With its premium carbon black grades, Orion Engineered Carbons offers sustainable and highly conductive carbon black solutions for lithium-ion batteries.

Orion Engineered Carbons is a global specialist chemicals company with more than 160 years of experience producing carbon black grades for tyres, rubber goods, plastics, coatings, printing inks, batteries, and high-performance applications. Orion has 14 production sites worldwide and four innovation centres on three continents, offering the widest variety of production processes in the industry. The company’s strong knowhow, and the Orion team’s commitment, make possible a close communication with customers to find innovative solutions for their needs.

As a global company, one of the main strengths of Orion is the diversity of its employees, who constantly contribute with new ideas and seek excellence. Orion values talented people and strives for their continuous development, regardless of nationality, gender, age, or sexual orientation.

Orion’s core values – accountability, innovation, and enduring relationships – are integrated into the company’s culture and are fundamental in the decisions made by the company.

Driving the decarbonisation of the transport sector

As a technology innovation driver, Orion is focusing on the promise of e-mobility in decarbonising the transport sector and creating a carbon-neutral economy. The main energy storage system in electric vehicles (EVs) are lithium-ion batteries (LIBs) – a system comprised of two electrodes (anode and cathode) and a separator between them. The system is immersed in an organic electrolyte. Lithium-ion batteries store energy through chemical reactions in the cathode and anode electrodes. The main advantages of LIBs, in comparison with other energy storage systems, are the high energy density and long cycle life.

Carbon black is a fundamental component in the electrodes in a LIB, because it increases the electrical conductivity of the system, enabling a better battery performance. Currently, the total market demand of carbon black for LIBs is 20kt. This figure will increase as the demand for LIBs in the e-mobility and other applications increases. By 2030, it is expected that the total carbon black demand for LIBs will be around 84kt.1

What is carbon black?

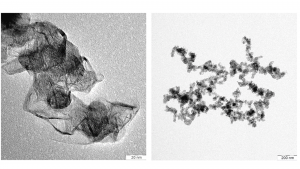

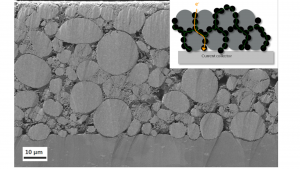

Carbon black is a form of carbon produced by the incomplete combustion of hydrocarbons, and it consists of spherical carbon particles in the range of 10-500 nm size. The core of the carbon black particle is amorphous, while the outer layer is formed of graphite-like domains,2 conferring intrinsic electronic conductivity to the material. The structure of the carbon is defined by the fuse of carbon black particles into branched aggregates. Both properties, conductivity and structure, are fundamental for the battery performance because it is through the branched aggregates (percolation network) of conductive carbon black particles that the electrons generated in the electrodes are transported to the current collector. In the lithium-ion battery field, the carbon black is known as a ‘conductive additive’.

Another important parameter to consider are metallic contaminants. Metals particles of, for example, iron (Fe), cobalt (Co), nickel (Ni), copper (Cu), and zinc (Zn) might have a negative impact on the battery lifetime.

Acetylene black is a type of carbon black characterised by its high electronic conductivity, high structure, and excellent purity. These properties make acetylene black a preferred conductive additive for LIBs. In 2018, Orion acquired SN2A, a French manufacturer of acetylene black and developed its first carbon grade for lithium-ion batteries, PRINTEX® kappa 100.

PRINTEX kappa 100

PRINTEX kappa 100 is a premium carbon black grade specially designed for LIBs. The clean feedstock and unique production process used to manufacture PRINTEX kappa 100 results in a highly pure, highly graphitised, and highly structured material.

High purity: PRINTEX kappa 100 is manufactured by the thermal decomposition of acetylene gas under a high-quality process. With more than +99% carbon content and very low metal impurities, Fe << 5 parts per million (ppm), Cu and Zn in the order of low ppm to ppb range, batteries with PRINTEX kappa 100 exhibit low self-discharge and long cycle life.

High graphitisation: PRINTEX kappa 100 is manufactured at very high temperatures (>2300°C), resulting in a material with a high degree of graphitisation which gives low moisture content, high conductivity, and good chemical stability at high voltage conditions.

High structure: The high structure of PRINTEX kappa 100 allows the easy dispersibility of the carbon during the electrode preparation and the formation of a long chain percolation network that will reduce the internal resistance, improving the cycle life and the performance of the battery at high power densities.

Besides, with the lowest CO2 footprint among other highly conductive carbon black grades, PRINTEX kappa 100 is considered an environmentally-friendly material.

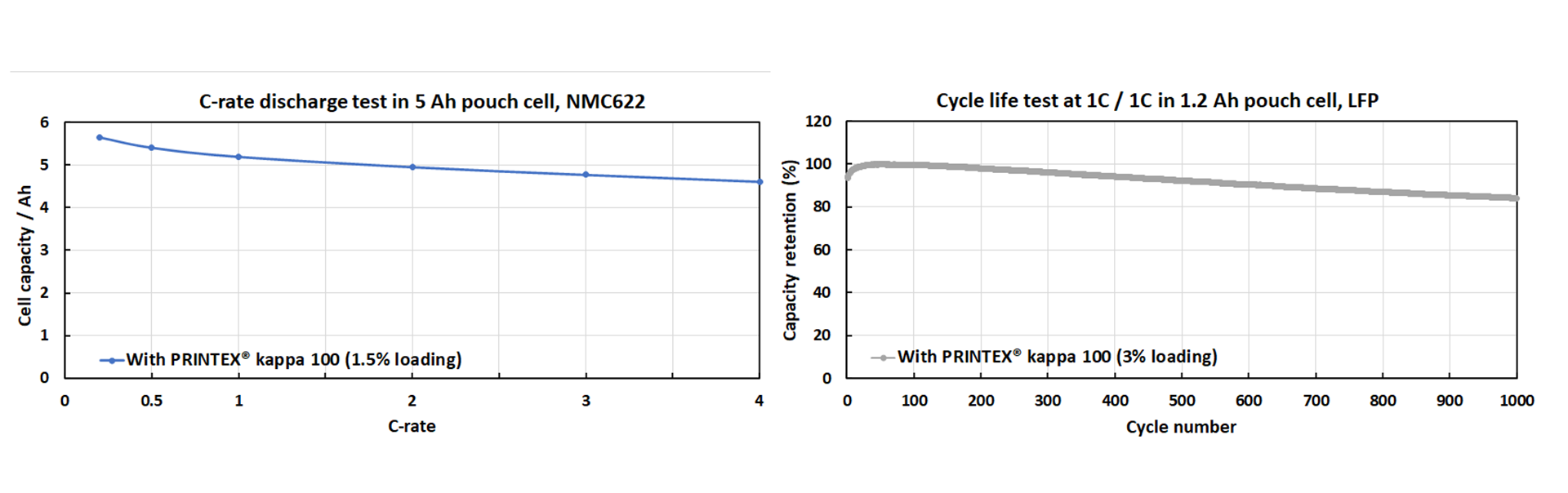

PRINTEX kappa 100 can be used in the cathode and anode electrodes of lithium-ion batteries with different chemistries. Discharge C-rate tests were done in 5 Ah pouch cells using lithium nickel manganese cobalt oxide (NMC622) as active material and PRINTEX kappa 100 as a conductive additive. Results indicate a capacity retention of 85% at 4C. In another series of experiments, PRINTEX kappa 100 was used in lithium iron phosphate (LFP) electrodes to perform cycle life tests in 1.2 Ah pouch cells. The results show a capacity retention of 84% after 1,000 cycles.

This year, Orion announced the building of a green field plant in La Porte, Texas, to produce acetylene black. With this initiative, Orion will be the only company manufacturing acetylene black in the US supplying regional and global LIB customers. The plant’s start-up is expected to take place in the second half of 2024, quadrupling the company’s effective manufacturing capacity of acetylene-based additives, increasing it by 12 kTon per year. Among other products, PRINTEX kappa 100 will be one of the premium grades produced in this new facility.

Continuous development

Orion’s constant development and search for customer satisfaction occurs at all levels, and the innovation team is continuously working on new carbon blacks to fulfil current and future market requests. The development of new grades takes place internally, where scientists, production engineers and marketing work together to find the best solutions for customers and, externally, in collaboration with other companies and academic institutions, to develop integral solutions to strengthen a particular region or industry.

One of Orion’s internal projects is the development of highly conductive carbon black grades using the furnace black process. The advantage of the technology is its flexibility that allows the manufacture of a broad variety of carbons with different material properties that can be used in different applications. Just like with acetylene black, the furnace black grades for batteries must be highly conductive, high structured, and very pure. In an interdisciplinary collaboration between departments and regions, the Orion team is committed to developing new premium grades that exceed the expectations of customers.

As part of the external collaborations, Orion participates in the HiQ-CARB project, a European Union funded project that aims to develop sustainable, locally produced conductive additives, acetylene black and carbon nanotubes, to be used in lithium batteries. By granting projects like the HiQ-CARB, the EU is looking to create a competitive manufacturing value chain in Europe for LIBs and decrease the technological dependence on other regions. In this project, the low CO2 footprint acetylene black from Orion and the resource-efficient carbon nanotubes (CNT) from the project partner Arkema are manufactured and tested in the LIB. The synergistic effect of both conductive additives, short-range electrical pathways of acetylene black and the long-range electrical pathways of CNTs, are also studied. The environmental impact of acetylene black and CNT will be evaluated through a life cycle assessment.

Aware of the current and future demands of the lithium-ion battery industry, Orion embraces the challenge and continues working on the development of integral solutions to manufacture premium conductive carbon additives, focusing on the customer needs and in the technical requirements of the next generation of batteries.

Orion’s commitment to a more sustainable future reflects its effort to deliver the best products while being socially and environmentally responsible, making sure the future of carbon black is green.

References

1: Avicenne Energy 2022 and Orion assumption

2: N Hauptman, A Vesel, V Ivanovski, M Gunde. Electrical conductivity of carbon black pigments. Dyes and Pigments 95 (1) (2012) 1 – 7

Please note, this article will also appear in the twelfth edition of our quarterly publication.