With over 20 years of focused R&D in high-temperature superconductor applications, HTS-110 designs and manufactures cryogen-free magnet systems for advanced research, industrial QA, and next-generation fusion prototypes.

Established in 2004, HTS-110 is a pioneering company specialising in high-temperature superconducting (HTS) magnets for x-ray and neutron beamlines, magneto-optical studies, and superconductor wire characterisation.

Drawing on decades of R&D into cuprate superconductors (discovered nearly 40 years ago), our team has helped redefine the possibilities of magnet design by exploiting HTS’s ability to achieve higher fields at more accessible temperatures (20–60 K).

Capabilities of high-temperature superconductors

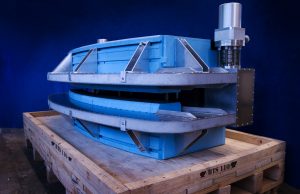

Our portfolio highlights cryogen-free fast-ramping and high-field electromagnets, HTS coils in circular, racetrack, or non-planar forms, and HTS current leads for thermally efficient power transfer.

We have also delivered advanced 9.4T dry NMR magnets, the first to demonstrate high-resolution spectroscopy without liquid helium. In addition, we produce 12T split-pair magnets for a instrument designed from the ground-up for superconductor characterisation, creating a benchmark for wire QA in the fusion industry.

This creates a benchmark for wire QA in the fusion industry.

Fusion: The next frontier

HTS’s capacity for higher fields is the main driver behind smaller footprints in magnetically confined fusion, while its elevated operating temperature and robust thermal stability amplify this benefit with simplified cryogenics compared to low-temperature superconductors.

Recognising this, these key product lines directly support compact fusion development:

- CryoSaver™ current leads, minimising conduction losses.

- CryoForge™ coils, adaptable to any geometry, including ReBCO options for even greater in-field performance.

- SuperCurrent instruments, automating critical current measurements and accelerating HTS wire QA.

- Custom magnet development for end-to-end fusion solutions, leveraging our deep HTS expertise to expedite the implementation pathway.

From design to delivery

At HTS-110, we manage every project stage—conductor selection, mechanical reinforcement, quench protection, and integration of cryocoolers—under one roof.

This holistic approach unites decades of HTS engineering, ensuring consistent quality and faster time to market for high-performance magnets.

Looking ahead, we remain committed to pushing boundaries in fusion and beyond, working with forward-thinking partners to harness HTS’s unrivalled potential for next-generation research and industrial applications.