The Pneumatically Stabilised Platform (PSP) system permits the design and construction of very large floating platforms of unlimited size.

Today, aquaculture has its problems – ranging from raised fish escaping, to the oceans increasing temperatures. Worldwide, oceans absorb excess heat that is generated by greenhouse gas emissions, leading to rising ocean temperatures.1 As a result, both marine life and the ecosystem are adversely affected, alongside damaging previous advantages the ocean creates for humans (such as the cause of extreme weather conditions).1

Another current problem in aquaculture are raised fish escaping into oceans. When some fish are being raised, they are kept in pens or ponds that are connected to natural waterbodies. However, a downside to this method is that some of the fish can end up escaping. As a result, there are numerous consequences. Firstly, escaped fish can impact wild populations in terms of competing with them for food, habitat and spawning partners.2 Secondly, “most farmed species are distinctly different than their wild cousins. If escapees breed with their wild counterparts, the genetic makeup of their offspring may be less suited to surviving and thriving in the wild. In addition, fish are sometimes farmed in areas they are not native to. If they escape, they can establish themselves as invasive species and disrupt the harmony of the ecosystem”.2

Healthier feed = healthier fish

The process of analysis and oxygenation of sea/ocean water from deep depths should be the primary response to controlling and correcting the above predominant difficulties. However, controlled and contained aquaculture processes will assist wild fish growth by not interfering with the wind fish living cycle. Offshore aquaculture controlled and contained environments will primarily provide isolation, environment control, and containment. Increased water velocity within the containment cylinders will provide a healthier environment which will result in an expanded growth pattern.

This can be achieved with hatcheries, nurseries, growth tanks, and raising tanks as these devices isolate aquaculture raised fish from escaping. As a result, this ensures that there is absolutely no mixture or contamination with wild fish. In short, water testing and treatment is similar to water purification systems producing potable water for human consumption. However, the difference is that the water will be as identical as possible to the natural water environment for the fish during their various growth and raising cycles.

In addition to this, farmed salmon need eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) in their feed to ensure optimal growth, health and survival of the fish.3 Both of these aforementioned acids are long-chain omega-3 polyunsaturated fatty acids that can be found in fish and a variety of algae.3 Veramaris algal oil contains the highest, stable concentration of both EPA and DHA available on the market today, which means that nutritionists can rely on this ingredient to support optimal fish health. With a high focus on the welfare of farmed fish, nutritionists want to ensure that biological functions, health and development are taken good care of.

Aquaculture controlled and contained systems

In order to provide a controlled and contained environment, Float Europe systems provide the following:

- Cylinder sizes are designed for intended sale size(s) of fish;

- Containment tank(s) are cleaned of all waste prior to replacing existing water

- Containment tank(s) waste are recycled in order to obtain solid residue that can then be sold on as agricultural fertiliser

- Deep ocean water is drawn, filtered, and oxygenated prior to pumping into containment tank(s)

- On-board hatchery, smelt raising tanks

- On-board fish processing plant for packing and shipment (vessel berthing piers available) leeward, and

- Crew accommodation facilities included on board platform.

Aquaculture and Containment Project Rationale

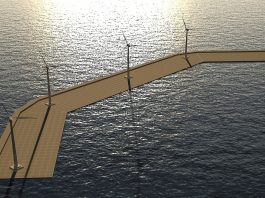

The industrial-scale aquaculture required to domestically supply the large and growing demand for seafood will be enabled by the availability of suitable offshore floating platforms. These platforms must be large, stable, long lived and environmentally neutral, such platforms must also be economic to construct, to maintain and to operate upon. Floating platforms with the desired characteristics may be obtained utilising the Float Inc. Pneumatically Stabilised Platform (PSP) technology developed with the support of DARPA and ONR.

Large area, motion stability in ocean waves, and very large variable deck load capacity are characteristics specific to the PSP, and to no other floating platform concept. The platform is designed for the environmental conditions of each candidate and their individual site specifics. In addition to this, modularly constructed in reinforced, pre-stressed concrete, the PSP is essentially immune to corrosion. As a result, the platform requires very little maintenance (for example, no dry-docking is necessary), and has very long service life). Unit costs, in dollars-per-acre, decrease with PSP size, while motion stability and utility increase. At the same time, there currently appears to be no limit to the potential size of the PSP.

The floating platform will deploy very efficient wave energy harvesters of the broad-band multi-resonant ‘Oscillating Water Column’ (OWC) type. Where available, wave energy is somewhat limited (±15kW/m, average). Alongside this, with large horizontal dimensions of aperture, these converters are capable of supplying all of the energy needs of the platform and its operations. Similarly, to the PSP, the OWCs are built of reinforced concrete with all equipment in-the-dry, easily accessible for maintenance by dry-shod workers. The supporting PSP will also provide excess energy storage by means of its pressurised air variable buoyancy.

Aquaculture enclosed fish growing tanks

The breakwater effectiveness of the PSP will be enhanced by the action of the wave absorbers arrayed across its wind/wave sides. This in turn, ensures minimal water motion on the leeward side, providing a calm lee for the docking and offloading of supply ships. Their cargo, mainly many tons of feed, will be moved by crane, conveyer and/or trucks to and from storage “silos” within the platform structure. There is expected to be fish hatchery and raising pens enclosed within the protective zones of the PSP/Rho-Cee WEC design. Additionally, a raised fish processing plant is also expected to be included with the protective zones of the PSP/Rho-Cee WEC design. The fish growing pens (containment tanks) will be serviced by gantry cranes that span them.

The floating platform is pre-designed to house, feed and care for a crew of farm, maintenance and supervisory personnel on a two-weeks-on, two-weeks-ashore basis – just as in the offshore oil and gas business. Moreover, because of the plastic waste and toxins that are found in today’s seas/oceans, Float Europa propose aquaculture “enclosed fish growing tank(s)” that are ventilated with filtered ocean water from depths of -100 meters and oxygenated before pumping into enclosed raising pen(s).

Getting to know the PSP system

The Pneumatically Stabilised Platform (PSP) system permits the design and construction of very large floating platforms of unlimited size. PSPs may be deployed in regions with extreme wave heights and achieve more stability than achieved by any other known marine technology. The PSP is a patented design concept for large floating platforms, in which the flotation force is derived from an array of open-bottom cylinders retaining pressurised air that displaces the water. As the Pneumatically Stabilized Platform is buoyantly supported afloat in large measure by pressurised air, and the accessible internal volume of a PSP platform is quite large, considerable potential energy can be stored. That energy can later be recuperated during intervals of low wave activity to better match varying demands of the electrical load infrastructure demands.

Some of the PSPs key characteristics are:

- Softer response to waves with higher deck load capacities

- More than 70-years of longevity without significant maintenance

- Deployable in unlimited water depth and of unlimited platform size

- Supports multiple energy sources (including wave, wind, and current)

- Supports multiple functions (such as lodging, dining, medical facilities, and maintenance facilities for turbine, rotor and boat repairs) and

- Provides protected calm waters (leeward) for supply ship and maintenance craft dockage.

References

- https://www.iucn.org/resources/issues-briefs/ocean-warming

- https://www.seafoodwatch.org/ocean-issues/aquaculture/escapes

- https://goedomega3.com/about-epa-and-dha

Franklin Martin

Managing Director

Float Marine Technologies Europe Ltd

+33 493 378 543

contact@floateurope.eu

http://floateurope.eu/

Please note, this article will also appear in the first edition of our brand new quarterly publication. Subscribe to our updates for free here.