Drexel University researchers have created an optimisation system for electric vehicle batteries to manage durability, weight, and thermal activity.

With car manufacturers increasingly investigating carbon fibre-based structural batteries as lithium-ion alternatives, researchers at Drexel University in Pennsylvania have developed a design optimisation system for electric vehicle (EV) batteries to maximise their range and reliability.

Packing enough energy into a battery to power a car is putting a lot of pressure on the storage devices that, for the last century or so, have mainly been tasked with running small appliances and electronics. The stress can result in malfunctions and diminished performance.

In a paper recently published in the journal Composites Part B: Engineering, a research team led by Drexel’s Ahmad Najafi, PhD, an Assistant Professor in the College of Engineering, developed a design optimisation system for incorporating a blood vessel-like cooling network into the packaging of a new generation of carbon-fibre based batteries utilised in EVs.

Their method balances performance-enhancing factors – such as battery capacity and conductivity – against problematic variables, including weight and thermal activity, to provide optimal EV battery package specifications.

A new generation of electric vehicle batteries

As the demand for EVs has been impacted by rising climate change concerns and increasing gas prices, the market has been tempered by growing concerns of the safety and the durability of EV batteries.

As a result, more companies are considering the use of solid batteries – a thin, carbon fibre-based version of the larger lithium-ion batteries widely utilised in EVs — because they can be cleverly incorporated into the physical structure of the vehicle chassis to reduce the weight.

Additionally, trimming the weight of a car by just 10% can boost its mileage efficiency between charges by as much as 6-8% according to some estimates. Thus, replacing portions of the car frame with a carbon-fibre composite that functions both as a structural component and as a battery, could reduce the overall weight of the vehicle as well as improve its energy storage capacity.

Managing EV battery thermal activity

In order for these structural, or ‘massless’, batteries to succeed, designers must confront a challenge that arises from their use of a solid polymer — rather than a liquid electrolyte solution — as its medium for electron transit.

“Heat generation will be substantially higher in structural batteries in comparison with standard lithium-ion batteries,” Najafi explained.

This is because the conductivity of the polymer electrolyte is much smaller than that of the liquid electrolytes utilised in lithium-ion batteries. This means that electrons face more of a bottleneck as they move through the polymer, resulting in them moving slower and generating more heat as the battery discharges its energy.

“While structural battery composites are a promising technology for reducing weight in EVs, their design could certainly benefit from the addition of a thermal-management system,” added Najafi. “Not only could this improve the range of the EV, but it would also greatly reduce the chances of a thermal runaway reaction.”

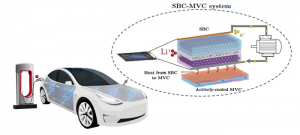

To remedy this issue, Najafi’s research group utilised nature’s cooling method of the vascular system to dissipate heat. Thus, by modifying a design tool they invented to plot the optimal ‘microvascular’ network, the researchers were able to design cooling composites that would work as part of the structural battery packaging currently being tested by companies like Tesla, Volvo, and Volkswagen.

The design system, presented by Najafi’s team in their latest research, can calculate the best pattern, size, and number of microvascular channels to quickly dissipate heat from the batteries. This also means that the design flow is optimised for flow efficiency of the coolant moving through the channels.

“The coolant draws in the heat and pulls it away from the battery composite as it moves through the network of microchannels,” explained Najafi. Sandwiching the structural batteries between layers of cooling microvascular composites can stabilise their temperature during use and extend the time and power range in which they can function.

Optimisation system for EV batteries

The research team’s structural battery optimisation process considers several design parameters, such as thickness and fibre directions in each layer of carbon fibre, the volume fraction of fibres in the active materials, and the number of microvascular composite panels required for thermal regulation.

According to the research, computer models of one optimised system revealed that it could improve the driving range of a Tesla Model S by as much as 23%. However, the team noted that the real value of their work is its ability to glean the best combination of battery size and weight —including enough cooling capacity to keep it functioning — for any EV currently in production and any future designs.

“While we know that every bit of weight saving can help improve the performance of an EV, thermal management can be just as important – perhaps more, when it comes to making people feel comfortable driving them,” Najafi said. “Our system strives to integrate improvements in both of these areas, which could play an important role in the progress of EVs.”