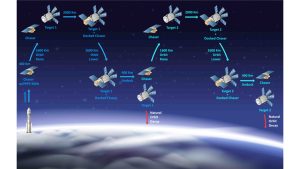

To provide a “responsible space” option to existing and future satellite manufacturers, Champaign-Urbana Aerospace (CUA) has developed multiple innovative micropropulsion systems that represent tipping point technologies for future integration and flight on micro/nanosatellites.

The CUA family of micropropulsion systems provide a broad range of capabilities from high thrust to high specific impulse to best suit the needs of the customer. Advantages of CUA’s life-cycle propulsion solutions include:

- Collision avoidance

- Orbit raising and lowering

- Inclination change

- Rendezvous

- Drag makeup and orbit maintenance

- Deorbiting at end of satellite useful life

Collision avoidance and deorbiting satellites dramatically help to avoid the escalation of the growing orbital debris problem, which ultimately could lead to what is known as the “Kessler syndrome,” a catastrophic space scenario where there is so much debris in low Earth orbit (LEO) that the probability of collision is high enough that it is no longer safe to launch spacecraft into or through the debris field.

The deorbiting capability of CUA’s different technologies enables satellites to meet the U.S. Federal Communications Commission (FCC) relatively new 5-year deorbit rule. This is especially important for satellites having altitudes higher than atmospheric drag alone or passive deorbit deployment options can handle.

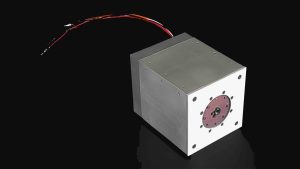

Fibre-fed Pulsed Plasma Thruster (FPPT)

CUA’s fibre-fed pulsed plasma thruster (FPPT) vaporizes Teflon and accelerates the resulting ions using a high-energy 10-microsecond pulse providing a very high specific impulse of >3500 s. The Teflon fibre is spooled in the back of the package and fed into the centre of system (Fig. 1). The high specific impulse and total impulse are competitive with Hall and ion-thruster technologies at much lower cost and without the need for a pressurized propellant tank or valving that can leak propellant. The system also includes electromagnetic thrust vectoring (steering) of approximately ±5 degrees in the pitch and yaw axes. The FPPT, through its electromagnetic short-pulse discharge, provides a dramatic increase in total impulse to > 25,000 N-s in a 1.7-liter sized package. FPPT has now evolved into various form factors ranging from 0.7-liter to 53-liter sizes to provide a broad range of total impulses from 1,000 – 600,000 N-s, respectively. FPPT technology is a compelling option to meet many micropropulsion needs, including extended orbital manoeuvres (orbit raising and lowering), inclination change, collision avoidance manoeuvres, drag makeup, deorbiting, and even deep space capability. The newest ESPA-class FPPT can also serve as the propulsion system for active debris removal (ADR) satellites (Fig. 2).

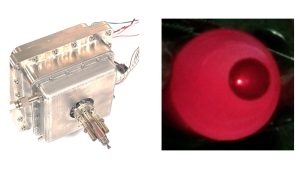

Monofilament Vaporisation Propulsion (MVP)

The Monofilament Vaporization Propulsion (MVP) system draws from extrusion 3D printer technology to feed and melt Delrin fibre propellant (a common polymer). MVP then uses a low power resistojet to vaporize the Delrin propellant and provide continuous electrothermal thrust with a specific impulse of 66 s. The Delrin fibre is spooled in a cylindrical configuration surrounding a core containing all the electronics inside the package. This technology retains performance characteristics competitive with other warm gas systems, but enables more accessibility to micropropulsion via dramatically reduced cost and the elimination of range safety concerns. A 0.93-liter sized MVP (see Fig. 3) has a total impulse of 265 N-s and is a compelling option to meet many micropropulsion needs, including collision avoidance manoeuvres, limited orbit raising/ lowering, drag makeup, and deorbiting.

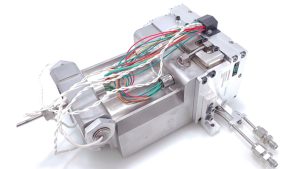

Cubesat High Impulse Propulsion System (CHIPS): Robust multi-purpose option

CUA’s Cubesat High Impulse Propulsion System (CHIPS) is a miniaturized, well-integrated propulsion solution tailored for small satellites, combining both a main thruster and a three-axis attitude control system (ACS). Utilizing CUA’s high efficiency resistojet (superheater) technology and non-toxic, inert propellants, CHIPS offers impressive performance in a compact package. Proven valving has been cycled to >120 million actuations and can be used with self-pressurizing, non-toxic, and inert propellants. Waste heat from the electronics and resistojet is efficiently and regeneratively recovered to evaporate propellant, resulting in low system temperature rise (~1°C) over 10-minute operating cycles.

CHIPS technology provides a great deal of mission flexibility with minimum risk providing a powerful, customizable propulsion system with minimal size requirement. The all-welded CHIPS-180 (see Fig. 4) is an ultra compact 0.54U fully throttleable system having 180 N-s of total impulse with refrigerant R134a as its propellant. CHIPS technology can be customized in size to meet customer-specific mission requirements. While CHIPS’ warm-gas resistojet specific impulse is 40-50% higher than cold-gas Isp, CHIPS can also be packaged as a cold-gas-only system requiring reduced power. The CHIPS package can incorporate up to 8 ACS thrusters for 6 degree-of-freedom (6DOF) operation.

Monopropellant Propulsion Unit for Cubesats (MPUC): Safe high thrust option

CUA has developed a high thrust option using an ethanol and hydrogen peroxide monopropellant mixture. This monopropellant, designated CMP-X, is a non-detonable yet energetic COTS formulation (see Fig. 5) that possesses many system-level advantages over legacy monopropellants (such as hydrazine), including lower cost, lower thermal load (approximately 950°C flame temperature, see Fig. 5), water-like viscosity, common materials compatibility, and an additively-manufactured thruster head. CMP-X is designed as a monopropellant option for customers who can accept a modest performance trade-off for the advantages of lower cost, easy transportability, considerably fewer range safety concerns, longer continuous thrust burns, and lower flame temperature resulting in considerably less thermal soakback into the spacecraft. CMP-X retains the ability to scale in thrust magnitude and requires minimal catalyst bed warmup time. CUA’s CMP-X thrusters have demonstrated a steady 178 s specific impulse at 230 mN thrust during thrust stand testing with continuous firing times > 50 min. A 2-liter sized MPUC would have a total impulse >2,000 N-s. Other advantages include: (i) thrust can be throttled, (ii) the thruster and system are scalable for high thrust greater than 10s of Newtons, (iii) the monopropellant is non-detonable, non-explosive, and has received UN 1.4S transportation classification, (iv) attitude control thrusters can be readily added, and (v) CMP-X is well-suited for larger CubeSats and small satellites.

Cycle Automated Mass Flow (CAMFlow) technology: Low-cost precision flow control

The Cycle Automated Mass Flow (CAMFlow) system (Fig. 6) provides reliable and well-regulated flow control for electric propulsion systems. CAMFlow uses an innovative control scheme that enables stable operation using fixed frequency Boolean valve states, even for the low flow rates necessary for sub-kiloWatt Hall effect thrusters. This methodology removes system complexity, places the onus of reliability on valve cycle life, and, combined with the fixed operational frequency, allows for a direct correlation between system life and valve cycle life. The CAMFlow control scheme was successfully tested and validated on a 600-Watt Hall thruster. This included open loop, closed loop, and cold “hard” start operations. The control valves were cycled > 120 million pulses while maintaining a very low leak rate, thereby demonstrating long-life potential. CAMFlow units are presently focused on smaller Hall-effect or gridded-ion electric propulsion systems, however, the technology is widely applicable over a larger range of flow rates for a broader commercial market. The CAMFlow system controls the output flow rate to < ±3%. Through the use of less expensive space-rated components, CAMFlow technology provides a reliable, low-cost flow controller that is well-suited for sub-kiloWatt Hall/ion thrusters.

Dual Propulsion Experiment (DUPLEX) CubeSat: 2-for-1 flight demonstrator

NASA’s Space Technology Mission Directorate (STMD) funded CUA for the design, fabrication, launch and in-space demonstration of the Dual Propulsion Experiment (DUPLEX) CubeSat (see Fig. 7). DUPLEX is a 6-liter-sized satellite that will perform an in-space demonstration of CUA’s innovative FPPT and MVP micropropulsion technologies to provide flight heritage for these systems. The launch of the DUPLEX spacecraft will be manifested in the first half of 2025. The DUPLEX flight demonstration will significantly lower the risk for future customers of the MVP and FPPT systems and raise the Technology Readiness Level (TRL) of these innovative thruster technologies.

Future vision

CUA’s family of micropropulsion systems are now developed for flight and will help the industry to provide a responsible and sustainable space environment in which the growing number of satellites can safely coexist. The CUA family of high-value (quality performance at reduced cost) system options provides a broad range of capabilities to best suit differing customer mission needs. Further, affordable propulsion options will enable future satellites life-cycle propulsion solutions to perform collision avoidance, orbital trajectory change, and deorbiting manoeuvres to impede the escalation of the growing orbital debris problem.