A team of scientists have invented a novel lightweight aerogel material that may potentially advance the next generation of aircraft, reducing noise and enhancing comfort.

The new aerogel material, developed by researchers from the University of Bath, is the lightest sound insulation that has ever been manufactured – an exceedingly lightweight substance that is proficient in mitigating engine noise from an aircraft whilst simultaneously improving the comfort of the passengers on board.

Their research findings are published in the journal Scientific Reports.

The scientists generated a graphene oxide-polyvinyl alcohol aerogel that weighs in at a mere 2.1kg per cubic metre – officially making it the lightest sound insulation ever produced – with the ability to reduce the noise of aircraft engines by up to 16 decibels. Incredibly, this means that the colossal roar of a jet engine during taking off will be decreased from 105 decibels to closer to that of a hairdryer.

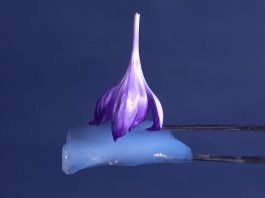

The aerogel consists of a meringue-like structure, making it exceptionally light, perfect qualities for acting as an insulator within the nacelles of an aircraft engine, adding practically no overall weight in the process. The researchers are now conducted further refinements of the aerogel material to improve heat dissipation, safety, and fuel efficiency.

Professor Michele Meo, the leader of the research, said: “This is clearly a very exciting material that could be applied in a number of ways – initially in aerospace but potentially in many other fields such as automotive and marine transport, as well as in building and construction.

“We managed to produce such an extremely low density by using a liquid combination of graphene oxide and a polymer, which are formed with whipped air bubbles and freeze-casted. On a very basic level, the technique can be compared with whipping egg whites to create meringues – it’s solid but contains a lot of air, so there is no weight or efficiency penalty to achieve big improvements in comfort and noise.”

From the outset, the primary focus of the team was to collaborate with partners in the aerospace industry to test the aerogel in aeroplane engines as a sound insulator; however, they believe the end result could well be utilised in helicopter panels and car engines, with the scientist optimistic that the material could be seen in use within 18 months.