The new battery recycling method can simplify current processes, which recycles elements by dissolving battery cathode with strong acids.

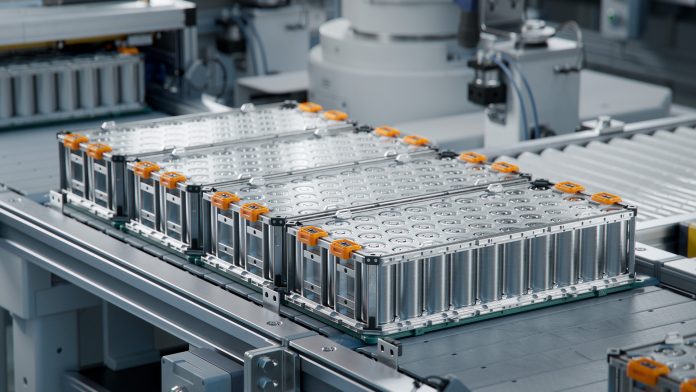

Developed by Professor Peter Slater, Professor Paul Anderson, and Dr Laura Driscoll from Birmingham’s School of Chemistry, the new battery recycling method focuses on recycling the highest value component of end-of-life electric car batteries – the battery cathode.

Organic acid, such as ascorbic acid, is used as a leaching agent. It has been tested on cathode material from a first generation Nissan Leaf battery cell that had powered 40,000 miles of driving.

The research, ‘Phase-selective recovery and regeneration of end-of-life electric vehicle blended cathodes via selective leaching and direct recycling,’ published in ChemRxiV, showed that ascorbic acid selectively leaches low-value electrode material.

This leaves the higher value nickel and cobalt-based material in a solid state – from which it can be directly recycled.

The work has been patented by the University of Birmingham Enterprise.

The new method has potential for simplifying battery recycling

Current battery recycling methods concentrate on recycling elements by dissolving battery cathodes using strong acids. This poses an additional problem of disposing potentially hazardous waste from the recycling process.

It also relies on the initial shedding of the batteries, which mixes components and creates a jumble of chemistries that can only be separated through chemical processes.

Professor Peter Slater, co-inventor of the new battery recycling method, commented: “Battery chemistry, and cathode chemistry in particular, is constantly evolving to meet the demand for greater energy density.

“However, battery recycling has remained relatively static, and has focused on breaking down the cathodes into their individual element components particularly when recycling mixed chemistries, which loses a lot on the internal value of the cathode material.

“The challenge with recycling mixed chemistries is to separate out the low and high-value materials. Our method removes the low-value material, while leaving the high-value material in a solid state, so it can be directly recycled, maintaining its high value.”

Research from a real-world perspective

The research team started by looking at what is actually going into recycling chains.

They chose a battery from a Nissan Leaf because this was the first mass-market electric vehicle. Because of this, both the car and its batteries will be among the first to enter recycling chains and the recycling industry.

Professor Slater concluded: “Our battery recycling method will reduce the cost and number of steps to recover cathode materials, so they can be remanufactured and put back into new batteries, with minimal environmental footprint.”

Scaling up the new approach

The team is now working on scaling up the new battery recycling approach. They are looking for long-term partners for pilot studies, to deliver this technology to existing infrastructure, or to collaborate on further research to develop the system.

The research is part of the ReLiB project, a multi-institution consortium of researchers funded by the Faraday Institution and led by the University of Birmingham. The project aims to improve the speed, economics, and the environmental footprint of the recycling process.