An international research team has discovered an enzyme system for the hydrogen industry that can produce hydrogen using electricity and vice versa.

The research team includes participation from researchers at the Technical University of Munich (TUM), Ruhr-Universität Bochum (RUB), the French National Centre for Scientific Research (CNRS), and the Max-Planck Institute for Chemical Energy Conversion and has been published in the journal Nature Catalysis.

Fuel cells convert hydrogen into electricity, while electrolysers use electricity to divide water to generate hydrogen. Both processes require platinum – a rare and expensive metal – as a catalyst.

However, now, another solution has been discovered: enzymes, known as hydrogenases, that quickly catalyse the conversion of hydrogen and with almost zero energy loss.

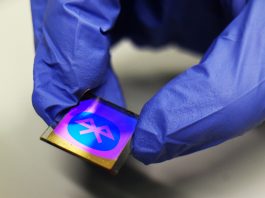

Previously, these biocatalysts have not been deemed appropriate for industrial use as they are highly sensitive to oxygen. Now, the researchers have been able to insert the sensitive enzymes in a protective polymer in a manner that makes them feasible for use in technical hydrogen conversion.

“When the sensitive hydrogenases are embedded in suitable polymers they continue to work for several weeks, even in the presence of oxygen,” commented Nicolas Plumeré, Professor for Electrobiotechnology at the TUM Campus Straubing for Biotechnology and Sustainability. “Without this protection they lose their activity within a matter of minutes.”

Inserting the hydrogenases in polymers whose side chains can transfer electrons – redox polymer – does have drawbacks: a high level of resistance offsets the flow of electrons through the redox polymer. This necessitates the investment of energy which is then lost as heat, and the embedded hydrogenases lose their capacity to generate hydrogen.

The group has now succeeded in setting the redox potential of the polymer in such a way that only a small overvoltage is necessary to overcome the resistance.

With further analysis, the team discovered that the potential of the side chains marginally shifted to more positive values as a result of the embedding in the polymer matrix. In additional studies, the group used a side chain with a corresponding negative potential, which led to a breakthrough: the hydrogenase could catalyse the reaction in both directions without energy loss.

The team then developed a fuel cell whereby oxygen is decreased by the enzyme bilirubin oxidase from the bacterium Myrothecium verrucaria, while the hydrogenase implanted in the polymer film oxidises the hydrogen from the bacterium desulfovibrio desulfuricans, producing electricity in the process. This method can also be utilised for the reverse reaction, generating hydrogen by consuming electrons, with the effectiveness of energy conversion close to 100%.

“The reduction in energy loss has two decisive advantages,” explained Nicolas Plumeré. “First, it makes the system significantly more efficient; second, the heat generated in a fuel cell stack at high performance levels would pose a problem for biological systems.”

Going forward, the group are centring their research on enhancing the stability of the hydrogenases at higher power densities.