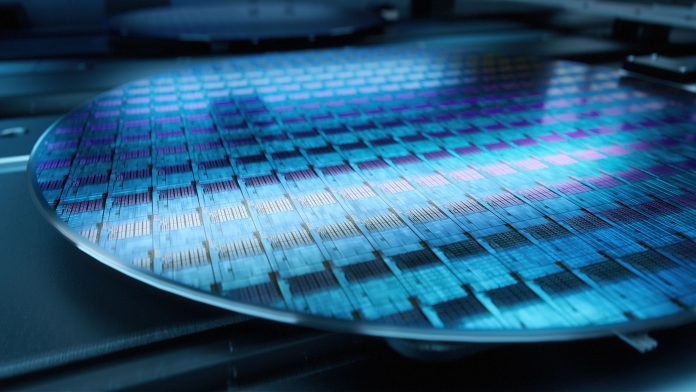

HPQ Silicon Inc. and PyroGenesis Canada Inc., have successfully poured silicon using the innovative PUREVAP™ Gen3 QRR technology, setting a new benchmark in sustainable and high-purity silicon production.

HPQ Silicon Inc., in collaboration with PyroGenesis Canada Inc., has achieved a pivotal breakthrough, successfully pouring silicon using its PUREVAP™ Gen3 QRR technology. This technological leap affirms the scalability and efficiency of HPQ’s production processes. It strategically positions the company to cater for the surging demand in the battery industry, propelling it towards a future where technology and sustainability coalesce seamlessly.

Silicon, a critical element in various industrial applications, especially in the burgeoning battery industry, is experiencing a radical transformation thanks to the innovative advancements spearheaded by HPQ Silicon Inc. and its strategic collaborator, PyroGenesis Canada Inc.

A pour symbolising more than success: A pioneering leap

The recently accomplished silicon pour, an integral component of HPQ Silicon’s PUREVAP™ Gen3 QRR testing, signifies more than a mere technical triumph. It represents a moment where meticulous engineering, innovative strategies, and sustainable visions amalgamate, paving the way towards a new horizon in silicon production.

HPQ Silicon’s approach has never been about just meeting industry standards but surpassing them, thereby presenting new benchmarks of quality and sustainability in silicon production. The company has successfully validated 100% of the project’s crucial milestones, including achieving an exceptional 99.5% Silicon purity (2N+) right from the onset and demonstrating the semi-continuous batch production capability of the reactor.

Redefining silicon production: The role of PUREVAP™ Gen3 QRR

Silicon production has historically been tethered to processes like the carbothermic process, which not only demands a hefty ratio of raw materials-to-silicon output but is also notoriously high in CO2 emissions. The PUREVAP™ Quartz Reduction Reactor (QRR) represents an avant-garde approach to silicon production, mitigating these challenges effectively.

- Scalability: With a 2,500x production scale-up from its Gen2 counterpart, the PUREVAP™ Gen3 QRR affirms the viability of scaling innovative silicon production without compromising purity or efficiency;

- Purity: Surpassing commercial thresholds, the technology has demonstrated the capacity to achieve 99.5% silicon purity, enabling the production of high-quality silicon that stands to revolutionise several industry applications; and

- Sustainability: By enabling the production of silicon using 25% less feedstock than conventional methods, HPQ is presenting a more sustainable, economically viable alternative in silicon production, with reduced raw material usage and minimised waste.

Advancing towards a sustainable future

With a pivotal role in realising the silicon pour and aiding in achieving the critical milestones, PyroGenesis Canada Inc. has been instrumental in advancing the Gen3 QRR technology. The accomplished pour not only signals technological prowess but also the fruitful collaboration between HPQ and PyroGenesis, merging expertise to navigate the future of sustainable silicon production.

Strategic alignment with the booming battery industry

As HPQ Silicon propels forward, the utilisation of its high-purity silicon in the battery industry is particularly noteworthy. The surge in demand for silicon anode materials, driven by its incorporation into lithium battery graphite anodes, brings HPQ’s technological advancements into a strategic position to cater to this growing demand. With forecasts indicating an upward trajectory in market demand for silicon, reaching potentially 300,000 tonnes by 2030, HPQ’s strategic positioning cannot be understated.

Moving forward

The strides taken by HPQ Silicon in its Gen3 QRR technology echo the paradigm shift essential in guiding the industry toward a sustainable future. It presents a narrative where innovation, sustainability, and strategic market orientation coalesce to navigate the path forward in the world of silicon production.

The recent achievements are not a destination but a significant marker on HPQ’s ongoing journey towards refining and revolutionising silicon production, thereby crafting a future where the technological and ecological coexist harmoniously.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.