Materize is an innovation platform designed to establish a single point of contact between scientists and industry.

In 2018, the Institute of Solid State Physics at the University of Latvia (ISSP UL) – the internationally-recognised leader in the materials sciences and cross-disciplinary topics in the Baltic States – created Materize. This is an industry collaboration innovation platform designed to establish a single point of contact where science can be beneficial to business and which also provides access to both the expertise and resources of the ISSP UL.

Olga Bogdanova, Materize Sales Director, said: “There is no point in science without real-world use. Everything we do is targeted to connect clients with science and ensure we help to resolve all issues they are struggling with along the way.”

By drawing on the experience of ISSP UL, Materize works alongside industry to develop internationally competitive research innovations in the fields of thin films, electronics, light emitters, fibre optics, sensors, and photonics which have applications ranging from ICT to energy harvesting.

Countless varieties of functional coatings

Functional coatings are the area in which the most requests for co-operation are received. From the standpoint of modern technologies, innovative functional coatings have the potential to include novel and unexpected properties which can be achieved during the modern manufacturing process. For example, various types of coatings can be antireflective, electroconductive, have low heat conductivity, and be electrochromic, and they play an increasing role in energy effective applications, solar panels, smart windows, indicators, and so on.

Historically, ISSP UL has a deep legacy in this research direction and there is now a wide and rapidly growing industry in this field which is serving to create a productive ecosystem of companies, start-ups, technology developers, and researchers. Materize has thus collaborated with world-leading coating developers, as well as start-up companies with fresh and ambitious ideas. Companies from completely separate fields have found Materize equipment and expertise useful for their innovations.

Co-operation partners

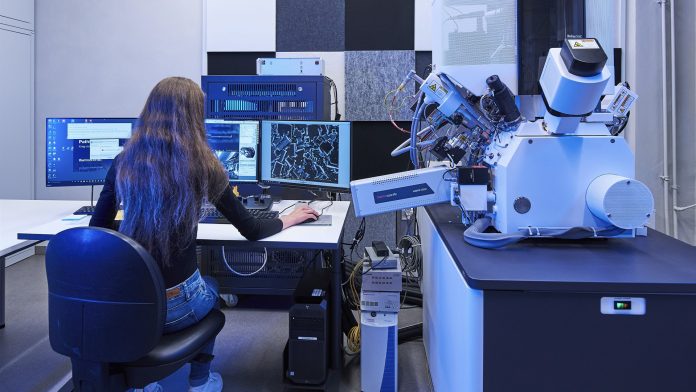

One of Materize’s close co-operation partners is a company called Groglass – one of the world’s leading developers and manufacturers of anti-reflective and other high-performance coatings on glass and acrylic for various industries. When Groglass develops new product, they turn to Materize’s experts to jointly design and test the special coatings. During their research projects, different coating materials have been tested by using TEM, SEM, and XPS methods.

“For us, the most important elements are speed, availability, and access to laboratory/measurement equipment in co-operation with a research institute. In business, one must react quickly and with as much information as possible,” Janis Zemitis, Head of Research and Development in Groglass, said.

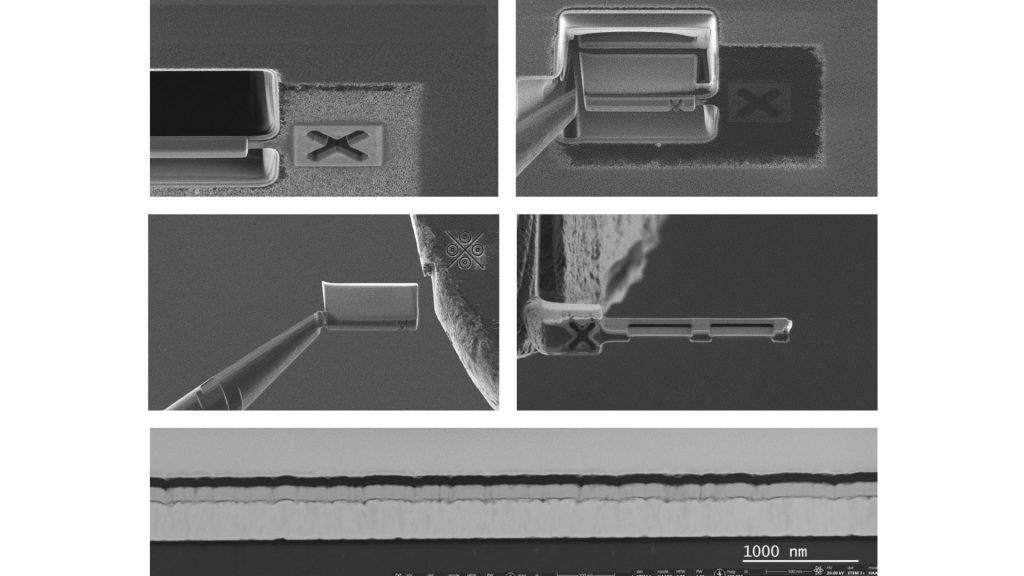

Dr phys. Krisjanis Smits, Leading Researcher and Head of Laboratory of Materials Morphology and Structure Investigations, added: “It is now necessary to look not only at the surface of a sample but also inside of a material, and we employ several methods to achieve this. The most common of these is lamella production for scanning/transmission electron microscopy (S/TEM). Such sample preparation for S/TEM analysis is considered to be one of the most critical but challenging and time-consuming tasks in materials characterisation laboratories. The successful analysis of a thin films in S/TEM requires very thin homogeneous lamella windows of the material to be fabricated. With our newest equipment (ThermoScientific Helios 5 UX), automation software for sample preparation, and well-trained staff, we can obtain the highest quality samples.”

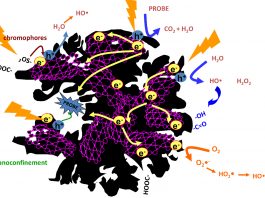

Naco Technologies, a company that works in the field of renewables and hydrogen energetics, is engaged in developing multi-layer, multi-component coatings for batteries, fuel cells, and electrolysers. The company collaborates with Materize to create SPEEK proton exchange membranes and to test their developed catalyst on it. The original structure and qualities of the samples are evaluated by using electrical impedance spectroscopy (EIS), scanning electron microscopy (SEM), thermal analysis (TA), and X-ray diffractometry (XRD). The results were interesting for both sides; the created membrane with catalyst coating has qualities which will help to differentiate the developed product in the market.

Pavels Nazarovs, a PVD Specialist at Naco Technologies, commented: “Close collaboration between private companies and research institutions is necessary as most emerging technologies and new products require an ever deeper understanding of underlying processes and nature. Companies cannot continue technological progress by relying solely on the resources of their internal R&D departments. That is why the availability of research institutions is so important – to provide additional resources and attract the minds of the best specialists in the field.”

Indeed, Naco Technologies and Materize have a constructive and excellent collaboration through several projects. Nazarovs added: “We are glad that a convenient platform for collaboration with research facilities has finally appeared in Latvia – Materize – through which it is possible to quickly and easily involve specialists, scientists, and high-precision laboratory equipment in the product development and search for new solutions.”

Infrastructure, know-how, and much more

By leveraging a recently-developed nanofabrication facility, Materize enables the development of various prototypes and devices from organ-on-a-chip solutions (and other microfluidics devices) to a polymer photonic platform. In collaboration with medical scientists and biologists, organ-on-a-chip technology allows cells to be grown in microreactors that are very well suited for drug testing and life science research.

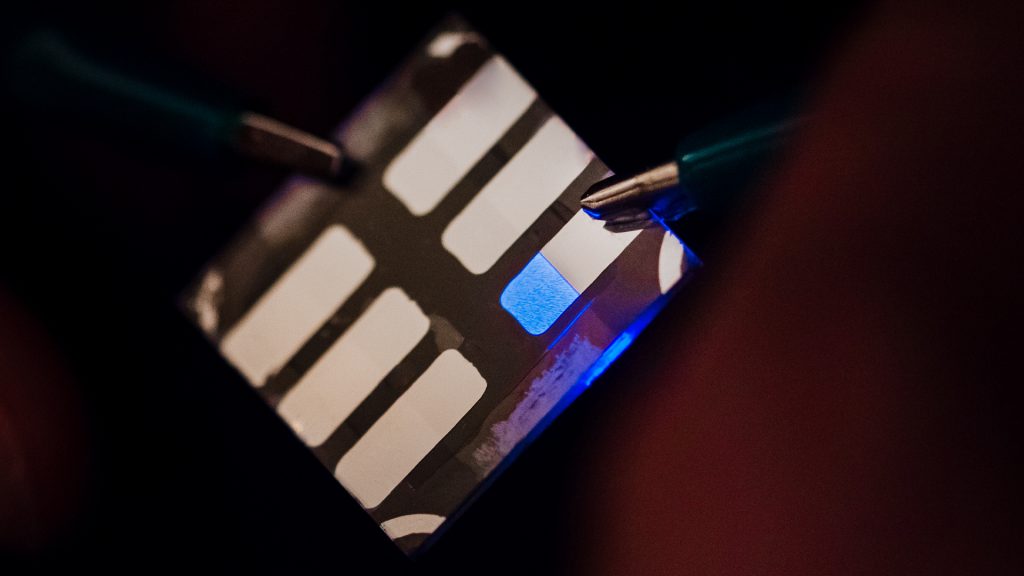

Materize also benefits from a high competence level in the field of organic materials. This includes both original material development as well as technical possibilities to fabricate devices and prototypes for various applications. This knowhow has led to numerous OLED and sensor development projects.

Dr phys. Aivars Vembris, Head of Laboratory of Organic Materials, added: “We perform full cycle development for OLEDs to create the most optimal design or material. We have all the necessary coating, patterning and characterisation equipment to create and test OLEDs, LEECs, and photovoltaic, as well as OFET devices or components.

Energy harvesting and storage

The energy harvesting and storage field is covered from battery materials to materials for hydrogen production, storage, and chemical conversion.

Materize’s international and co-operative research continues across other renewable energy sources and sustainable energy storage technologies with a lower environmental footprint, including thermoelectric and advanced functional and constructive materials for thermonuclear fusion.

An easily accessible science and innovation platform

Materize will find a way to make an idea a reality by involving a specially-formed team of scientists from relevant fields. An easy access to modern infrastructure, well equipped nanofabrication facility based on 650m2 ISO class 7-8 cleanroom, as well the know-how which has been accumulated over a period in excess of 40 years, provide an excellent environment for brilliant innovations.

Dr phys. Andris Anspoks, Materize General Manager, said: “In recent years a lot of effort has been devoted to creating an easily accessible science and innovation platform for our partners. We not only wanted to become more open for local and international companies, but also to become more open inside of the Institute. We have therefore applied an open access laboratory concept together with a laboratory information management system, which allows transparent access to all lab equipment and devices for ISSP UL researchers and external users, including industry. In today’s world, all projects have become increasingly multi-disciplinary and so require a more flexible approach.”

It is no secret that scientists and entrepreneurs see things in different ways. Materize connects both worlds and allows them to collaborate in the most efficient way.

“It is easy to work with Materize – they have a fast response time and open communication,” said Zemitis.

Throughout any given project, the client is supported by a business-oriented manager – from conceiving the idea right through to the complex scientific solutions. “The ‘one-point contact’ model works really well for start-ups because entrepreneurs do not need to know every leading expert in all areas personally. You just need to formulate the problem you want to solve and Materize will find the necessary specialists themselves and prepare the results in a layman-friendly way,” explained Nazarovs.

Latvia – business playground for innovative ideas

This Baltic country has a rich history in the field of high-tech development. Indeed, with one of the world’s fastest Internet connections, the largest airport in the Baltics with more than 100 flight connections, a beneficial geographical location, talent in STEM subjects – many of whom are able to speak multiple languages, a fast growing start-up community with a diverse range of investment opportunities, and optimised financial support, Latvia offers an excellent environment for innovation development.

Photonics and smart materials is a field that is highly significant for the Latvian economy, with many globally-recognised high-tech companies with market-leading products calling the country home.

An active and developing industry is at the core of sustainable evolution, and by involving scientific institutions and universities, as well as by receiving support from the government – the Ministry of Economics and the Ministry of Education and Science – it all connects together as an effective ecosystem.

The photonics and smart materials ecosystems have been formed in order to establish a joint state-supported development plan for this industry in addition to creating synergy via co-operation between institutions. The entire region will benefit from this ecosystem as there will be young, well-educated people and research projects in this field which will allow new products to be developed, additional work places, and economic growth.

These activities are supported by the ISSP UL’s Horizon 2020 Teaming project CAMART², which, as one of the largest projects in Latvian science, received European Commission funding for strategic development in assistance of the top players in the field from Sweden – Royal Institute of Technologies (KTH) and Research Institutes of Sweden (RISE).

The project’s objective is to strengthen the ISSP UL’s position as a significant regional science, innovation, and technology transfer centre as well as to strengthen the position of the Latvian state within both Europe and internationally.

Olga Bogdanova

Materize Sales Director

+371 29 585 967

olga.bogdanova@materize.com

Tweet @materize

www.linkedin.com/company/materize

www.materize.com

Please note, this article will also appear in the seventh edition of our quarterly publication.