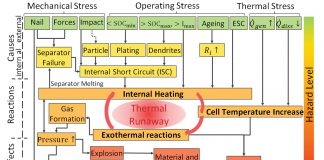

The development of safe lithium-ion cells is of utmost importance for a breakthrough in the electrification of transport and for stationary storage, because an uncontrollable increase in temperature of the entire system (the so-called ‘thermal runaway’) can cause an ignition or even explosion of the battery with the simultaneous release of toxic gases.

Thermal runaway

Thermal runaway is something that nobody wants, especially in an electric car or another electric vehicle; and the causes and effects of this can be very diverse and complex. As such, it is crucial to conduct thermodynamic studies of the thermal effects together with the material and cell development for advanced and even post-lithium systems.

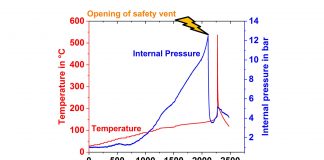

Battery calorimetry is very important as it is fundamental to obtaining quantitative data on the thermal behaviour – you need to know how many watts a cell will produce under certain conditions; and this can be investigated in the calorimetry tests. This information can then be used to adapt the battery and thermal management systems.

Sophisticated battery calorimetry combined with thermography allows new and quantitative correlations to be found between different critical safety and thermally related parameters.

The temperature, heat and internal pressure evolution can be studied, while operating cells under conditions of normal use, abuse or accidents. These data are essential for battery management, thermal management and safety system design. Combined with multi-scale electrochemical-thermal modelling they provide a powerful tool for thermal runaway prevention and ageing prediction.

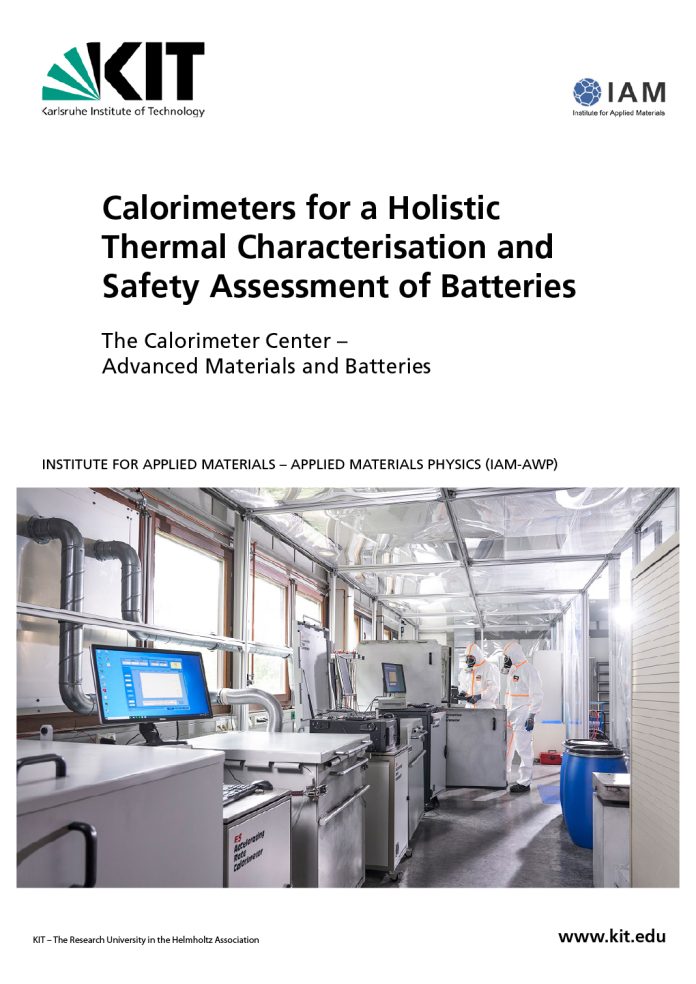

The Battery Calorimeter Center

Established in 2011, the Battery Calorimeter Center at the Karlsruhe Institute of Technology’s (KIT) Institute for Applied Materials – Applied Materials Physics now operates Europe’s largest battery calorimeter laboratory.

It provides six Accelerating Rate Calorimeters (ARCs) of different sizes – from coin to large pouch or prismatic automotive format – in combination with cyclers, which allow the evaluation of thermodynamic, thermal and safety data for lithium-ion cells on material, cell and pack level under adiabatic and isoperibolic environments for both normal and abuse conditions (thermal, electrical, mechanical).

With these facilities and the established technical and methodological expertise, the IAM-AWP is now – seen worldwide – one of the few institutions that investigate both the thermodynamics and the safety of batteries and their materials. The results of these investigations can be used on all levels of the value chain – from the safe design on materials level up to the thermal management and the adaptation of safety systems.

Our fields of research and range of tests encompass both normal conditions and abuse conditions.

EXPERTISE

Normal condition tests:

- Isoperibolic cycling measurements, which provide constant environmental temperatures;

- Adiabatic cycling measurements, which ensure that there is no heat exchange between the cell and the surroundings

Each of these allows:

- Measurement of temperature curve and distribution for full cycles, or application-specific load profiles;

- Determination of generated heat;

- Separation of heat in reversible and irreversible parts; and

- Ageing studies.

Abuse condition tests:

- Thermal abuse – heat-wait-seek, ramp heating and thermal propagation test;

- Electrical abuse – external short circuit, overcharge and overdischarge test; as well as

- Mechanical abuse – nail penetration test.

Each of these allows:

- Temperature measurement;

- External or internal pressure measurement;

- Gas collection;

- Post-mortem analysis; and

- Ageing studies – identifying the change of risk potential with increasing degree of ageing.

RESEARCH INTERESTS

- Separation of heat data into reversible and irreversible parts

- Establishment of the temperature profile as a ‘fingerprint’ for the state of health (SOH) and as a fast and reliable method for the characterisation of ageing processes of the materials in the cells

- Study of the influence of ageing phenomena on different modes of heat generation under normal use

- Correlation between temperature, pressure and impedance data of cells

- Development of safer cells by:

- Improving electrode materials, separators or electrolytes

- Ensuring of safe upscaling to larger cell formats

- Methods for early detection of processes leading to thermal runaway by combining sensors and simulation

- Standardised procedures to qualify suitable countermeasures for thermal propagation, such as heat protection barriers