water. The Rho-Chee is accessible for maintenance by personnel on foot; and it may be combined with large offshore wind turbines and submerged ocean current turbines. In combination with the PSP, it can provide highly effective floating breakwater with leeward calm water vessel berthing zone.

Float Incorporated Pneumatically Stabilized Platform – seagoing properties and strengths

It should be noted that simplicity in design does not necessarily require expensive specialised construction facilities. These can in fact be constructed near the installation point or can be towed and assembled at installation point. Furthermore, there is no need to move major mechanical components resulting in longevity of utilisation (estimated to be 70 plus years), with reduced maintenance requirements.

Potential applications can include breakwater, marina, port, housing, industry and energy centres. The PSP floating platform provides a ‘calm water zone’ for cruise liners, yachts, and small crafts berthing. The PSP design is modular, permitting future expansion (it has a polyvalent superstructure use), and additionally, the PSP floating platform can be repositioned and reconfigured to accommodate changing future requirements.

Configuration for each PSP application is ‘tuned’ specifically for that installation. Alongside this, it is also environmentally friendly as it promotes and maintains both fauna and flora growth. It has been thoroughly tank tested with positive results, superior to what was initially expected. Float Incorporated’s positive tank test results were confirmed and validated in subsequent tank tests performed by DARPA and then ONR.

Franklin Martin

FLOAT EUROPE

+33 493 378 543