Jan Erik Hanssen, Co-founder of Enerocean, details how we can address the financial obstacles preventing the widespread acceleration of offshore wind power.

Floating technology can bring the benefits of offshore wind power to countries and seas out of its reach today. For economies of scale to kick in, floating offshore wind power needs to achieve GW-scale deployment with zero or minimal subsidies, whilst the cost of most floating offerings in the market is still way over that of seabed-fixed technology. This is a major ‘Catch-22’ situation for the nascent floating industry. Enerocean’s W2Power has unique design features, proven at sea, that can accelerate deployment and thus significantly contribute to breaking the cost barrier to offshore wind power.

In a previous article on Innovation News Network,1 key features of Enerocean’s W2Power floating wind solution were summarised. In this article, we look at how some of these innovative features were proven in open-sea testing and how W2Power’s resulting cost advantage can kickstart major and wider adoption already in the early deployment phase. A third paper focuses on its economic upside potential by multi-use of the sea space.

Any delay in the deployment of floating wind could mean a big problem for Europe. A recent study of near-term deployment of innovative renewables2 found that the EU’s floating wind capacity actually deployed by 2030 is likely to be in the single-digit Gigawatts, far behind policy objectives and much less than expected a few years ago. With GW-sized seabed-fixed farms now routine, the majority of floating developers are planning arrays only slightly bigger than today’s 88-MW Hywind Tampen, citing higher costs for their floating technologies than seabed-fixed wind. The trend was noted also by 4c Offshore, whose forecast for 2030 is down by 2GW from just six months earlier.3 Major utility Ørsted now predicts 5.9GW of floating wind deployed in 2030, of which 4GW in European seas.4 If this trend is maintained, floating’s contribution to EU net-zero goals will be significantly delayed, and investment risks being diverted to other technologies.

W2Power advantages proven at sea

With the basic layout of W2Power protected by a strong foundational patent, Enerocean’s IP on the solution extends far wider, covering engineering, construction, and operation. This article summarises how these innovative features were proven by the four months of open-sea tests. A new sea-testing campaign with the same prototype (2022/23) will be described in the third article in this series.

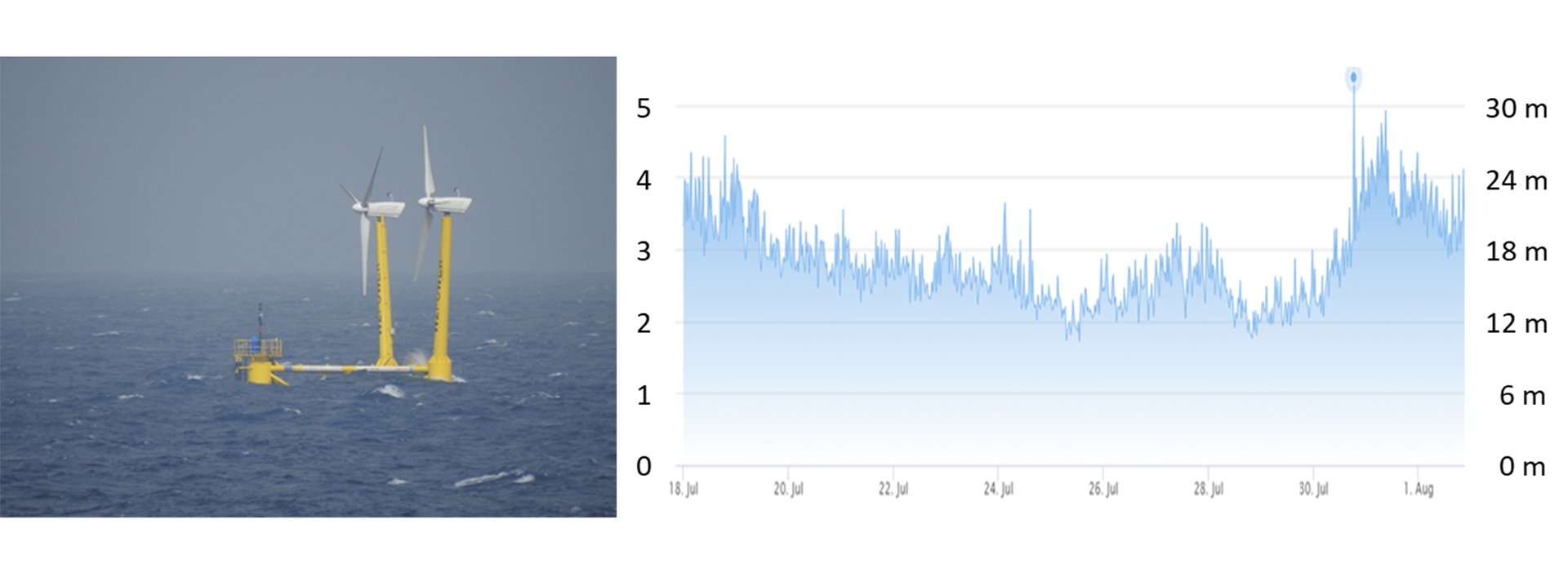

Fig. 1 is an actual photo of the W2Power prototype in one of the seven storms encountered in the open sea, and the recorded wave heights. Keep in mind that the unit tested was 1:6 scale. Measured loads and movements can be extrapolated to the full size. The highest wave of 5.39m causes wave-platform interactions comparable to waves of 32m in height on the full-size platform.

Construction

Construction of the 1:6 scale prototype proceeded closely in parallel with the detailed engineering of the full-size W2Power within the framework of an EU-funded ERA-NET, DemoWind.5 Except for the scale, allowing accelerated testing for survivability at the harshest met-ocean conditions, the prototype is identical to the full-size version and tested nearly all its essential features (in autonomous operation). Details about the construction process have been presented as an invited keynote at the U.S. Department of Energy.6 The present paper focuses on the sea-testing results and cost prospects.

Operations

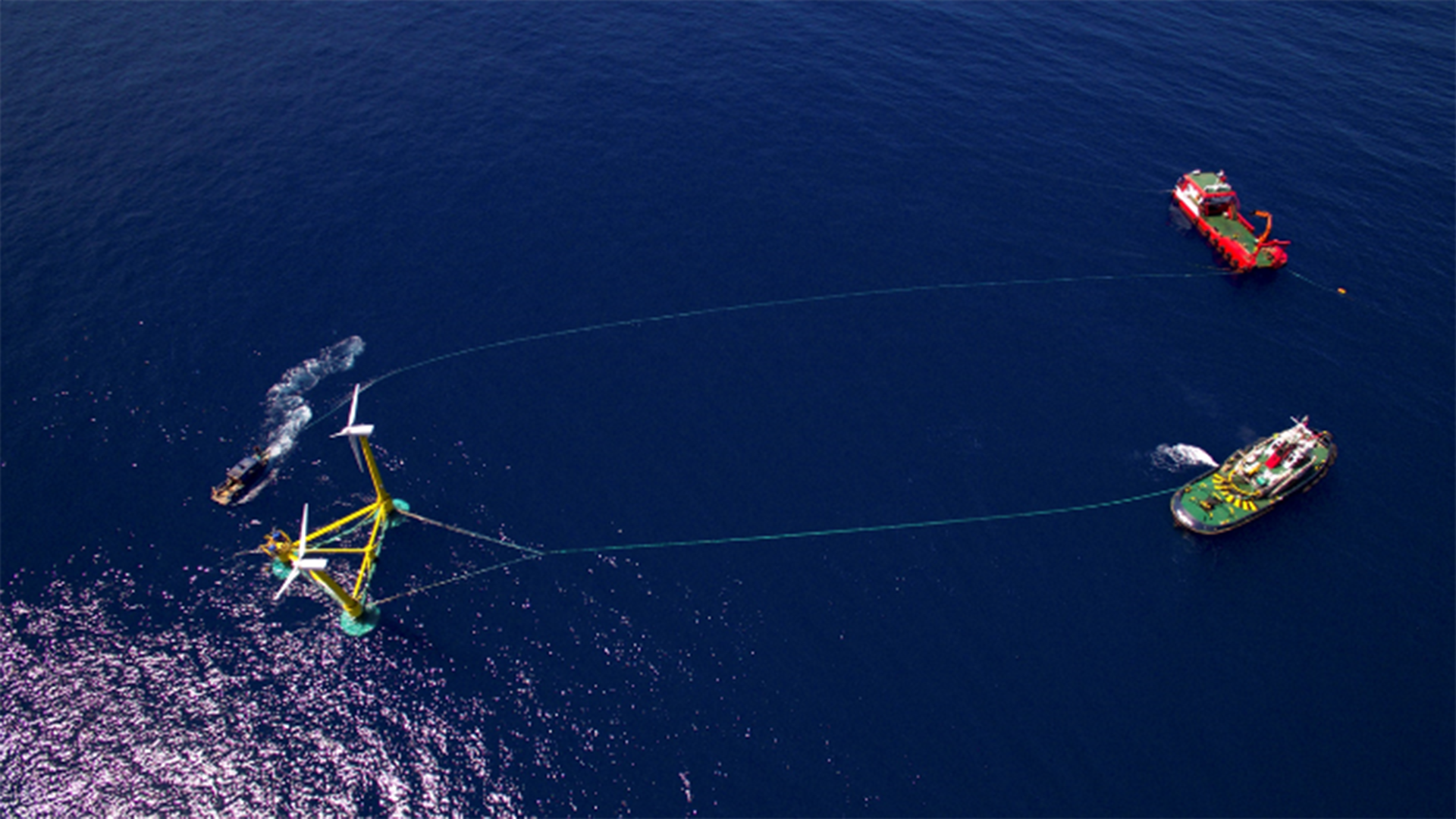

From local yard Astican, the 30-tonne prototype was towed out from Las Palmas industrial port by a single tugboat after quayside commissioning had verified all sub-systems. At the test site (70m deep), the pre-laid moorings and anchors were connected up, all in three hours (Fig. 2).

Stability and reliability at sea were demonstrated by there being no need to access the unit, or even switch to emergency mode, during the four months at sea. Platform yaw (without yawing the individual turbines) was proven fully functional even in moderate winds. Even high wave loads, such as those shown in Fig. 1, had no material influence on W2Power’s wind-vaning performance.

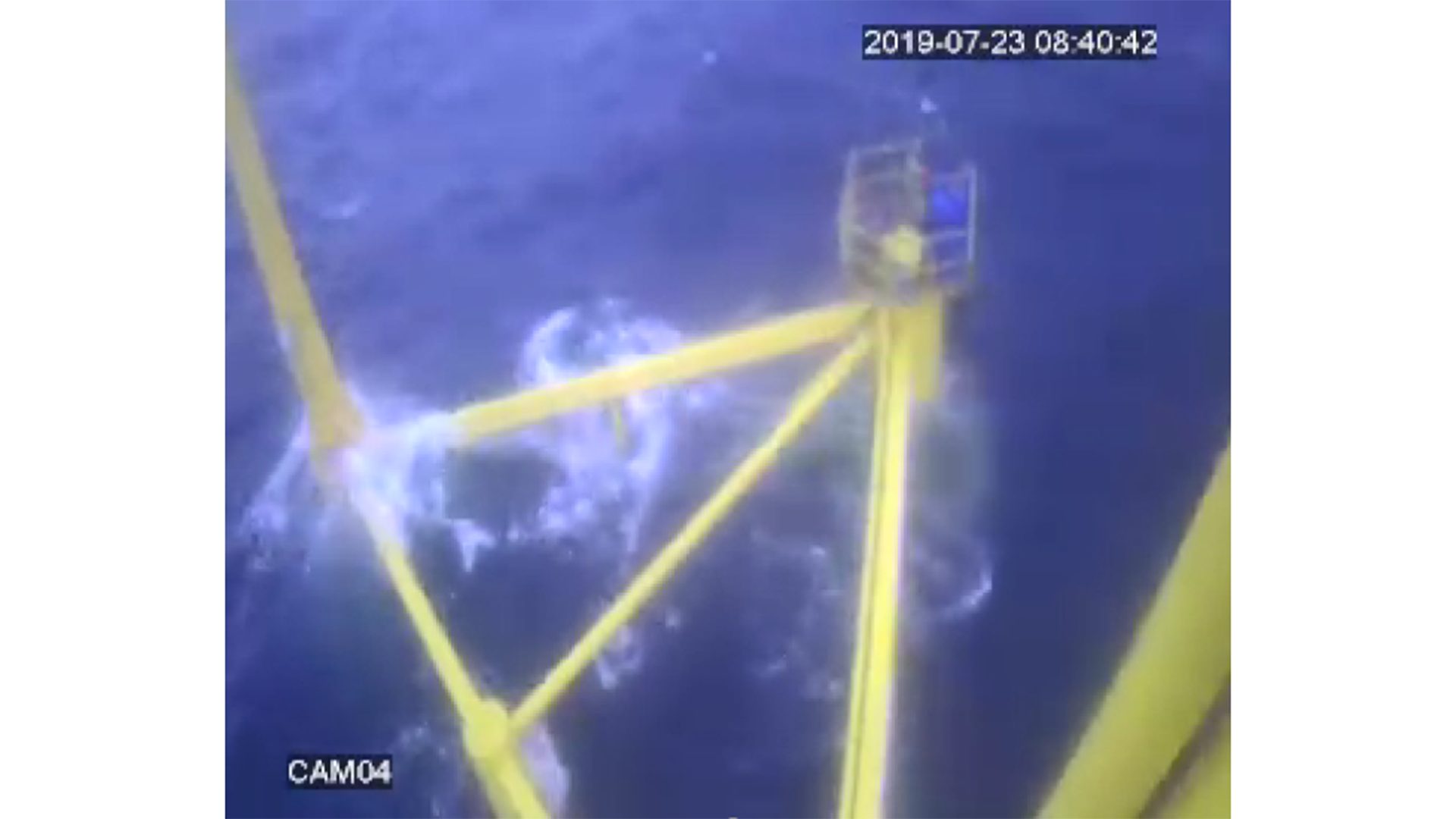

Video cameras in each turbine and at other critical positions recorded important events, of which two typical scenes are shown in Fig. 3. A short video digest is available on www.enerocean.com.

Analysis of the video sequences provided invaluable insights and quantitative data for assessing the prototype’s performance at sea. Predictions from tank-test data on small-scale models7 matched by numerical simulations were confirmed. Measured response amplitude operator (RAO) values in heave were below 0.4. Even at storm conditions, the inclination and acceleration data lie well within the limits specified by wind-turbine original equipment manufacturers (OEMs) in continuous power-production mode, confirming the excellent overall system performance. Estimations calibrated by sea-test data show that, for all development cases studied so far, maximum accelerations and inclinations for the turbines in use at sea will be significantly below the OEMs’ limits. Consequently, little or no additional effort by OEMs will be needed for use of their standard turbines in pairs on W2Power platforms. Overall, the W2Power displays a stability approaching that of Spar-buoy systems like Hywind.8 Yet its low-draft, ultra-light semi-submersible construction offers excellent cost-optimisation potential.

Operating in autonomous mode, the wind turbines were continuously monitored for pitch control and production performance, feeding the power generated to on-board resistance heaters. A pilot version of an advanced ultrasonic based condition-monitoring (CM) system owned by Enerocean, the result of a string of EU-funded projects9 showed the power of this approach for O&M optimisation and reliability. Throughout the open-sea testing, the function-critical swivel connection sub-system connected to a site-optimised hybrid fibre/chain mooring system, with three mooring lines and anchors, was monitored and controlled from shore by a custom SCADA system as seen on Fig. 4.

In summary, learning from actual sea-test behaviour proved invaluable for final optimisation of the control system and fine tuning of the full-size design.

After tow-back to yard, a detailed inspection of the prototype showed no sign of structural damage. Some bio-fouling was observed, but a simple bio-remediation process cleaned it up rapidly without any environmental emissions.

Cost-efficiency

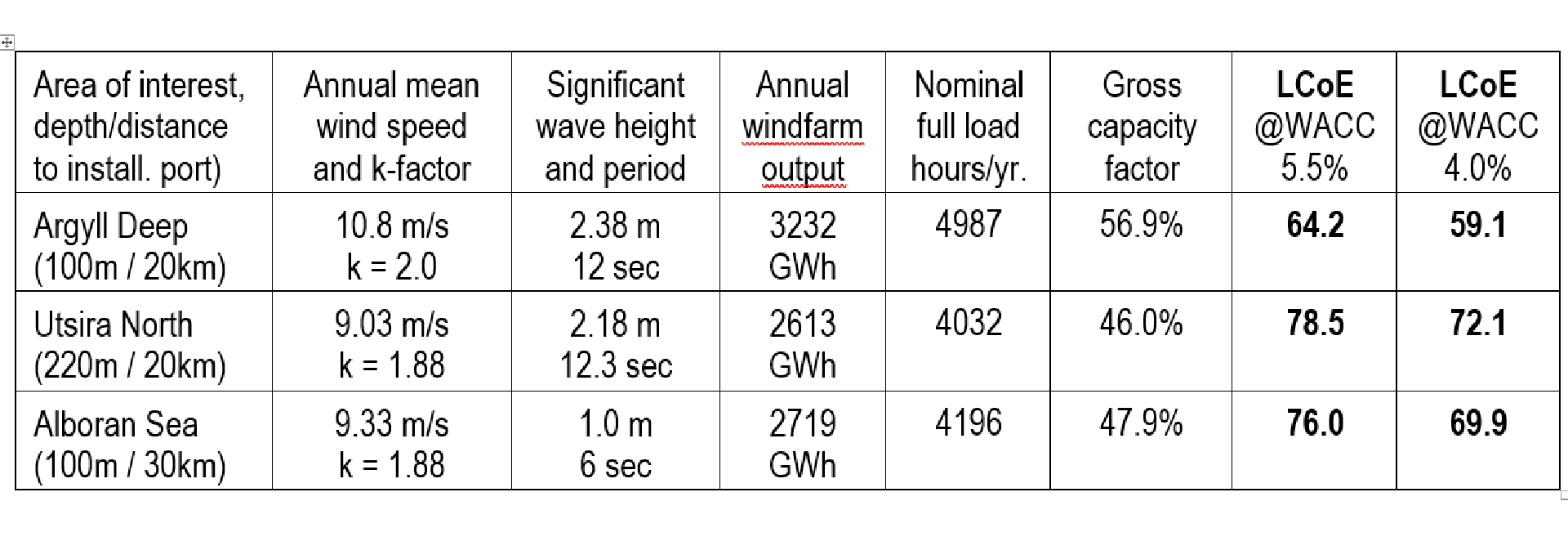

Concurrently with the W2Power full-size engineering and the open-sea test campaign, a costing exercise was carried out for three promising floating sites in Atlantic, North Sea, and Mediterranean waters. The costing tool used has a long history of use from levelized cost of energy (LCoE) modelling in a string of EU-funded projects.

Fully transparent to users, the model estimates CapEx, OpEx and farm performance accounting for local energy resources and costs of construction, installation, O&M, and decommissioning. It handles, in a simplified but comprehensive way, all aspects of a field development, including off-and onshore cabling, down to details such as installation vessel day rates, sailing speed and distance. Especially useful for rapid parameter variation and sensitivity studies, it can be used from farm developments down to single demonstrators, as it was first calibrated on the Hywind Demo, whose developer was part of its early development. Results for the three sites are shown in Table 1.

At the best WACC, W2Power achieves LCoE at or below 72 €/MWh at all three sites, approaching bottom-fixed wind. Note that these estimates result only from scantling data of the full-scale design and sub-systems cost from prospective suppliers. They assume no ‘learning curves’ or ‘economies of scale’ (which, of course, will further improve LCoE). Thus, commercial floating wind is within reach today, and the perceived cost barrier to floating offshore wind power is due to other technology offerings not being cost-competitive.

Flexible scaling to current 20MW design

W2Power has progressed through several generations of scale-up and design optimisation as it was pushed through the TRLs. In parallel, Enerocean has since 2012 worked closely with a leading global certification body, issuing Approval in Principle. A Full Design Certification is scheduled mid-2023 for a first-of-a-kind, full-size deployment.

The cost advantage of W2Power, already industry-leading as seen from Table 1, has improved further for the 20MW full-size that now forms the basis for Enerocean’s commercial pipeline of projects with FID from 2025/26. The patent-protected bridge-based design is key here, as it allows expanding rotor diameters, thus power, without proportional increases in floater steel mass and maintaining platform stability and durability.

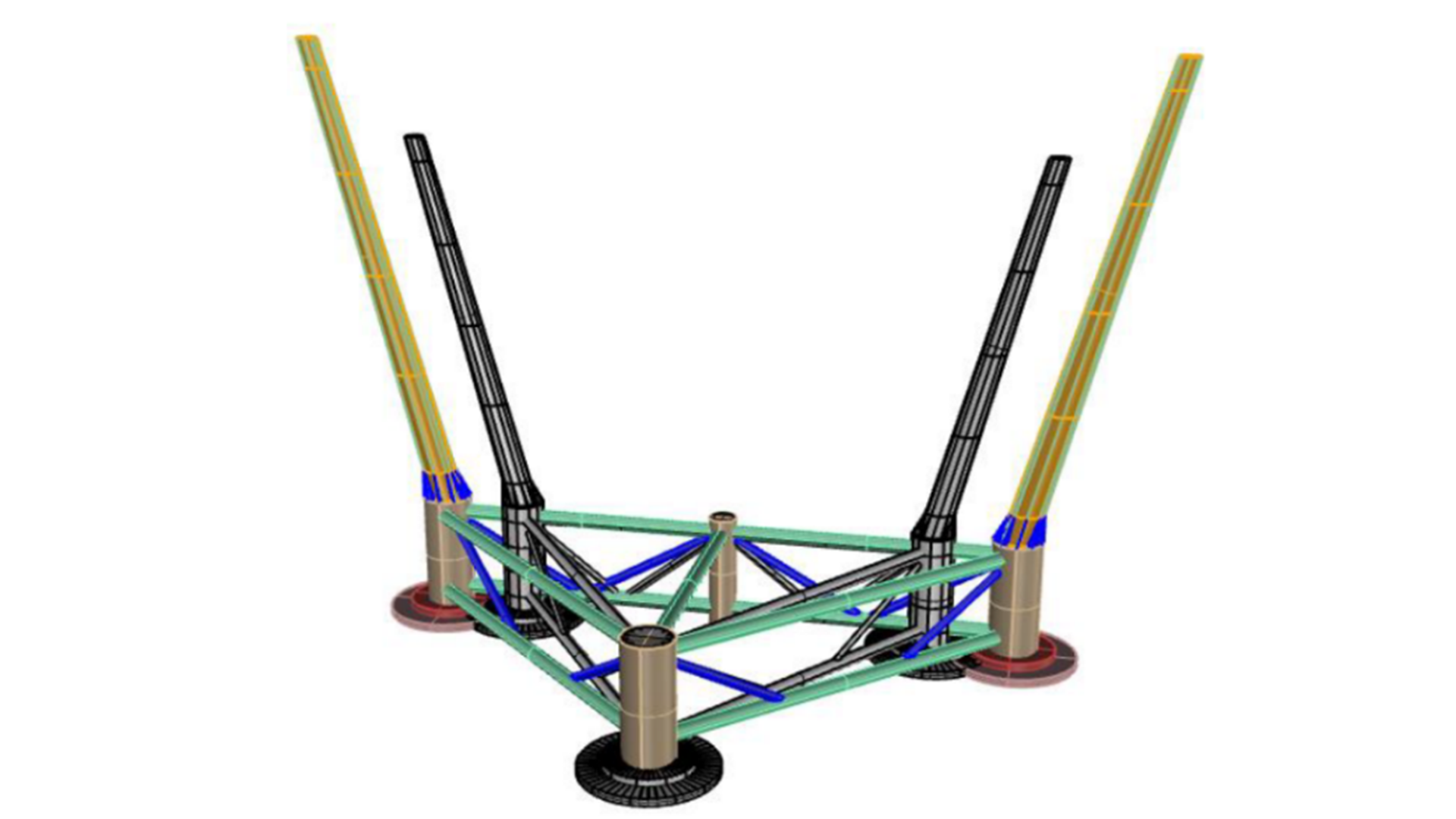

As shown by Fig. 5, in scaling from 12 to 20MW, the W2Power has been intelligently ‘stretched’ for minimum additional steel weight to accommodate larger rotors. Compared to the 12-MW design, rated power has grown by 67%, yet needing only 20% more structural steel.

Taking the mass of platform steel per MW as a useful indicator of CapEx, the 20MW W2Power has an industry-leading 160 metric tonnes per MW. Note that this is not for ‘mild’ conditions: W2Power has always been engineered for deployment at the roughest floating wind sites considered. Further keys to cost efficiency are the smart modular construction, adaptable for fabrication in any region of the world, with optimised sub-components for lean manufacturing. Thus, Enerocean’s W2Power solution has the potential, in the near term, to break the cost barrier and help to unleash GW-scale floating wind deployment for 2030 – with accelerating deployment soon thereafter.

References

- First article in this series, Innovation News Network September 2022 W2Power: Pioneering offshore wind power deployment worldwide (innovationnewsnetwork.com)

- “5% of new capacity from innovative renewable energy”, Press Release Association of European Renewable Energy Research Centres, EUREC, 14.10.2022, Available from https://eurec.be/press-release-5-of-new-capacity-from-innovative-renewable-energy-a-necessary-and-do-able-enhancement-to-the-renewable-energy-directive/

- “Global floating wind on path to miss 2030 targets, report says”, offshorewind.biz 14 November 2022

- Floating Wind whitepaper published Oct. 2022, available online from https://orsted.com/en/insights/white-papers/floating-wind

- Horizon 2020 project DemoWind (Grant Agreement 646517), project acronym “WIP10+”

- Mayorga, “W2Power Twin rotor floating wind platform, specific experience with floating offshore wind development and deployment”, invited keynote presentation at ATLANTIS event, ARPA-E, US Department of Energy, Washington DC, 29-30 January 2020

- Mayorga et al, Experimental validation of the W2Power 13th Deep Sea Offshore Wind R&D Conference, EERA DeepWind’2016, 20-22 January 2016, Trondheim, Norway

- Driscoll et al. Validation of a FAST Model of the Statoil-Hywind Demo Floating Wind Turbine, 13th Deep Sea Offshore Wind R&D Conference, EERA DeepWind’2016, 20-22 January 2016, 2016, Trondheim Norway

- Mayorga, The “TidalSenseDemo” project, European Ocean Energy Conference 2013, Edinburgh, UK, 2013

Please note, this article will also appear in the thirteenth edition of our quarterly publication.