Water scarcity is pushing new treatment technology adoption, but the emerging lithium market is accelerating implementation.

The case for water conservation and preservation is becoming increasingly severe. Shortages in water supply, decline in water quality, and, in some instances, complete loss of access to water has become increasingly common across the globe. Unfortunately, these water issues are no longer attributed to just developing nations or arid regions but can now be seen and felt by all in the form of dried-up lake beds, collapsed and depleted aquifers, and rivers that no longer flow to their once destination. According to UN-Water, 1.8 billion people will be living with absolute water scarcity by 2025.1 In California, water supply for farmlands increased in cost by as much as ten times in 2022;2 in British Columbia, Canada, an area designated as rain forest was under severe drought restrictions in the fall of 2022;3 and in 2017 Cape Town in South Africa hit ‘day zero’ – the day water reservoirs were essentially dry and government was forced to turn off the water supply.4

Even Europe is seeing barriers to manufacturing, when in 2022 Tesla stalled on its electric vehicle (EV) plans due to water restrictions.5 The lack of water poses a major threat to several sectors, including industrial manufacturing, transportation, and even food security. If water scarcity continues to escalate, will people and industry begin to compete for it or, worse, fight for it? If we are to turn this corner, we need to begin managing our water better but, more importantly, we need to begin valuing water as a resource. For industrial processes, the ability to reuse water could be the difference between having an economic and sustainable operation versus going out of business because of no water. Enhanced water conservation has highlighted the mandate for the adoption of new methods in wastewater treatment, such that the valuable water contained within them can be extracted, purified, and reused back in the industrial processes or returned to the environment for the recharging of aquifers or refilling of water supplies.

There are solutions to the water scarcity issue. While relief of water stress will take efforts on multiple fronts, one of those battle grounds will be focused on the industrial use and reuse of water. Globally, 359 billion cubic metres of industrial wastewater is produced each year and only about 50% is treated.6 Recovering water cost-effectively, with minimal energy requirements, is achievable today using more advanced and currently available technologies. For existing plants, upgrading or modifying existing wastewater treatment processes could essentially mean that water entering a plant could be reused indefinitely, making it a one-time purchase and a resource of the plant. As an example of this, the L’Oréal Groupe has committed that, by 2030, 100% of the water used in its industrial processes will be recycled and reused in a continuous water loop.7

Advancing conventional wastewater treatment plants with membrane solution pathways

Over the last few decades, advancements in technologies and methods for the treatment of industrially contaminated waste streams have appeared more frequently. The most prominent of these advancements has been the emergence of new membrane-based technologies capable of transitioning conventional wastewater treatment plants into advanced sustainable reuse facilities. The most mature of the membrane technologies is reverse osmosis (RO), having a projected market size of $13.5bn by 2025 with a compound annual growth rate (CAGR) of 8.7%.8 This market growth is being partly driven by water scarcity, new treatment mandates for industrial and municipal wastewater applications and, more recently, brine management as a result of more desalination plants being built to meet drinking water demands.9

The need and demand for more water has led to the development of new membrane technologies and the evolution of others. Recent membrane technology developments include osmotically assisted reverse osmosis (OARO), closed-circuit reverse osmosis (CCRO), membrane distillation (MD), and forward osmosis (FO). FO is a good example of technology evolution, realised only by the advancements in chemistries and material sciences over the past 15 years. FO has leveraged these advancements through the use of newly commercialised water selective membranes, and use of a new thermolytic draw solution (TDS), delivering higher water recovery rates at lower energies. The net result of these advancements is that large amounts of clean water can be extracted and recovered from wastewater using the free osmotic energy contained in the ‘draw’ solution. Historically, the challenge with commercialising FO technologies has been in identification of economically viable draw solutions which are easy to regenerate with minimum energy demands. The selection and use of a thermolytic draw solution meets this challenge. FO thermolytic draw solutions are capable of delivering a 40-50% energy reduction to that of conventional thermal evaporation (TE) regarding extraction and production of clean water.10 Since FO uses less energy than TE, FO has a much smaller carbon footprint, proving to be beneficial for companies looking to improve their environmental, social, and governance (ESG) rating. Additionally, since FO uses osmotic energy to draw water across a semi-permeable membrane and not pressure, common challenges/problems associated with RO operations, such as solids compaction/compression, pore blockage and irreversible flux loss, have been eliminated or minimised due to FO’s robust operating nature.

Forward Water Technologies

Forward Water Technologies Corporation has commercialised its industrial MAX-FOTM process for difficult-to-treat waste and process waters that have few wastewater treatment alternatives other than deep well disposal or high-energy bulk boiling evaporation.

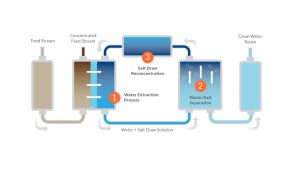

An industrial FO process typically uses a three-step approach. The first step is where a membrane is used to extract water from a waste or process stream. Water extraction is a function of membrane permeability and osmotic potential of the draw solution. Osmotic potential is related to the type of draw solution used and should develop a very high osmotic potential difference between the feed and draw solution. As the osmotic potential is the force causing water to transport across the membrane, the higher the osmotic potential, the greater the water transport. To maximise osmotic potential, the FO process must be designed such that the draw solution is kept at the highest possible concentration while water is being transported into it. The net result of the water transfer leads to a concentration of the feed solution and dilution of the ‘draw’ solution referred to as a dilute draw solution (DDS). To maintain a high concentration of draw solution during operations, the DDS needs to be reconcentrated or regenerated continuously within a closed loop process. Forward Water Technologies accomplishes this by use of a thermolytic draw solution.

A thermolytic draw solution is preferential as it allows FO systems to operate at significantly higher TDS levels, well beyond the limits of RO. The uniqueness of a thermolytic draw solution is in its ability to convert from a dissolved salt to a gas and leave solution when low-grade heat is applied to it, resulting in clean water being left behind. In contrast, a thermal evaporator is a bulk boiler, using pressure and high temperature in the production of distilled water. As described, the operational difference between FO and TE is significant with FO energy usage being 40-50% less. To regenerate the CDS, the evolved gases are captured and recycled back into CDS in an adsorption process, which is step three of the FO cycle. This three-step FO process results in higher water recovery, lower energy requirements, and a continuous loop regeneration process.

As early as 2019, Forward Water scaled the process for refinery wastewater treatment and treatment of produced water from the oil and gas industry in Alberta. Thus, it was shown that the MAX-FOTM technology was scalable, capable of dealing with challenging waste streams, and achieved the operational goals of clean water recovery at a relatively lower energy input compared to transportation and disposal or forced evaporation.

Key to advancing the commercialisation of Forward Water’s MAX-FOTM process is focusing on sectors where rapid adoption will take place. In broad terms, that is industrial manufacturing, mining or mineral extraction, and food and beverage processing waste. When combined, these sectors represent a $67bn opportunity.11a,b,c While each of these industries have differing commercial outputs, they all result in compromised wastewater suited for treatment by an FO process.

Brine management and lithium capture

In the development of FO designs in association with various markets and applications, it became apparent that test data derived from FO benchtop testing and FO piloting of client process and wastewater streams were delivering better performance than predicted. Increases in FO performance meant higher water recovery rates and lower operating costs, allowing us to engage new applications such as brine management. Brines can be defined as high salinity, high mineral content or both; can be found as manmade or in nature; and can have value by the purpose they serve (pickling brine) or by the minerals/metals they contain. In either case (manmade or naturally occurring brines), the ability to extract water and concentrate these to the highest possible level provides benefits to their handling, management, and processing. Recognising Forward Water’s MAX-FOTM ability to concentrate these brines, several new markets have emerged to meet client needs.

One such market where FO is delivering new and added value to that of conventional TE is in the recovery of lithium from unconventional lithium brine sources, used in conjunction with direct lithium extraction (DLE). A DLE process ‘directly’ extracts and loads lithium onto either an ion exchange or absorption material as lithium brine is passed over and through it. The higher the lithium content in the brine, the faster and easier it is to load lithium onto the DLE material. Unconventional lithium sources, such as geothermal and oilfield brines, commonly contain lithium concentrations between 75-200 ppm. This low lithium content means that bigger pumps, greater brine volumes, and higher capital costs are needed to load lithium onto the DLE material. The MAX-FOTM process, in many cases, can concentrate unconventional lithium brine sources by as much as ten times, resulting in increased lithium concentration and the transformation of unconventional sources into economically viable production sites. It is estimated that the unlocking of unconventional lithium brine sources could allow 25 million tonnes of LCE production to be realised.12

Lithium supply and demand challenges

In 2022, the demand for lithium has grown rapidly and the supply side has been unable to keep pace with an intensifying demand. This gap in the supply chain is expected to continue to at least 2040.13

Moreover, supply of battery-grade lithium is projected to be largely sourced from underground brines contained versus hard rock mining. The multi-step collection of lithium from these brines has some significant constraints. Many of the DLE procedures accompanied by the upstream and downstream treatment needs are all aqueous brine processing in nature. Process costs are a significant consideration and in many, if not all cases, a concentrated process stream provides the best benefits in DLE extraction kinetics and in post DLE processes, and contaminant removal. These concentrated brine and lithium streams lead to lower capital footprint, better yields, lower costs, and higher purities than might be otherwise expected. Furthermore, the reclamation of the water from lithium operations can also be a critical consideration as many of these lithium sources are in water-stressed or arid regions and withdrawing water without replacing it creates large barriers for the operators as local communities resist industries that do not address water conservation directly. Lastly, in running DLE operations and lithium purity refinement, a critical consideration is the power demand requirement in these processes. The renewable materials industry cannot be a large energy consumer, especially if that power is generated using traditional hydrocarbon-based or coal-based energy generation. Thus, the desired brine concentration cannot rely on traditional methods of forced evaporation using, for example, multi-effect thermal evaporation.

Forward Water’s Li-FOTM treatment process, developed specifically for aiding lithium capture, enables the concentration of water-based process brine streams, leading to lower operational and reduced capital costs as a result of its substantially lower power requirements which have been shown to be far less than that of evaporation to the point where the CO2 footprint is only 50% of the equivalent multi-effect evaporator.10 Additionally, the Li-FOTM process also returns clean water back to the original source or makes it available for other industrial uses. Further studies have also revealed that the thermal demand can be provided by solar-thermal facilities, making the water recovery and reuse even more effective in terms of cost and reduced CO2 emissions. Currently, Forward Water is working with several global mining companies in the development and support of their lithium DLE processes and in ensuring no or minimal environmental impact by maximising water recovery for reuse and minimising CO2 emissions.

Summary and future outlook

The combination of more stringent water regulations, higher increasing costs of operations, and the drive towards net zero emissions has positioned MAX-FOTM and Li-FOTM processes as an innovative solution in meeting the needs of today’s clients. Thermolytic draw recycling, in combination with advanced membrane materials, is setting new and lower energy benchmarks in water recovery and CO2 emissions. With each success, Forward Water helps in the global transition towards water sustainability by replacing conventional technologies with cleaner, more efficient ones. FO is continuing to find new markets and new applications as clients realise the inherent opportunities now afforded to them by FO operations – higher water recovery, higher concentration factors, greater volume reduction, and lower energy requirement. Can your process or wastewater treatment system be improved by one of these FO benefits?

References

2. https://www.cnn.com/2022/11/01/us/california-water-cost-profiteering-climate

3. https://globalnews.ca/news/9205042/sunshine-coast-drought-emergency/

4. https://time.com/cape-town-south-africa-water-crisis/

6. https://www.aquatechtrade.com/news/wastewater/50-per-cent-of-wastewater-now-treated-worldwide/

8. https://www.alliedmarketresearch.com/reverse-osmosis-membrane-market

10. Third-party studies have projected that MEE would require energy resulting in 197.4 kg CO2 released, compared to 98.6 kg for the same treatment needs using FWTC’s FO process

11b. Flavoring Syrup and Concentrate Manufacturing Market Global Briefing 2019, The Business Research Company, June 2019

12. https://www.fastmarkets.com/insights/unconventional-lithium-sources-can-it-fill-the-supply-gap

13. Benchmark Minerals 2022

Please note, this article will also appear in the thirteenth edition of our quarterly publication.