While lithium-ion batteries hold great potential for the future of sustainable energy, a few issues still need to be addressed. Xerion Advanced Battery Corp. is at the forefront of developing solutions to these problems.

As the world races toward decarbonisation goals aimed at mitigating the impacts of climate change, batteries have taken a central role in the shift away from fossil fuel reliance. Lithium-ion batteries specifically have emerged as a key innovation in the clean energy transition since their inception over 30 years ago. From electric vehicles (EVs) to renewable energy storage systems, these advanced batteries are the enabling technology driving the shift away from fossil fuels. However, while current lithium-ion battery technologies offer many benefits, there remains a long way to go in addressing the shortcomings of these technologies.

Lithium-ion batteries have become the technology of choice for a wide range of applications due to their exceptional energy density, long cycle life, and low self-discharge rate. These advantages have made them the go-to power source for consumer electronics, power tools, and, most importantly, EVs and stationary energy storage systems.

The transportation sector, responsible for a significant portion of global greenhouse gas emissions, is undergoing a seismic shift towards electrification. Major automakers have announced ambitious plans to phase out internal combustion engines in favour of EVs, driven by increasingly stringent emissions regulations and consumer demand for more sustainable transportation options.

Similarly, integrating renewable energy sources, such as solar and wind, into the electricity grid has created an urgent need for large-scale energy storage solutions. Lithium-ion batteries store excess renewable energy when production exceeds demand and release it back into the grid when needed, ensuring a reliable and sustainable electricity supply.

Unfortunately, despite the great promise that lithium-ion batteries offer for advancing the transition to clean, renewable energy, technologies on the market today possess significant drawbacks. Namely, the technologies and configurations dominating today’s market are expensive and reliant on unstable supply chains. Beyond the costs, there are opportunities for improvement in both the performance and safety of Li-ion batteries.

Xerion – Building a better lithium-ion battery

Further innovations are required to harness the true potential of lithium-ion batteries as a driver of the energy transition. At Xerion, we are doing just that. Xerion has spent more than a decade flying under the radar, quietly developing a high-performance, low-cost lithium-ion battery technology platform that now promises to not only revolutionise the battery and short-term energy storage sector landscape but also to propel the electrification of the global economy forward. Xerion’s revolutionary manufacturing platform is founded upon two patented core technologies – DirectPlate™, an innovative refining and deposition technique, and StructurePore™, a novel battery electrode architecture.

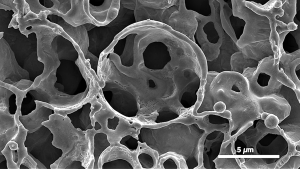

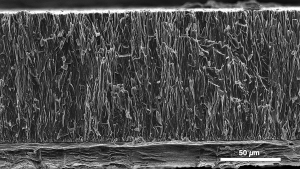

Xerion’s DirectPlate™ manufacturing process leverages a molten salt electroplating process to eliminate many of the steps and materials required in traditional lithium-ion battery manufacturing processes. The company’s novel StructurePore™ nanostructured metal foam electrode architecture dramatically reduces resistance, allowing lithium ions to move rapidly through the battery. This architecture also minimises the potential for thermal runway by reducing heat generated by the battery during failure events, granting significant safety advantages over traditional lithium-ion batteries.

Combined, these core technologies deliver a dramatically lower-cost lithium-ion battery with higher energy density, more power, faster charge, longer life, improved safety, and 40% lower carbon emissions than conventional battery manufacturing.

Optimising battery manufacturing sustainability

An under-discussed element of the ever-growing demand for lithium-ion batteries is ensuring that procuring critical battery materials, such as lithium and cobalt, remains sustainable. Demand for these materials is far outstripping supply, as the International Energy Agency (IEA) reported that the global demand for lithium tripled between 2017 and 2022, and it is projected to double again by 2030. With that increased demand comes increasing importance to optimise sustainability.

Xerion’s cutting-edge technology is elevating sustainability to new frontiers. The company’s DirectPlate™ manufacturing process has yielded a critical innovation as it pertains to the environmental impact of battery supply chains. This revolutionary process extracts lithium directly from geothermal brines, which exist in abundance in regions such as California’s Salton Sea and South America’s Lithium Triangle. This novel ceramic redox membrane technology allows for low-cost, highly efficient extraction of lithium from geothermal brines with minimal impact on the surrounding environment. While the concept of extracting lithium from geothermal brines, in a process called direct lithium extraction (DLE), is currently utilised, existing methods have been plagued by poor lithium selectivity, material instability, and high cost.

In contrast, Xerion’s technology is exceptionally resistant to the temperature and chemistry of geothermal brines, providing the required lithium selectivity and durability for practical application. The company has demonstrated this technology is capable of efficiently extracting lithium from raw geothermal brines with low lithium concentrations to produce high-quality lithium hydroxide. This lithium hydroxide can be used directly as a battery feedstock to synthesise cathodes in a single step using Xerion’s DirectPlate™ molten salt electroplating process, converted to a lithium metal anode for use in solid-state batteries, or as feedstock for the current conventional slurry cast cathode production process.

Notably, Xerion’s DirectPlate™ process can also use less pure, 100% domestically sourced battery precursors and can be adapted to recycle end-of-life batteries, allowing for increased circularity and waste reduction within the battery supply chain.

Strengthening domestic supply chains

As the demand for lithium-ion batteries continues to surge, another critical challenge emerges: Establishing a robust and secure domestic battery supply chain. The production of lithium-ion batteries involves a complex global supply chain, and the United States is currently heavily dependent on international markets for the sourcing of lithium, resulting in high costs, supply chain challenges, and national security concerns. Today, Australia, Chile, China, and Argentina produce over 90% of the world’s lithium, while the vast majority of lithium-ion batteries – roughly 77% of global supply – are produced in China.

To address these challenges, the United States must prioritise the development of a domestic battery supply chain, from raw material sourcing to advanced manufacturing capabilities. Xerion is deeply committed to leading the charge on this front and passionately believes that its technology offers a significant opportunity to make strides toward that goal.

In sum, lithium-ion batteries are a valuable tool for electrifying global economies as we transition to renewable energy, but we cannot remain satisfied with the status quo of today’s technologies. Continued innovation is an absolute requirement moving forward, and those innovations must be focused on improving performance and cost, securing supply chains, and reducing environmental impact. Xerion is committed to these ideals.

Please note, this article will also appear in the 18th edition of our quarterly publication.