The ANEMEL project is hastening the development of electrolysers capable of operating under low-grade water sources or saline water, targeting the EIC Challenge ‘Novel routes to green hydrogen production’.

The European Innovation Council (EIC), challenging the ANEMEL project, is a groundbreaking programme within the European Commission’s funding strategy strategically designed to catalyse innovation. At its core, the EIC seeks to identify, develop, and scale up breakthrough technologies that are pivotal for the progress of European society and its economy.

One of the noteworthy initiatives within the EIC is the Green Hydrogen Challenge portfolio, consisting of nine collaborative projects united by a shared objective – to pioneer more efficient and sustainable methods for hydrogen production.

This collective effort aims to position Europe at the forefront of the hydrogen economy, diminishing reliance on fossil fuels and propelling the continent towards a climate-neutral future.

Innovative collaborating networks

Among the projects collaborating under the EU’s Green Hydrogen Challenge, the ANEMEL project plays a vital role alongside other innovators.

The collaborative efforts include:

- H2STEEL: Focused on developing cost-competitive sustainable steel using green hydrogen and bio-coal;

- PhotoSynH2: Exploring new technologies for green hydrogen production from solar energy through biological systems;

- ELOBIO: Engaged in the manufacture of green hydrogen from biomass;

- DualFlow: Innovating flow technologies for green hydrogen production and efficient batteries;

- MacGhyver: Integrating microfluidics and electrochemistry to treat wastewater and simultaneously produce green hydrogen;

- EPOCH: Dedicated to producing hydrogen carriers and chemicals from lignin;

- GH2: Focused on green hydrogen production from water and bioalcohols; and

- OPHERA: Pioneering photoelectrochemical production of green hydrogen.

These projects, along with the ANEMEL project, form the pioneering EIC Hydrogen Portfolio, where researchers and innovators collaborate to share results, insights, and data.

This collaborative environment aims to elevate these innovative technologies’ Technology Readiness Level (TRL), facilitating their transition towards tangible business opportunities. The collective pursuit of these projects aligns with the overarching mission of the EIC to drive transformative advancements and position Europe as a global leader in sustainable innovation.

Project structure

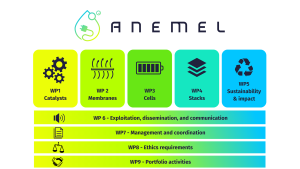

The ANEMEL project is meticulously structured into nine distinct work packages (WPs), each playing a pivotal role in advancing the development of green hydrogen technology.

WP1

Here, the focus lies on the design of catalysts intended to expedite the water-splitting process, with a crucial objective of replacing rare metals with sustainable alternatives.

WP2

This is dedicated to developing semipermeable membranes, steering away from critical and contaminant raw materials to ensure efficiency and sustainability.

WP3

This combines electrocatalysts and membranes seamlessly for efficient cell assembly, rigorously testing different configurations to pave the way for successful scale-up.

WP4

Here, the emphasis is on building stacks for real-life testing, with a lofty goal of achieving non-stop operation for over 2000 hours, demonstrating durability and stability.

WP5

Sustainability takes centre stage, focusing on an eco-friendly design ethos. This involves conducting a comprehensive life cycle analysis (LCA) to ascertain a minimal environmental impact throughout the project’s lifecycle.

WP6

This part of the ANEMEL project undertakes the responsibility of communication and exploitation, ensuring that the project’s goals and results are effectively communicated to society while actively encouraging industry incorporation for sustained, long-term impact.

WP7

This handles the critical management task, meticulously coordinating collaboration among project partners and with the European Commission to ensure the alignment of efforts with project objectives.

WP8

This delves into the ethical impacts and implications of the research, innovation, and exploitation processes.

WP9

Known as Portfolio Activities, it is the nexus for managing collaboration between projects funded by the European Innovation Council (EIC). This work package is dedicated to maximising the societal impact of these collaborative endeavours, underscoring the collective commitment to driving positive change and innovation in the pursuit of sustainable green hydrogen technology.

Aims of the ANEMEL project

The ANEMEL project seeks to carry out the following objectives:

- Proof-of-concept or lab-scale validated green hydrogen production;

- Focus on electrochemical water splitting with AEMWE technology for increased lifetime and reliability;

- To design, operate, and validate a 1 kWe stack committed to long-term testing;

- Utilise abundant non-PGM materials (Ni, Fe, Mn, SS stainless steel, fluor-free polymers);

- Avoid dependence on critical raw materials like Pt, Ir, Ru, Ti, and Co;

- Emphasise low-cost electrolysis for a competitive advantage in the EU hydrogen industry;

- Full Life Cycle Analysis (LCA) to showcase reduced environmental impact over the hydrogen supply chain;

- Comprehensive assessment of environmental benefits, considering potential compromises;

- Explore O2 co-production benefits, including applications like wastewater BOD/COD reduction and hospital use;

- Integrate renewable power sources, demonstrating direct start-up and fast load change capabilities;

- Be compatible with diverse renewable profiles such as PV/wind and potential use of run-off-river hydropower;

- Improve performance metrics, targeting 2 V, 1 A/cm2 and low degradation rates;

- Demonstrate scale-up processes through collaborations with industry partners; and

- The ANEMEL project seeks to be a key player in advancing sustainable and efficient green hydrogen technology in line with the European Innovation Council’s Green Hydrogen Challenge.

ANEMEL project coordinator and beneficiary: Dr Pau Farras

ANEMEL is coordinated by the University of Galway’s Associate Profesor Pau Farras, head of the ChemLight research group at the School of Biological and Chemical Sciences.

The group specialises in harnessing visible light to facilitate chemical reactions, primarily focusing on synthesising and studying organometallic complexes, materials, and hybrid systems.

Their multidisciplinary research spans organic and inorganic synthesis, spectroscopy, electrochemistry, and catalysis, with applications in the fields of energy, health, and life.