Chris Garratt of Proventia Oy details the intricacies of EV battery testing and how their modular battery testing units can adapt to future needs.

In electric vehicles, what most people would think of as the ‘battery’ is called a pack. As the name suggests, the pack is built up from several smaller units called modules. These modules, in turn, are made up of individual cells. The cells are made by a few major suppliers, using various technologies and chemistries. Extensive testing is done on these cells by the companies that make them.

The end customer or OEM often assembles the modules and packs, and the size and shape will be determined by the application and space available. This means that each module and pack need to be validated to ensure it performs as expected in the environment it will be used in.

Several aspects need to be tested during the development phase of the modules and packs. Typically, the Battery Management System (BMS) is tested separately using Hardware-in-the-Loop principles, and a reasonably mature BMS is used for physical testing. For physical testing, the aspects outlined below need to be tested.

Real-world performance simulations

Like any engine that goes into a production vehicle, electric powertrains need to be tested on real-world drive cycles. This will ultimately be done as a complete vehicle test on the road, including the motor and inverter. At earlier stages, the real-world performance can be tested using a battery cycler, which can simulate the load that the vehicle’s powertrain would require (the amount of energy drawn by the vehicle to power it down the road). Electric and hybrid vehicles also re-charge the battery under braking, which can also be simulated.

Charging and discharging performance

One of the most contentious issues around electric vehicles is charging, so clearly, this needs to be thoroughly tested. Battery cyclers can simulate a variety of chargers, and it is possible to bring in commercially available chargers to test pack charging.

Effects of temperature and humidity

The environment that vehicles (and their components) need to work in is massively varied. Even in mainland Europe, temperatures can reach over 40°C, and temperatures can rise much higher inside the vehicle. In Northern Europe, Russia, and North America, temperatures can drop well below -20°C, and in Asia, humidity can reach above 90%. There are different standards depending on which markets the battery or vehicle manufacturers want to sell into.

What is required for battery testing?

A few vital bits of equipment are needed to perform the necessary tests. As described above, the most critical piece of equipment is the battery cycler, which can charge or discharge the pack and simulate the vehicle’s load. The most important aspects to consider for the cycler are the voltage and current profile it can deliver and the responsiveness of the cycler. The faster it can respond, the more accurately the simulated drive cycles can be recreated.

An automation and data acquisition system controls the simulation of the drive cycles and monitors the temperatures and communications to the pack under test. This is often split into a regular desktop PC and a real-time operating system for deterministic testing.

The Proventia solution

Testing prototype battery packs is a potentially risky business, requiring several safety precautions. Whenever carrying out thermal, electrical or mechanical testing of EV batteries, the risk of chemical leaks is of paramount importance. Add to that the risks involved when testing prototypes; a safe solution has to be employed.

Extensive testing and validation of the battery packs and modules ensure they perform as expected in the environment in which they will be used. Proventia has developed the standard in modular battery pack testing equipment. Proventia’s climatic EV battery testing chambers are designed for both module and complete battery pack requirements.

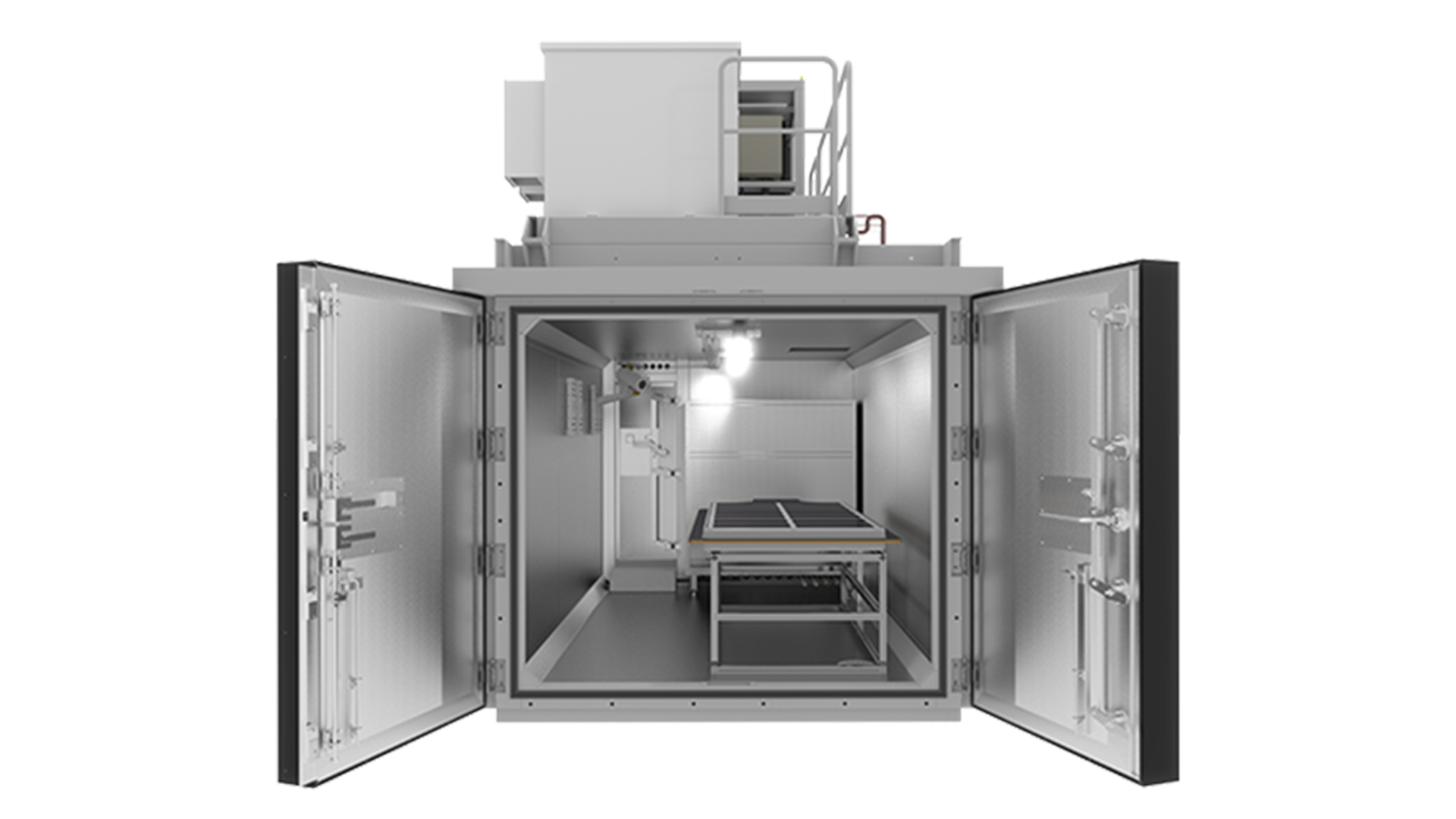

Overview of the climatic EV battery pack test chamber

Proventia’s climatic EV battery test cells enable real-world performance simulation, charging and discharging performance testing and the effects of temperature and humidity to be tested. The large climatic chamber can be located inside or outside a building and allows full vehicle packs between -40°C and 90°C, and 10% to 95% relative humidity, to be tested.

Proventia‘s battery test laboratories conform to the EU Machinery Directive and health and safety regulations, with plans to have a US-ready module by the end of 2022. The modular test cells and centres are fully equipped with modern safety features, including the customer’s preferred fire suppression and facility alarm systems.

A true turnkey solution

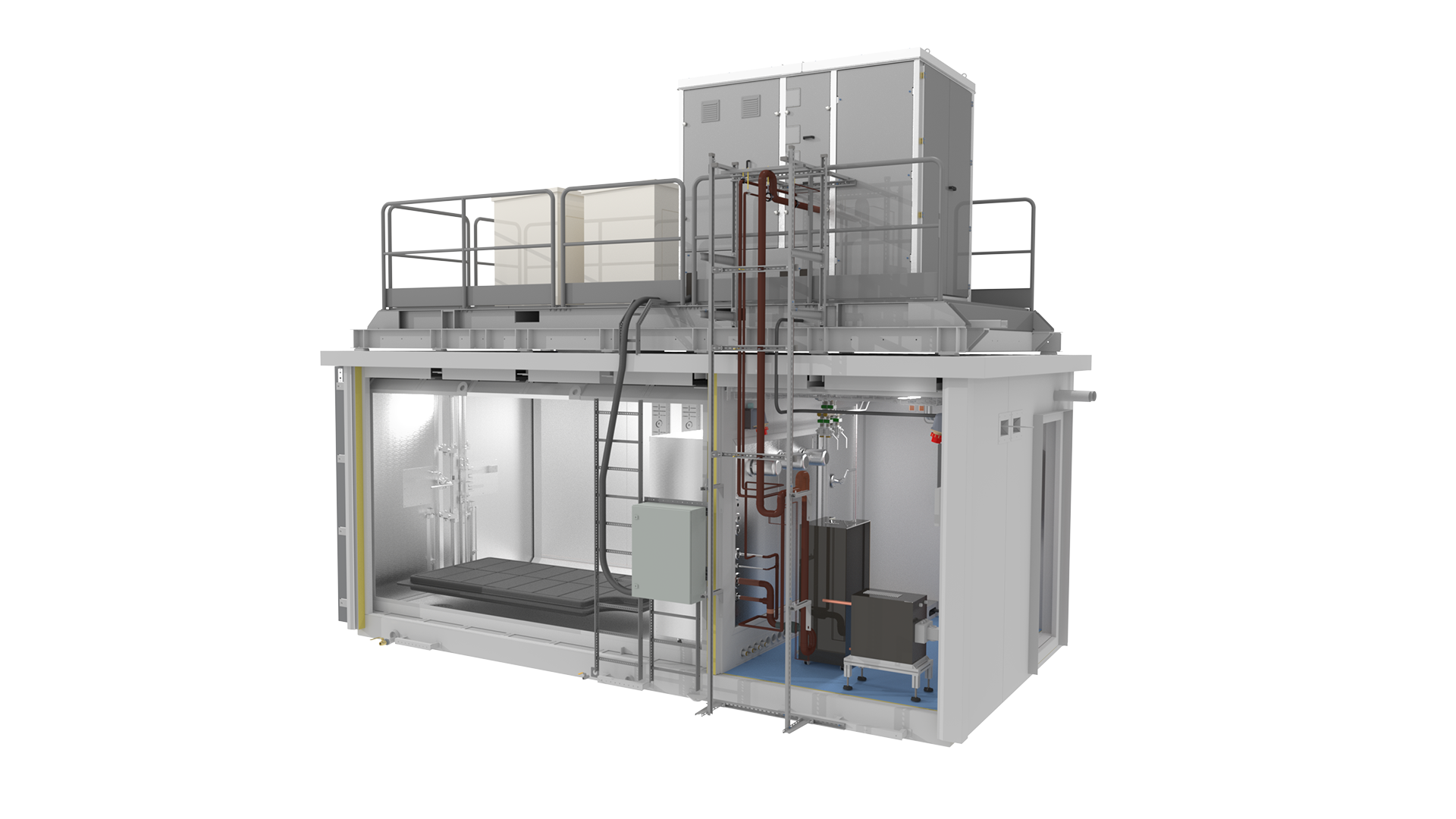

As a free integrator, Proventia can combine the high-performance test equipment of the market leaders with the customer’s preferred suppliers. Proventia will integrate the battery cycler, coolant conditioning, automation and data acquisition equipment, as well as any other test equipment needed.

The Proventia battery pack and module testing unit is a true turnkey solution, including the necessary safety, power, HVAC, plumbing and cabling infrastructure, and complete building management solutions for the test space.

Standard industrial battery test chambers

In addition to customer-specific designs of battery testing solutions, Proventia also offers standardised industrial test modules that fulfil all the industry requirements and are quick to deploy.

Specifications:

- Cycler capability: 1MW, with the ability for parallel connections between cyclers;

- Safety features: Access control, fire detection and suppression, gas detection, blast panels;

- Included equipment: Battery emulator, automation system, coolant conditioning, test cell infrastructure; and

- Optional equipment: Pack handling equipment.

Battery pack storage

Our lithium-ion battery pack and module storage units offer a factory-built, standard ‘plug and play’ type of modular unit specially designed to safely store EV battery packs and modules.

Our safe storage units are designed in accordance with the EU Machine Directive. They are structurally designed to keep the batteries stable, dry and clean to minimise the risk of injuries posed by the batteries themselves or by gases, liquids, vapours, or other substances produced or used by the batteries.

Our units are the safest possible, offering 100mm insulation, industrial sandwich panel (EI60 fire rating), fire detection and high-pressure water mist fire suppression system, gas detection (CO) system, fire-proof cable penetrations.

Building modular

In today’s fast-changing automotive industry, modular test cells are ideal for building new test capacity. Thanks to their flexible and scalable nature, the test facility built in a modular way remains transportable, scalable, and upgradable during the whole lifecycle. Proventia’s modular solutions are optimised according to performance, facility supplies, and, most importantly, customer needs and preferences. As a free integrator, Proventia can integrate the test stand dynamometers, inverters, simulators, test equipment and automation systems from any leading key component suppliers.

As the name suggests, a modular test cell or centre consists of ready-made modules that structurally and environmentally meet the high-performance standards of a testing facility. These are spacious cells with insulated walls and strong structural integrity. One module is often enough for a small test cell to contain all the required components. Multiple modules can be smartly combined for larger test facilities, including multi-axis testing or full vehicle testing to provide the required space. A modular test cell can be located indoors, where it can replace existing capacity or outdoors, creating an entirely new test centre that does not require significant construction work onsite.

Advantages of building modular

There are three significant advantages to building modular. The first and essential advantage is the overall project delivery speed. These modular test centres can typically be built and delivered in significantly shorter timelines than traditional block-built cells. A modular solution needs very little construction work onsite, so planning requirements are minimal. All that is required is a level concrete base, electricity and water supply; Proventia handles the rest. By building the test cells in modules, all the equipment can be installed in parallel with any minor onsite construction work.

The second advantage is portability. The test modules can be built to be almost entirely self-contained; therefore, they can be easily moved and relocated using standard lifting and transportation equipment. If testing needs change, the testing capacity can be moved to a new location — a valuable advantage in today’s fast-moving automotive industry. Portability also affects the scalability and cost-spread. Upgrades, expansions and changes in location can be made in stages, deploying test cells in accordance with the actual need.

The third advantage is safety. Modularity is advantageous in safety-critical applications, such as hydrogen fuel cell testing and battery testing. It can be beneficial to locate a test cell away from other buildings.

Proventia’s other solutions

As well as being a leader in automotive pack testing, Proventia has developed several other solutions for electric vehicle development, all using the modular approach. Notably, Proventia has recently delivered the new Intertek Electric Vehicle Testing Centre of Excellence, winning Automotive Testing Technology International’s Engine Test Facility of the Year. This facility comprises several state-of-the-art test cells, including a 27k RPM eMotor dynamometer and full vehicle 4-axis hub dyno, which can be split into two eAxle test cells delivered with Proventia’s patented modular approach.

Please note, this article will also appear in the ninth edition of our quarterly publication.