Researchers in Sweden have produced a green alternative to reduce reliance on mining graphite, the raw source behind the next wonder material, graphene oxide.

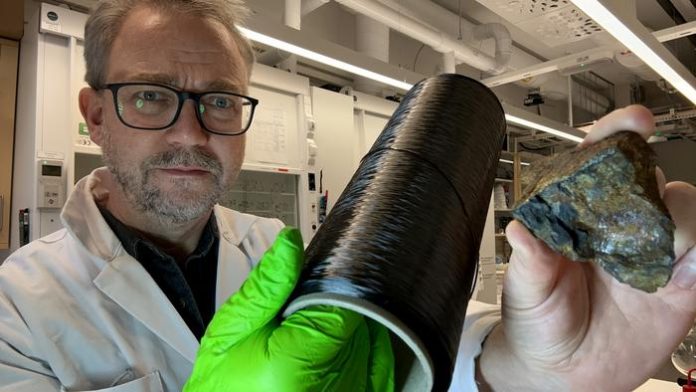

The team from KTH Royal Institute of Technology have developed a reproducible and scalable method for producing graphene oxide (GO) nanosheets from commercial carbon fibres, marking a breakthrough in sustainable nanomaterial synthesis.

The process involves exfoliating carbon fibres with nitric acid, which provides high yields of one-atom-thick sheets of graphene oxide with characteristics comparable to commercial GO sourced from mined graphite.

Issues with current graphene production

Graphene oxide is a widely studied nanomaterial that can be used in car batteries when its thin sheets stack together, forming layers similar to graphite.

It is also useful in high-performance composites, water purification and electronic devices. However, synthesis from mined graphite requires harsh chemicals and often results in material inconsistencies due to variations in graphite purity.

Richard Olsson, professor in polymeric materials at KTH, says the proof of concept was carried out with carbon fibres derived from polyacrylonitrile (PAN), a widely available polymer that undergoes high-temperature oxidation and graphitisation.

He said the method could be duplicated with other raw sources, such as raw sources such as biomass or forest industry side streams.

Uses in EV batteries

Olsson points to the electric vehicle battery market as one that can benefit from the new technology.

“The core of graphite battery functionality can be found in the layered graphene inside, which can be harvested from commercial carbon fibres using this method,” he explained.

“The future of auto manufacturing will build on battery-based power, and the question is where the graphite will be sourced. They are going to need alternatives.”

Transforming carbon fibres for green production

The method consists of transforming the carbon fibres using the process of electrochemical oxidation in a bath of water and nitric acid.

The bath acts as a conductor, and when an electric current is sent through carbon fibre, the material begins to lose electrons, which transforms the surface much the same way that oxidisation appears as rust on a car.

In this case, the transformation causes layers of nanoscale graphene oxide to peel off from the carbon fibre’s surface.

The study discovered a window in which just 5% nitric acid was perfect for creating these tiny nanosheets, ranging from 0.1 to 1 micrometre in size, with a uniform thickness of about 0.9 nanometres.

Notably, the GO nanosheets synthesised this way emerged in circular and elliptical shapes, in contrast to the polygonal shapes typical of GO synthesised from natural, mined graphite.

Compared to existing synthetic methods, the new approach delivers a high yield of 200 milligrams of GO per gram of carbon fibre. This efficient conversion rate makes it viable for large-scale production, addressing a key challenge in nanomaterial synthesis.

Ensuring quality standards of the new graphene nanosheets

To ensure the graphene oxide nanosheets met quality standards, the researchers examined and measured the properties and structure of the material with a number of advanced techniques.

The study also explored methods to remove protective polymer coatings from commercial carbon fibres before oxidation, heating at 580°C for two hours and shock-heating to 1200°C for three seconds—both proving effective.

The research demonstrated that the nature of electrical conduction within the graphene fibres plays a crucial role in the electrochemical exfoliation process.

Olsson concluded that the next step for the research includes investigating biobased sources for carbon fibres to delve deeper into how the process works.