The Federal Ministry of Research in Germany has invested €3m into the EPIC project, which aims to improve the electrode drying process for lithium-ion batteries.

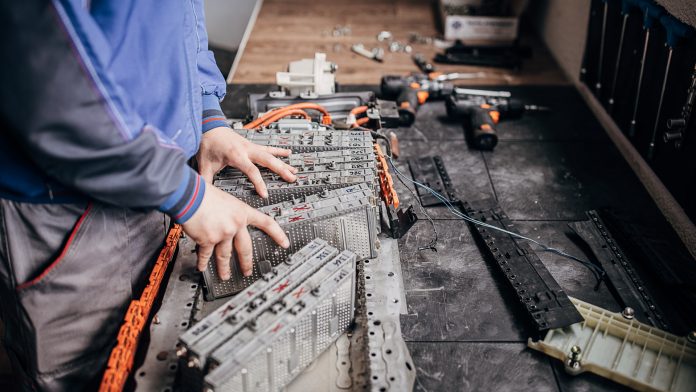

The new EPIC project, co-ordinated by Karlsruhe Institute of Technology (KIT), is aimed at accelerating the electrode drying process for lithium-ion batteries, reducing the cost of battery production. The quality of lithium-based battery cells depends on the electrode layers which are used for energy storage.

The creation of electrodes uses a lot of energy and can be time-consuming for producers, resulting in high production costs. Researchers from the Thin Film Technology (TFT) group at KIT have now developed an innovative coating process, by which electrodes for lithium-ion batteries can be quickly produced. “It is important to analyse the individual process steps together and to consider interactions,” says Professor Wilhelm Schabel, head of TFT.

The project aims to reduce overall battery production costs for electrode drying by at least 20%. Scientists from the EPIC project plan to increase the drying speed by at least 50%, while maintaining the quality and long-term stability of the electrodes. “Higher coating speeds are particularly attractive when drying time can be reduced and the expensive drying line does not have to be extended,” says TFT researcher Dr Philip Scharfer.

KIT will study drying directly in the cell stack prior to electrolyte filling, as well as the adjustment of the required cell moisture. A collaborative study between researchers from KIT and the Technical University of Braunschweig will evaluate how the drying intensity and duration influence cell properties. Once the different approaches to production have been evaluated by the project partners using suitable process-cost models, recommendations will be made for transferring the process to the industrial scale. Latest findings in production technology will be incorporated directly in the Post Lithium Storage (POLiS) cluster of excellence, in which KIT will develop future batteries together with Ulm University and ZSW.