Toyota electric car batteries are set to have more than 1000km driving range, the company has announced in a new battery strategy.

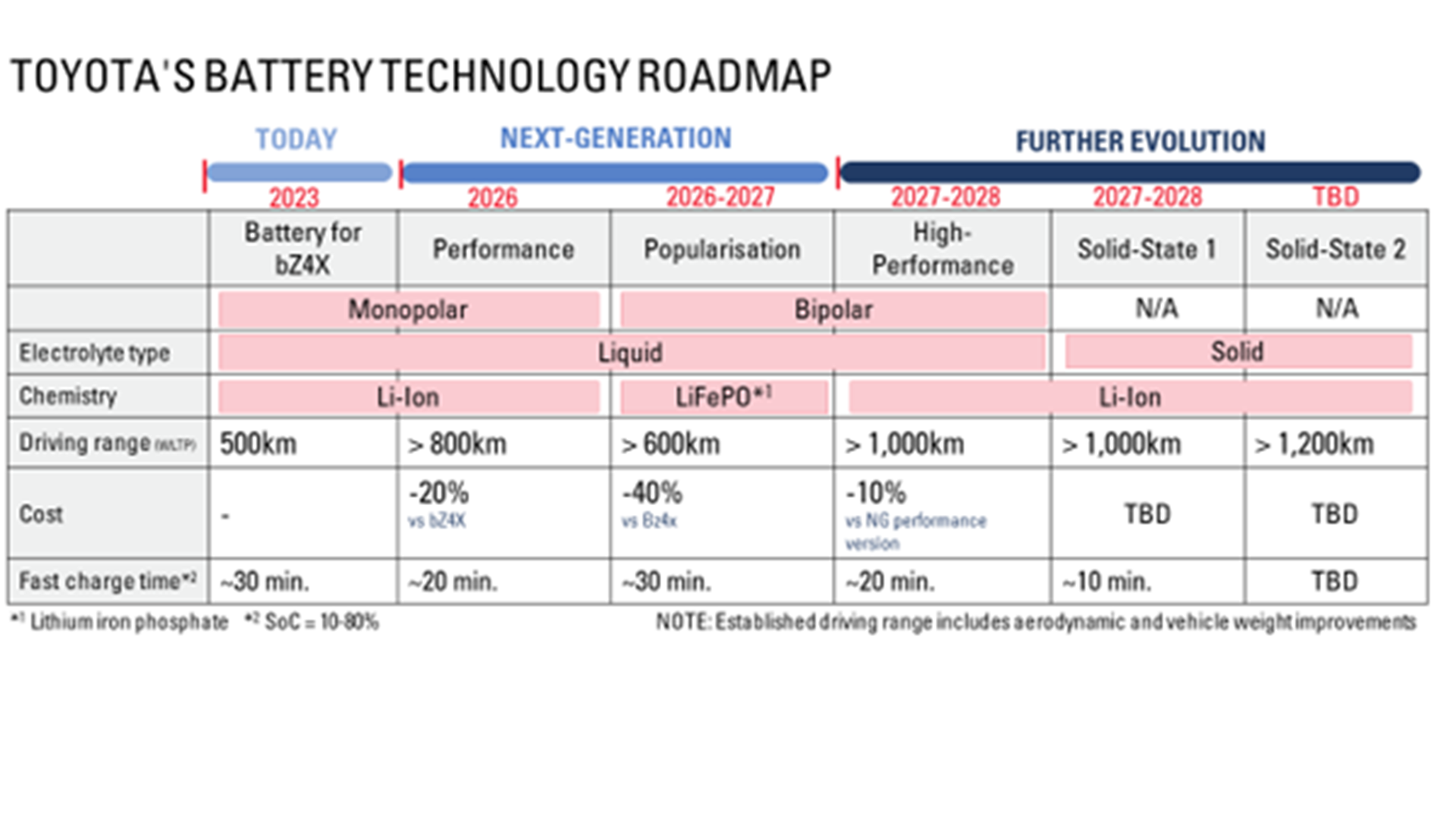

The company’s battery technology roadmap has revealed plans for four next-generation Toyota electric car batteries, which include innovations in liquid and solid electrolytes.

Toyota is currently developing a new battery electric vehicle factory that will begin producing new models in 2026.

These models will be powered by the new cutting-edge Toyota electric car batteries that make the Japanese car manufacturer an industry leader in driving range capabilities.

Takero Kato, president of the new production facility, explained that these models will account for 1.7 million of the 3.5 million battery electric vehicles Toyota expects to sell worldwide by 2030.

He said: “We will need various options for batteries, just as we have different types of engines. It is important to offer battery solutions compatible with a variety of models and customer needs.”

Advancing liquid electrolyte batteries

Liquid electrolytes are the primary battery technology used to power battery electric vehicles.

In the company’s new roadmap, Toyota outlines plans to increase energy density, cost competitiveness, and charging speeds.

The main types of Toyota electric car batteries under development are: Performance, Popularised, and High Performance.

Performance

Toyota’s ‘Performance’ lithium-ion batteries will be rolled out in new models from 2026, increasing driving range to over 800km.

They will also reduce costs by 20% compared to the current Toyota bZ4X and provide rapid charging times of 20 minutes or less for a state-of-charge (SOC) between 10-80%).

Popularisation battery will increase range by 20%

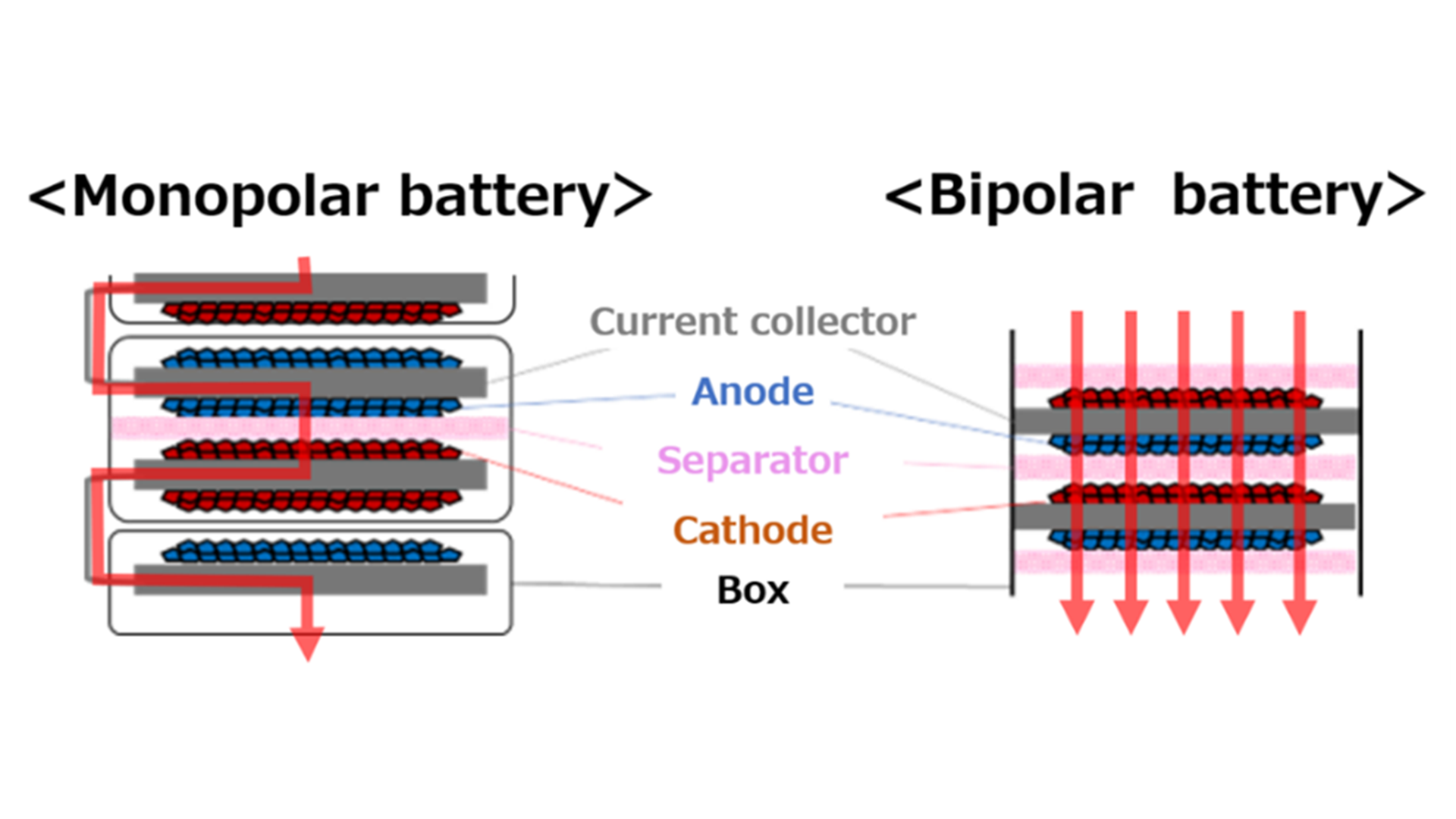

The ‘Popularisation’ battery will be manufactured using Toyota’s bipolar technology used for its nickel-metal-hydride (NiMH) batteries but will be combined with inexpensive lithium iron phosphate (LiFePo) as the core material.

This will increase the driving range by 20% compared to the Toyota bZ4X and cost reduction by 40%, with a fast recharging time of 30 minutes or less for SOC of 10-80%. This battery is expected to reach the market in 2026-2027.

1000km high-performance range

Toyota’s High-performance lithium-ion battery will amalgamate the bipolar structure with lithium-ion chemistry and a high nickel cathode.

This will yield a driving range of more than 1000km and a further 10% cost reduction compared to the Performance battery.

This battery is expected to be developed by 2027-2028 and will have a rapid charging time of 20 minutes or less for SOC 10-80%.

Advancing solid-state batteries

Solid-state Toyota electric car batteries are set to improve significantly, boasting faster movement of ions and greater tolerance to high voltages and temperatures.

This will allow for rapid charging and discharging, with a charging time of ten minutes or less for SOC 10-80% and a 20% driving range increase compared to the Performance battery.

The company is also developing a higher-specification lithium-ion solid-state battery with a 50% improvement in cruising range compared to the Performance model.

Aerodynamic improvements will increase driving range

Toyota aims to improve the drag coefficient (Cd) rating of its vehicles to boost range capacity further. The company is focussing on CdA – the drag coefficient multiplied by A (the front area of the vehicle).

To improve this, Toyota is optimising the height of the battery. This is because the battery is usually located beneath the vehicle floor, which can increase the vehicle’s overall height.

The height of the vehicle has a disproportionate, multiplied effect on the CdA, which can decrease the vehicle’s range. By reducing the battery height, Toyota expects huge range increases.

For example, the Toyota bZ4X is around 150mm high. The company plans to reduce battery height to 120mm and 100mm in sports models to improve range considerably.