Champaign-Urbana Aerospace (CUA) aims to identify, develop, and distribute promising new commercial aerospace technologies.

Founded in 1998, CUA’s 10,000 sq ft mixed laboratory/office facility is located in northwest Champaign, Illinois, USA. The facility contains an ISO7 cleanroom, a rapid prototyping shop, and five laboratories: Spacecraft Propulsion Lab, Plasmadynamics Lab, Spacecraft Mechanisms Lab, Advanced Materials Lab, and High Performance Computing/Astrodynamics Lab.

Spacecraft Propulsion

CUA has developed six innovative micropropulsion technologies for integration and flight on micro/nanosatellites. This family of systems provides a broad range of capabilities from high thrust to high specific impulse to best suit customer needs.

The Propulsion Unit for CubeSats (PUC) utilises a micro-plasma discharge thruster for a highly compact warm gas system. The CubeSat High-Impulse Propulsion System (CHIPS) utilises a micro-resistojet warm-gas thruster combined with attitude control thrusters to provide a versatile multiaxis package. To dramatically lower system cost, CUA has now developed two polymer-based fibre propellant systems in which the fibre is stored and fed from a simple spool. The Monofilament Vaporisation Propulsion (MVP) system uses 3D printing technologies to feed and melt the fibre followed by the CHIPS micro-resistojet that vaporises the melted fibre and produces thrust. The Fibre-fed Pulsed Plasma Thruster (FPPT) takes advantage of modern electronics technologies to enable compact packaging to produce thrust with high specific impulse of 3500 seconds. The fifth propulsion technology being developed is a high thrust option using an ethanol/peroxide mixture. This monopropellant, designated CMP-X, is a non-detonable yet energetic formulation that possesses many system-level advantages including lower cost, common materials compatibility, lower thermal load and soakback into the spacecraft. The sixth propulsion technology is the Cycle Automated Mass Flow (CAMFlow) system, providing reliable and well-regulated flow control for electric propulsion systems, particularly well-suited for the low flow rates required by sub-kiloWatt Hall effect thrusters.

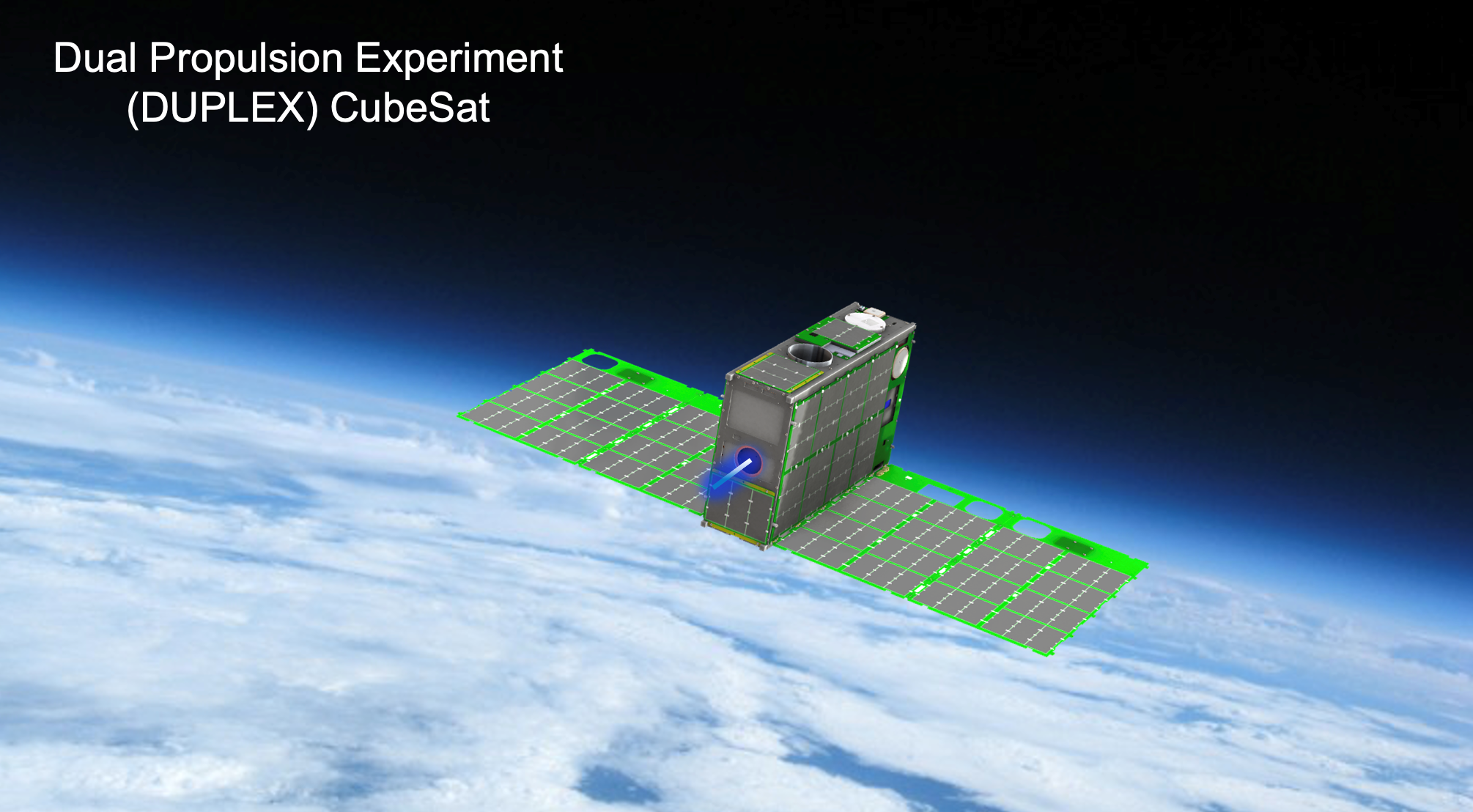

CUA received NASA STMD Tipping Point funding for the design, fabrication, launch and in-space demonstration of the Dual Propulsion Experiment (DUPLEX) CubeSat. DUPLEX will test CUA’s innovative FPPT and MVP thruster systems and provide flight heritage to lower risk for future customers and increase commercialisation potential. Launch of the DUPLEX spacecraft is manifested in the third quarter of 2022.

GRASP

The Guideless Resilient Androgynous Serial Port (GRASP) mechanism provides an androgynous mechanical and electrical interface that can be tailored to meet the requirements of a given application. Developed for modular spacecraft assembly, though extendable to ground-based robotic systems, each assembly mechanism is equipped with physical connections for both power and data transmission between the different modules.

Spacecraft Software

The Dynamically Leveraged Automated (N) Multibody (DyLAN) Trajectory Optimisation tool is an automated global trajectory optimisation software package for rapid preliminary mission design of impulsive/low-thrust multibody missions. DyLAN provides engineers with an automated tool that can provide multi-objective solution sets, enabling new design concepts and tractable solutions for currently ‘unsolvable’ problems.

CUA’s sister optimisation tools NLPAROPT and COMPNOT for distributed and shared memory computer architectures, respectively, are parallelised non-linear programming (NLP) optimisation solvers that eliminate the bottleneck of existing serial execution NLP solvers.

The SEPTER software tool utilises genetic algorithm (GA) approaches to determine optimal configurations of modular spacecraft architectures based on mission requirements.

Other

The THERMOSYS™ toolbox is a suite of simulation tools for analysing the behaviour of air-conditioning and refrigeration systems (both steady-state and time-dependent) including electrothermal component modules.

VascTech™ sacrificial materials are high strength fibres, extruded sheets, and filaments for 3D printers. VascTech has been used to create efficient microvascular composite heat exchangers and other complex components.

AREAS OF EXPERTISE

- Propulsion

- Spacecraft Systems and Mission Design

- Plasmadynamics

- Advanced Materials

- Aircraft Safety

- Modelling and Simulation

- High Energy Lasers

RESEARCH INTERESTS

- Micropropulsion, Electric Propulsion, Monopropellants, and Solar Sails

- Spacecraft Assembly and Distributed Sensing Systems

- Spacecraft Trajectory Optimisation and Design

- Plasma Flow Control, Plasma Assisted Combustion, and Plasma Sterilisation

- Sacrificial and Self-Healing Materials

- Aircraft Icing Mitigation

- Multiphysics and Electrothermal Modelling and Simulation

- Gas Discharge, Chemical, and Alkali Lasers