Scientists from the University of Rochester have pioneered an innovative electrochemical process to remove PFAS chemicals from water.

The researchers’ electrocatalysis approach has been demonstrated to be effective at remedying pollution caused by per- and polyfluoroalkyl substances (PFAS), commonly known as ‘forever chemicals‘.

PFAS chemicals have been widely used in various products such as clothing, food packaging, and firefighting foams, posing significant environmental and health risks due to their persistence in the environment.

This novel approach to removing PFAS chemicals could herald a new era in environmental remediation efforts, ensuring a safer and healthier future for communities worldwide.

Targeting PFAS contamination

Led by Assistant Professor of Chemical Engineering Astrid Müller, the research team focused on addressing the contamination caused by Perfluorooctane sulfonate (PFOS), a type of PFAS extensively used in stain-resistant products.

Despite being banned in many parts of the world due to its detrimental effects on human and animal health, PFOS remains prevalent in the environment, particularly in water supplies.

Innovative nanocatalysts

To overcome this significant environmental issue, Müller and her team developed nanocatalysts using a novel combination of ultrafast lasers, materials science, chemistry, and chemical engineering expertise.

Müller explained: “Using pulsed laser in liquid synthesis, we can control the surface chemistry of these catalysts in ways you cannot do in traditional wet chemistry methods.

You can control the size of the resulting nanoparticles through the light-matter interaction, basically blasting them apart.”

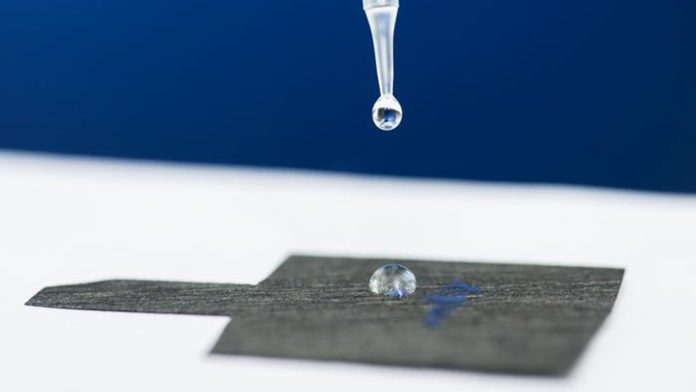

One of the key breakthroughs of this research is the cost-effectiveness of the method. By adhering the nanoparticles to hydrophilic carbon paper and utilising lithium hydroxide, the team achieved complete defluorination of PFOS chemicals.

Importantly, the process utilises nonprecious metals, making it significantly more economical compared to existing methods, potentially reducing the cost by nearly 100 times.

In contrast, treating a cubic metre of polluted water with existing methods that use boron-doped diamonds would cost $8.5m.

Future prospects and sustainability

Looking ahead, Müller aims to further optimise the process by exploring alternative materials to enhance cost efficiency.

She also plans to extend the application of the method to other prevalent PFAS chemicals associated with various health issues.

Despite acknowledging the utility of PFAS in consumer products and green technologies, Müller advocates for their sustainable usage through electrocatalytic solutions.

She explained: “I would argue that in the end, a lot of decarbonisation efforts — from geothermal heat pumps to efficient refrigeration to solar cells — depend on the availability of PFAS.

“I believe it’s possible to use PFAS in a circular, sustainable way if we can leverage electrocatalytic solutions to break fluorocarbon bonds and get the fluoride back out safely without putting it into the environment.”

Müller also emphasised the social justice aspect of the research, highlighting its potential to address pollution disparities, particularly in economically disadvantaged areas.

“Often in areas with lower income across the globe, there’s more pollution,” said Müller. “An advantage of an electrocatalytic approach is that you can use it in a distributed fashion with a small footprint using electricity from solar panels.”

The University of Rochester’s research offers a promising avenue for tackling the pervasive issue of PFAS chemical pollution.

With its cost-effective and sustainable approach and its potential for widespread application, this breakthrough could prove instrumental in the fight against harmful PFAS chemicals.