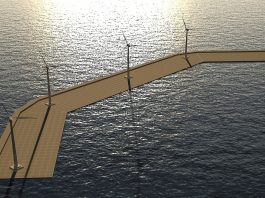

Pneumatically Stabilized Platform (PSP) is a marine technology specifically designed as a very large floating platform located in unprotected ocean waters.

Float Inc. has come a long way since 1992, when its Pneumatically Stabilized Platform (PSP) marine technology was accepted as a candidate for the USA Department of Defense’s ‘Mobile Offshore Base’ project. The Pneumatically Stabilized Platform was developed with USA Defense Advance Research Agency (DARPA) and the Office of Naval Research (ONR) support and proved in model scale; the PSP achieves its at-sea motion stability and structural loads mitigation by decoupling the ‘hull’ from ocean wave pressures through the partial use of mobile air buoyancy.

DARPA / ONR Contracts with Float Incorporated

In January 1993, The Naval Surface Warfare Center, Carderock Division, took an interest in the PSP’s potential to serve as a floating military base. Float’s proposal was for a three-phase effort to construct a 30m by 91m prototype to be deployed off the coast of San Diego, California, to demonstrate the Pneumatically Stabilized Platform technology. When it became clear that it would not be possible to obtain sufficiently firm estimates for the costs of construction and deployment without completing the Phase 1 and 2 two research and design effort, DARPA elected to proceed with the first two phases, deferring the third until their completion. DARPA awarded Float a contract as part of its Maritime Platform Technologies program. This contract, for $1.34m (€1.23m), was funded in August 1995.

Phase 1 was conducted between August 1995 and December 1996. The first task was the development of the hydrodynamic and structural computer models needed for the design of the prototype platform. Next, a 1:22.85 physical scale model of the prototype was designed, built and tested at the Offshore Model Basin wave tank in Escondido, California.

As it was not practical to fully scale air pressure, the first test model, which was comprised of 75 cylinders, was designed to have only five active cylinders. Consequently, the Phase 1 model tests were limited to confirming the computer models’ prediction for the compliance of the air contained in the five cylinders (the ‘air pocket factor’) and the platform’s motion in a seaway.

In early 1997, following a revision in DARPA’s objectives, Float’s effort was transferred to the Office of Naval Research (ONR) for inclusion in its newly formed Mobile Offshore Base (MOB) program. Work was suspended during this change of administration; thus Phase 2 did not commence until August 1997. The shift necessitated several changes in the direction of the research effort. Most important was the replacement of the 30m by 91m prototype demonstration platform with a 152m by 365m platform as the principal study objective. Float was requested to examine the application of Pneumatically Stabilized Platform technology to a variety of smaller ancillary support platforms.

Extensive model tests were conducted at the Offshore Model Basin in Escondido, California during June and July of 1998. A scale of 1:48.73 was selected and models representing platforms 182m x 121m and 60m x 365m in prototype scale were constructed. Tests were conducted with the models constrained (fixed to a truss spanning the basin) and free floating. Several air exchange (manifold) configurations were studied. 30 wave sets, with periods from six to 20 seconds, wave lengths from 54m to 624m and wave heights from 1m to 20m, all in prototype scale, were used. Installed sensors measured cylinder air pressure, water pressure at the base of the model, wave height within the cylinders, motion of the models in six degrees of freedom and the forces exerted by the model on the supporting truss.

Although the air pressure was not scaled, these tests were designed to study the performance of a PSP when all cylinders were active, i.e., able to exchange air. The test data showed the wave attenuation to be very rapid; the height of the waves being significantly reduced after passing but a few cylinders. Further, the data clearly established the relationship between the air distribution, wave attenuation and platform motion.

Rapid attenuation indicates that the largest hydrodynamic loads will be confined to areas near the perimeter of the platform, which is expected to ease its structural requirements. It also suggests that the focus on air handling and energy conversion will be in cylinders near the perimeter of the platform and that the central areas of large platforms can be constructed more economically.

Offshore Floating Ocean Energy System

In December 2009, Float Inc. redesigned the Pneumatically Stabilized Platform to accommodate the Rho-Cee Wave Energy Converter (ρC) into the patented Float Inc. Offshore Floating Ocean Energy System (OFOES), capable of capturing and converting offshore deep water wave energy resources into usable grid electricity.

The Offshore Floating Ocean Energy System represents a major advancement towards the capture and conversion of combined renewable energy sources (wind, wave, and ocean current) that prevail worldwide. Additionally, the OFOES is specifically designed to adapt to the candidate site specificities, which enhances application possibilities.

Most importantly, the OFOES, as a multi-task floating platform, accommodates a number of ancillary applications thereby reducing the Levelised Cost of Electricity (LCOE) generated onboard, as well as the CAPEX and COPEX costs, by combining use of the OFOES with one anchorage system; one transformer system; one submarine cable ashore. Additionally, the capability exists within the interstitial spaces of the PSP to store generated electricity in the form of compressed air – Potential Energy Storage – which acts as an ‘electricity source reserve’ in the event of electricity production shortfall. Additional potential ancillary applications include:

- Operations and maintenance personnel and equipment are accommodated onboard;

- Spare and repair parts are stored onboard;

- Aquaculture and related activities;

- Marine observations;

- Offshore port facilities;

- Leisure facilities; and

- Floating real estate.

From the Rho-Cee Wave Energy Converter viewpoint, the OFOES system provides a ‘terminator’ configuration function. All of the targeted wave energy can be harvested along a single, frontal wave line. The OFOES has a large span, measured in wavelengths; and is given a degree of ‘sweepback’ so that coherent summation of wave forces is avoided, thus reducing the mooring loads (hence cost) and other stresses in the OFOES system.

In terms of energy (power) capture (absorption), the basic design and operating principles are drawn from fundamental wave mechanics as well as cost optimisation calculations. Specifically, that energy transfer between connected waveguides is maximised by providing impedance matching. In principle, when so provided, no energy is reflected or bypasses the junction – it is all absorbed.

The characteristic impedance of gravity waves is simply ρC, the product of mass density X velocity of propagation, known as ‘Rho-Cee’. That impedance, the ratio of pressure-to-particle velocity, is a relatively small number and is resistive, that is, the pressure and particle velocity must in-phase.

To satisfy these two criteria (small and resistive) the input impedance presented by the WEC absorber must be provided by a resonance, with appropriate linear damping.

In the Rho-Cee, these requirements are met by utilisation of an L-shaped oscillating water column (OWC) with the submerged horizontal leg opening in the wave front direction, as required to provide the proper phase-in of its impedance. The resistance is provided and controlled by the power take-off (PTO) system and its load – the delivered power.

The sizing and configuration of the OWCs (typically, three are geometrically nested to provide an economically viable frequency (period) bandwidth using narrower bandwidth oscillators) is based on the principles of vibration and reciprocity, wherein an effective wave absorber would behave as an effective wave generator if/when operating ‘in reverse’.

The Rho-Cee WEC is constructed entirely of steel-reinforced concrete, identical to the supporting Pneumatically Stabilized Platform. It is configured in bays joined by vertical-leeward bulkheads, similarly constructed. The PTO system employs vertically oscillating linear generators. Each is configured as a moving cylindrical collar of pick-up coils enclosing a fixed cylindrical column of permanent magnets.

The mechanical impedance provided by these columns is regulated by their associated control systems. The width of the bays is currently selected in consideration of the integral number of PTO columns required to efficiently provide the load in each, as well as to avoid any rocking motion tendency of the column-resident floats that drive these linear generator PTO columns.

The combination of the PSP and the Rho-Cee Wave Energy Converter produces one of the most predominant characteristics of the Float Inc. Offshore Floating Ocean Energy System4 (OFOES) – combined multi-task capabilities, i.e. transport, multiple renewable energy sources (capture; conversion; storage and transmission), aquaculture, and leisure, floating real estate, etc., reduces capital investment costs and O&M time and costs by a “sharing of costs” amongst the various primary and ancillary applications supported on the same OFOES, i.e. one transformer station: one anchorage system, one submarine cable ashore.

Maintenance personnel can live and work on the OFOES which reduces the overall equipment annual downtime. The storage of spare and repair parts onboard the OFOES permits onboard maintenance personnel to perform efficiently and “in the high and dry”. The internal volumes of the OFOES provide a substantial Potential Energy Storage5 and regeneration system.

Individual renewable energy sources capturing/conversion systems require anchorage, electrical sub-stations, electrical cabling systems and connections which are all incorporated within the Float Inc. OFOES, consequentially economies are attained via the re-grouping of all individual requirements onboard the same OFOES.

Float Inc. is at the threshold of a great adventure but is required to demonstrate the marine technologies encompassed in the OFOES. Industry has devised a system of Technical Readiness Level (TRL) indicators which are to be successfully demonstrated via tank testing, full size demonstration models, to finally achieve the category of a commercially productive model.

Float Inc. is now researching funding to fulfil the industry-required steps of TRL verification and confirmation towards attaining a commercially productive level.

Franklin Martin

Managing Director

Float Marine Technologies Europe Ltd

+33 (0) 493 378 543

franklin.martin@bbox.fr