The Met4Tech project is bringing together leading UK academics for research that will enable an alternative circular economy to power the green energy transition.

Met4Tech brings together leading researchers to maximise opportunities around the provision of technology metals from primary and secondary sources, and lead materials stewardship. The organisation is creating a National Technology Metals Circular Economy Roadmap to accelerate the UK towards a circular economy.

In order to achieve a net zero carbon economy, most countries have ramped up the production of electric vehicles (EVs), as one of the key policy measures that will contribute to cleaner energy. In order to power EVs, a supply of critical metals, such as rare earth elements (REEs), are used in magnets for the motors and powertrain, and metals such as cobalt and lithium are needed to manufacture the EV batteries. These metals and many others are also used in batteries within smartphones, laptops, and consumer products, meaning they are a critical component of our everyday lives. Due to this, a stable circular supply chain of technology metals will need to be established to ensure supply levels can meet the anticipated demand for EV battery production rates, as well as other critically important applications.

In order to meet this demand, the UK’s Critical Mineral Strategy was announced earlier this year. Through this strategy, the UK will collaborate with international partners to accelerate the growth of our domestic supply of critical minerals.

Here, in conversation with The Innovation Platform, several of Met4Tech’s developers – Carol Pettit, Frances Wall, Evi Petavratzi, Aleksandra Čavoški, and Robert Lee – highlight the project’s objectives and how these align with the UK Government’s plans to improve our critical metals supply.

What is the current landscape for technology metals in the UK? What needs to change?

Like most other industrialised countries, the UK is keen not only to achieve its 2050 climate change targets, but also to take part in the manufacturing of low-carbon vehicles and renewable energy technologies. For the UK to take advantage of a £2.7bn opportunity to supply battery materials and add 60,000 jobs in battery and car manufacturing, it must have secure and responsibly sourced supplies of technology metals. The value and volume of these technology metal flows is as high as for industrial metals; however, their functionality is sought after and essential for delivery of high-tech applications. Without metals such as REEs, cobalt, tungsten, tin, and lithium, the greater value activities cannot take place.

The same applies to almost all new digital and clean technologies, as technology metals are today’s key enablers for the green economy and energy transition. Many technology metals are labelled as ‘critical’ in the UK, meaning those at risk of supply disruption. They also often have low recycling rates and poorly understood flows despite the rapidly increasing demand.

What is Met4Tech and how does it work to accelerate a domestic supply chain for technology metals within the UK?

The UK’s new Circular Economy Centre for Technology Metals (Met4Tech) will help the country to maximise the opportunity by obtaining technology metals from secondary and primary and lead materials stewardship, to maintain these metals in use at high value. Met4Tech brings together leading UK academics, as well as several partners from across the value chain, to take part in interdisciplinary research and policy interventions. The overall objective is to create a roadmap for an alternative tech metals circular economy (CE) system involving all key actors, agent-based modelling, strategic business models, technology forecasts, design options, new raw materials practices, regulatory requirements, and societal preferences.

What has 2022 looked like for Met4Tech? What are the most standout achievements from the projects you have been involved with?

The first key objective of the Met4Tech project is the UK Technology Metals Observatory, hosted at British Geological Survey (BGS), which describes the stocks, flows, and current practices – including state-of-the-art CE best practice for technology metals – as well as laying the foundation for monitoring and tracking increases in CE-based revalorisation.

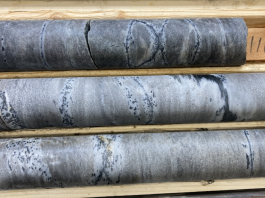

There is a detailed new case study that illustrates the CE principles approach to using novel geo-models. These models analyse the granite-related (lithium, tin, tungsten) mineralisation and related mine waste in Cornwall, which involves collaboration with mining companies and regional government partners. The research teams have been building on the previous Faraday Battery Challenge and Driving the Electric Revolution (grenDER) projects in the UK to initiate many new collaborations and technology studies for Met4Tech.

Efficiently recycling technology metals involves alternative approaches to the traditional shredding and pyrometallurgy/hydrometallurgy approach. Linking together partners with different waste streams and processing technologies is leading to more innovative recovery techniques and circular approaches. There is also much interest in our cross-cutting topics, including:

- Social science and responsible innovation;

- Governance and regulation;

- Environment and life cycle assessment; and

- The environmental, social, and governance (ESG) aspects for the technology metals supply and value chains.

The UK’s first Critical Minerals Strategy was announced earlier this year. Why is this so important and how will it impact the direction of your own work/how does it align with your current work?

The UK’s new Critical Minerals Strategy describes three overarching actions that align well with the research objectives of Met4Tech. The first action is to accelerate growth of the UK’s domestic capabilities, which is being illustrated by our technical and regulatory research in the Cornwall case study, as well as the whole value system approach of our technology metals CE roadmap.

The second action is to collaborate with international partners, which is already happening within the Met4Tech CE Centre, and our strategy is to develop more overseas collaborative links.

The third action is to enhance international markets to make them more responsive, transparent, and responsible, and the research from our ongoing Met4Tech case studies and research on responsible innovation will help inform continuous updates to the Critical Minerals Strategy. The formation and funding of a new Critical Minerals Intelligence Centre at the BGS will also be able to build directly on the virtual observatory research conducted by Met4Tech.

How important is international collaboration in accelerating the UK’s critical minerals supply chain?

The determination of ‘critical’ minerals for the UK, and other countries, depends on the national setting and considers the economic value and security of supply of these metals for several strategic applications. The global context for the production and supply chains is important, and international collaborations will be essential for securing the UK’s access to the critical minerals and technology metals.

The overall aim of Met4Tech is to co-create a roadmap to a technology metals circular economy for the UK in an international setting. The Met4Tech project is mainly national and there are also strong links to international groups. The researchers are looking closely at regional case studies, and holding international regulatory roundtable events to discuss recent developments worldwide. We are also looking to form international collaborations with several groups and centres.

Carol Pettit and Frances Wall

Camborne School of Mines

University of Exeter

https://csm.exeter.ac.uk/

Evi Petavratzi

British Geological Survey

https://www.bgs.ac.uk/

Aleksandra Čavoški and Robert Lee

Birmingham Law School

University of Birmingham

https://met4tech.org/

https://twitter.com/Met4Tech

Please note, this article will also appear in the twelfth edition of our quarterly publication.