With its new approach to permanent magnets, PM-Wire magnets, the Advanced Magnet Lab is enabling the use of lower-cost materials, novel design and manufacturing, and revolutionising motors and generators to decommoditise the magnet supply chain.

Magnets are at the heart of products like electrical machines (motors and generators), which are, in turn, used in virtually every sector of society – energy, manufacturing, consumer products, and transportation. Magnets are a critical component in areas like defence, used for instrumentation, weapons, and vehicles (land, air, and sea).

Today, China dominates the market, controlling over 85% of the magnet market. China’s vertical integration of cheap labour, raw materials, and unsafe environmental standards has resulted in a high barrier to market entry for competitors worldwide. Historically, companies entering the magnet market could not compete with China and sustain a magnet business.

The Advanced Magnet Lab (AML), Melbourne Florida, has taken a completely different approach. Breaking China’s stronghold requires breakthrough innovations for enabling a sustainable magnet supply chain to re-invent technology and transform the industry.

To do this, AML is innovating all aspects of the supply chain, including materials, magnets, magnet manufacturing, and the largest magnet market electrical machines. This new approach will result in a sustainable and decommoditised magnet supply chain.

The conventional approach to the magnet supply chain is wrong

While scale has increased and materials have improved, the materials used to make magnets, magnet technology, and the methods for manufacturing magnets and how the magnets are used in applications have been the same for decades.

Conventional magnets are complex to assemble and limit design engineers to configurations which are not optimised for performance and cost of the end-use products, such as electrical machines. Magnets are produced in blocks, then cut into small pieces, and sold as a commodity.

Conventional magnets are restricted in shape, size, and mostly single-direction magnetisation, meaning the largest market motors are limited to traditional north-south magnet pole designs. This requires dozens, hundreds, and sometimes thousands of magnets in an assembly. With very strong magnetic fields, assembly into a motor is complex and costly.

Furthermore, the trend is towards higher-grade and better-performing magnet alloy compositions, requiring expensive rare earth elements (REE) and an unclear intellectual property landscape.

The AML market approach

AML’s business model is to not make conventional ‘me-too’ magnets. Historically, companies entering the magnet supply chain could not compete and sustain their business due to China’s stronghold and ability to manipulate the market.

A magnet business can only be sustainable if the magnet product provides the magnet user with a better solution.

A solution that not only competes with but out-competes the conventional Chinese approach. AML’s approach to the market is unique. AML focuses on what matters. Improving the performance and lowering the cost of the end-use product.

The AML technical approach

Unlike the conventional approach, AML’s approach provides engineers with a whole new set of tools to enable fully optimised product designs. The approach can be used with existing sintered magnet alloys and opens new markets for non-sintered and non-REE alloys. Electrical machine designs can now be fully optimised for performance, including efficiency, torque, mass, operating temperature, and ease of assembly.

To do this, AML is addressing and therefore innovating every aspect of the magnet supply chain, which will result in a decommoditised market. This includes the magnets, magnet materials, magnet manufacturing, and electrical machines.

PM-Wire magnets

AML has developed and patented a manufacturing process for sintered, non-sintered, and non-REE magnets called PM-Wire™. PM-Wire magnets are manufactured using a semi-continuous, high-yield and high-rate manufacturing process with flexibility in the magnet length, cross-section, magnet shape and magnetisation direction.

PM-Wire is the ideal way to produce magnets; it uses a ‘wire-like’ manufacturing process where all the critical process parameters can be adjusted and precisely maintained for any magnet alloy type, including non-REE materials.

The manufacturing process involves filling thin-walled tubes with permanent magnet alloy powder, powder densification, and applying a magnetic field with a preferred direction of magnetisation. The tube is then size reduced to its specified cross-sectional (i.e., square, rectangular, pie-shape), rolled into its final shape (i.e. straight, curved, rings, helixes), and then finally magnetised.

For non-sintered magnets, the tube becomes the magnet powder containment and a means to optimise the packing density which optimises the magnet performance. It also eliminates the need for a bonding agent, further optimising the performance. The tube becomes the magnet jacket, resulting in virtually an unbreakable magnet, and the jacket seals the magnet, preventing oxidation and corrosion.

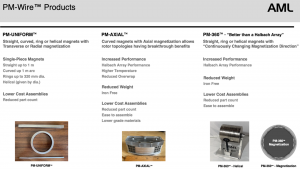

The PM-Wire product line currently includes three unique configurations, which are named based on the type of magnetisation direction: PM-UNIFORM™, PM-AXIAL™ and PM-360™.

PM-UNIFORM™

Consisting of straight, curved, ring, or helical magnets with transverse or radial magnetisation, these can be produced in metre lengths and offer lower cost assembly and reduced part count.

PM-AXIAL™

Curved magnets with axial magnetisation, allowing rotor topologies with breakthrough benefits. The PM-AXIAL provides increased performance, reduced mass, and ease of assembly for any given alloy or provides equivalent performance using lower grade/cost alloys, including non-REE alloys.

PM-360™

Straight, ring, or helical magnets with ‘continuously changing magnetisation direction’ (continuous Halbach array), PM-360 offers increased performance, significantly reduces part count, reduces mass, and greatly simplifies assembly. These can be produced in straight metre lengths, ring, or helical shapes and offer significantly lower cost assembly and part count.

The magnet alloys

The AML approach improves the application performance of all existing magnet alloys and enables the use of new, lower-cost alloys including REE-free alloys.

Today, REEs are an essential and critical aspect of the magnet supply chain. REEs are not rare at all; they are called rare due to the difficulties in extracting and separating the metals from the ore. These elements rarely exist in pure form; they are usually found mixed with other minerals, making them costly to extract into the pure form of REE oxides needed for magnets.

There are 17 REEs, with those categorised as the critical magnet REEs being neodymium, praseodymium, dysprosium, and terbium. Other non-critical REEs to be considered for magnets are lanthanum and cerium.

Magnet alloys and key performance drivers for electrical machines

Magnets are produced from alloys such as neodymium iron boron (NdFeB) which can have differing compositions based on a specific application requirement. An example NdFeB composition would include neodymium praseodymium (NdPr) (29%), iron (68%), boron (1.2%), aluminium (0.3%), niobium (0.5%), dysprosium (1%). The differing compositions result in magnet grades (i.e., N40, N40H, N45, N48SH).

The higher the grade, the greater the performance and the higher the cost. To understand the basics of a magnet grade and associated performance there are a few key parameters which strongly depend on temperature, the magnetic remanent field (Br), coercivity (Hc) and energy product (MGOe). For example, NdFeB N48SH has a Br of 1.2 tesla, Hc of 8.1 kGauss (kG) and an energy product of 36 MGOe at 120°C.

A key performance driver for electrical machines is coercivity which, unfortunately, decreases with increasing temperature. Coercivity in a magnet determines the degree to which a magnet can withstand an external magnetic field opposing its magnetisation without becoming demagnetised.

PM–Wire magnets can reduce the critical REE content in electrical machines

While the magnet industry continues in the direction of higher Br, Hc, and MGOe, PM–Wire enables alloys to go in the opposite direction. As a result, the use of magnet alloy compositions with lower critical REE content or no REE is now possible. For example, an inexpensive alloy called mischmetal (Mm) can replace part of the NdPr in NdFeB magnets, which can reduce the amount of critical REEs from 20-70%.

Mm contains NdPr and other non-critical REEs like lanthanum and cerium, which reduce the magnet coercivity, making them unusable for electrical machine applications that use conventional magnet configurations.

Examples of non-REE magnet alloys are manganese bismuth (MnBi), which presents a low Br but high Hc which uniquely increases with temperature, and iron nitride (FeN), which has a low Hc. Both do not require an expensive sintering process.

Breakthrough magnet technology for lower cost alloys

PM–Wire magnets enables the use of low Hc alloys in high performance motors and generators. One example is an industrial motor which uses conventional north-south motor topology and high-grade N48SH NdFeB alloy having an Hc of 12.5kG at 80°C.

Using PM–AXIAL, AML can achieve the equivalent performance using Mm and FeN magnets, which have a coercivity of only 3.5kG at the same temperature. Other examples of uses for PM–AXIAL are for electric vehicle motors where the NdFeB is replaced with non-REE FeN alloy and exceeds the U.S. Department of Energy’s power density goals of 50 kW/L.

PM-Wire enables non-sintered alloys for electrical machines

Another advantage of PM–Wire’s impact on alloys is enabling the use of non-sintered magnets. Non-sintered alloys include NdFeB (A.K.A. anisotropic bonded), MnBi, FeN, and samarium iron nitride (SmFeN). Eliminating the process of sintering significantly reduces the equipment, processing, and labour needed for manufacturing magnets.

However, non-sintered magnets have a lower Br as compared to sintered magnets. PM-Wire enables non-sintered magnets due to three unique features: for manufacturing, it provides an ideal method to densify and contain the alloy into a virtually unbreakable magnet without a bonding agent. This optimises the performance of any non-sintered alloy allowing for higher compaction to be achieved.

Secondly, magnetised and shaped as a PM-360 magnet, it can compete with higher grade, higher Br sintered magnet alloys in conventional north-south magnet pole configurations.

Finally, these magnets have higher resistivity than sintered magnets, which reduces the problematic eddy currents in permanent magnet rotors, which hinder performance and can significantly increase the part count and require active cooling.

The AML Impact

Replacing conventional magnets with PM-Wire significantly improves the performance and lowers the cost of magnet-based applications such as electrical machines (motors and generators). The following are real-world examples showcasing the potential impact of PM-Wire magnets:

Magnet manufacturing

AML prides itself on its novel and state-of-the-art manufacturing. Highly automated, it provides high-rate, high-yield, high-quality, ideal magnetisation, and at a much lower capital cost than conventional manufacturing methods. AML has developed its first production line for non-sintered PM-Wire magnets. The innovative line is capable of producing ~4m of linear magnets per minute. In 2024, AML will commission its first production line for sintered magnets. These programs were funded by the U.S. Department of Defense.

To understand production capacity using the PM-Wire’s manufacturing approach, it is best represented by using the California Mountain Pass rare earth mine deposit. This deposit, having an expected production capacity of over 6,000mtpa of NdPr REE, would yield over 20,000mtpa of finished magnets.

Using conservative manufacturing production parameters, only 7-25 production lines (depending on magnet cross-section) would be needed to produce straight non-sintered PM-Wire.

For sintered magnets, this same manufacturing process is used for sizing and shaping. The additional steps for sintering, final sizing, and coating is the same as for all manufacturers of sintered magnets. To put this in perspective, there are magnet manufacturing plants being constructed outside of China which require tens of thousands of square metres to produce 1,000mtpa of magnets.

Revolutionising electrical machines

PM-Wire magnets can replace conventional north-south topologies with optimised magnet shapes, magnetisation, and topologies which result in improving the performance and lowering the cost of the end-use product, such as electrical machines.

PM-Wire allows for optimising every aspect of the magnets used in electrical machines, the materials, shapes, magnetisation, and motor topology. Below are real-world examples which showcase PM-Wire’s high-impact enabling features and benefits:

Electric vehicle motor using non-sintered alloy

In a collaboration with the U.S. Department of Energy’s Oak Ridge National Laboratory, AML’s solution using PM-360 motor topology replaces 2,750 Halbach arranged sintered magnets with eight PM-360 non-sintered helical magnets and eliminates the need to actively cool the motor rotor. As a result, AML’s solution is a fraction of the cost compared to the conventional solutions.

Electric vehicle motor with no critical rare-earth elements

The holy grail would be to eliminate REEs in electrical machines. Unfortunately, alloys like manganese bismuth (MnBi) and iron nitride (FeN) suffer in performance due to low Hc. As described above, AML’s PM-AXIAL enables low Hc alloys which can compete with the high-grade alloys used in sintered magnets.

Not only are MnBi and FeN free of REE, but both alloys do not require the expensive process of sintering. One example is a design for a large drive train electric vehicle. Using generation one iron nitride, AML can far exceed the U.S. Department of Energy’s goals for motor power density of 50kW/L.

Industrial motors using the same alloy with significant improvement in performance

Using the same magnet N48SH NdFeB alloy, AML’s solution significantly improves performance by replacing north-south pole topology with PM-AXIAL for a 375kW/11,000 RPM industrial motor. The configuration provides Halbach array performance, a 50% reduction in rotor overwrap thickness, further increasing performance, and a 20% increase in operating temperature and reduction in mass by removing the iron. This is a rotor retrofit with no change to the motor stator. Modification of the motor stator would result in an additional increase in performance.

Industrial motor using reduced critical rare earth alloy

For the same industrial motor and equivalent performance, an AML rotor retrofit uses mischmetal NdFeB alloy reducing the critical REE (NdPr and Dysprosium) content by 37% and an 11% reduction in active mass.

Industrial motors with reduced content of critical rare-earth elements

For the same industrial motor and equivalent performance, an AML rotor retrofit uses a non-sintered NdFeB alloy, reducing the active mass by 10%.

The AML process – Going from conventional to state-of-the-art

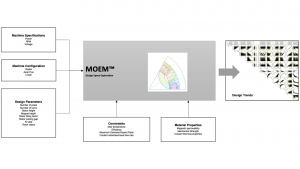

AML utilises proprietary software called MOEM™ and electrical machine design experience for optimisation of electrical machines. This capability allows AML to perform design studies as a key component of the ‘Customer On-Boarding Process.’ The process flow for achieving an optimised solution begins with no charge first order design study providing the customer with a full design space exploration, generating design trends and the relevant design tradeoffs like, for example, power density versus efficiency, specific power versus aspect ratio, or the impact of frequency on power density and losses.

It can include analysing the performance of different alloys and the relationship between critical REE content, specific power, and efficiency. Follow-on activities can include electrical machine design and prototyping, depending on magnet manufacturing and the customer’s preference.

Customers have three options for considering the AML approach for their motors or generators. ‘Plug-and-Play’ retrofit of the rotor with no changes to the stator, as well as full optimisation, including changes to the stator or a ground-up new design.

Please note, this article will also appear in the seventeenth edition of our quarterly publication.