Evora University present their latest research which encompasses the design and development of new functional selective sorbents for the isolation/preconcentration of pesticide in olive oil samples.

Olive oil (OO) production plays a crucial role within the national economy of Mediterranean countries, including Portugal. To avoid possible losses at harvest or in production, several pesticides are applied to olive groves – namely organophosphorus and pyrethroids insecticides. To ensure consumer safety, the levels of pesticide residues in OO must be monitored with accurate methodologies. Previously, a tedious and laborious step of sample preparation was mandatory in order to pre-concentrate/isolate the target pesticide. Standard methods for this quantification are based on the chromatographic techniques ‘High Performance Liquid Chromatography’ (HPLC) and ‘Gas Chromatography’(GC), coupled to mass spectrometry (MS). The development of more sensitive, selective and automated techniques for pesticide testing in OO is highly warranted – our research group has been following a path in order to achieve this challenging goal.

Our works focus

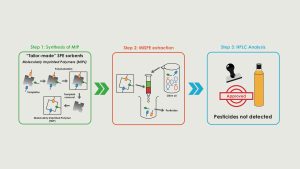

Aiming to circumvent the lack of selectivity of the most common commercial sorbents for solid phase extraction (SPE) used in the sample preparation step, our research group developed a new and selective approach based on the use of molecularly imprinted polymers (MIP) as SPE, and implemented an analytical workflow for the detection and quantification of pesticide residues in OO (see Fig. 1). MIPs are produced by molecular imprinting technology (MIT), which is a template-direct technique which allows for the design of polymeric materials with well-defined artificial generated recognition sites that are specifically engineered for a target analyte or class of analytes.

As depicted in Fig.1, the imprinting process (which is the first step) uses a template molecule and a functional monomer for co-polymerisation in the presence of a cross-linking agent, leading to three- dimensional polymer formation. After the removal of the imprinted molecules, the resulting MIP will contain specific cavities or imprints that are sterically and chemically complementary to the template molecule. Theoretically, if the system was designed properly, enabling the polymer to selectively “rebind” the imprint molecule and its analogues from a mixture. Since MIPs rely on affinity interactions and offer a higher degree of sample clean-up than that achieved using conventional type SPE sorbents, the selectivity is significantly improved. Subsequently, the interfering background can be reduced and much lower detection limits relative to other less selective sample preparation techniques are achieved using an MISPE approach (referred to as step 2).

A step forward in MISPE technology – the development of ‘smart’ MIP-based sorbents

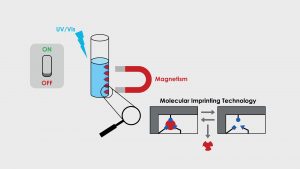

Aiming to achieve an easier separation from the matrix and a controllable uptake/release of pesticide residues, advanced functional MIP-based materials have been designed and produced in our lab and further introduced in the sample preparation step during the analysis of pesticide residues in OO. Since these materials are “stimuli- responsive” (known as “smart-MIPs”), a “on-off” switchable tool for OO sample preparation that merges molecularly imprinting technology with stimuli-responsive blocks- namely magnetic and photonic stimulus, has also been successfully implemented with both high selectivity and recovery rates (see Fig. 2).

Moreover, the development of “smart”- MIPs with a dual character- photo- and magnetic-, enables fast and simple separation from the matrix, while the photoresponsiveness property offered simple template elution by using UV–Vis irradiation, proving their suitability for trace pesticide analysis in a complex sample, as OO with low detection limits.

Exploring a way to bring automation into pesticide trace analysis

Our research group is studying the possibility of developing a selective, reliable and robust sensor technology named as MIP2Sensors, encompassing MIPs as recognition elements with an additional “light-up” signaling of the target pesticide presence. Within the development of this sensing tool, it is expected enhancements in selectivity, stability, robustness, portability and will also be easy handling. Thus, an “on-site” monitoring of pesticide residues levels in a highly complex matrix will be achieved with remarkable advantages.

Raquel Garcia

Maria João Cabrita

MED – Mediterranean Institute for Agriculture, Environment and Development

Departamento de Fitotecnia

Escola de Ciências e Tecnologia Universidade de Évora

+351 266 760800

raquelg@uevora.pt

pesticides in olive oilmjbc@uevora.pt

Please note, this article will also appear in the first edition of our new quarterly publication. Subscribe to our updates for free here.