Circa and the RESOLUTE project are building a first-of-its-kind 1,000-tonne biorefinery to enable the transition to a more sustainable chemicals industry. We’ve made the breakthrough – now we need you.

In a world demanding real change at scale to limit the climate crisis, we are still miles away from replacing the toxic fossil-based chemicals used everywhere in everyday life.

Progress is being made with sustainability now a key objective for all responsible companies, and with corporate responsibilities extending deep into supply chains, the chemical building blocks of everyday products are under increasing scrutiny.

The inception of ReSolute

Circa is one of the few businesses with the technology to produce sustainable chemicals at an industrial scale and the tenacity to make it happen. Having collaborated with hundreds of academic and industrial collaborators to demonstrate the value of the chemicals generated from their patented FuracellTM technology, Circa is scaling up manufacturing with the support of European stakeholders by building its ReSolute plant.

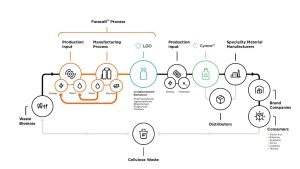

The Furacell technology Circa has developed extracts the bio-based building block levoglucosenone (LGO) from non-food cellulosic biomass in one step by generating a biochar co-product. The building of the ReSolute cellulosic-to-chemicals plant will realise over a decade of lab, pilot and demonstration scale R&D investment and ambition.

It will have the capacity to produce 1,000 tonnes of LGO and also includes the simple additional one-step catalytic hydrogenation process needed to produce Circa’s first LGO-derived solvent product – dihydrolevoglucosenone – or, as it is named, CyreneTM.

Cyrene capacity will also be 1,000 tonnes, given it can be produced with close to stoichiometric yields from LGO.

Cyrene

LGO is a versatile platform molecule that has long been a target of the bio-based chemicals sector but, until now, was unobtainable at a commercial scale. It has the capability to be the intermediate for a portfolio of a hundred or more chemical derivatives and advanced materials with applications across solvents, speciality polymers, flavours and fragrances, pharmaceuticals, agrochemical actives and beyond.

The LGO platform will either produce materials capable of out-performing traditional counterparts or ‘drop-ins’, prized for their chirality and complex structures, which are manufactured more economically in fewer, safer steps.

For example, in 2022, a team at Merck (USA) won the Dunn Award for outstanding industrial implementation of novel green chemistry for employing the LGO platform to reduce the total synthesis of an established cancer drug from 11 steps to two steps as well as removing toxic solvents in favour of Cyrene.

Cyrene itself is a multi-purpose industrial solvent with applications as diverse as chemicals, pharmaceuticals, materials, electronics, inks, graphene, foods/flavours and emerging sectors such as textile recycling and batteries. Cyrene has a unique property set, including viscosity, surface tension and polarities. It can work to replace dipolar aprotic solvents that are under regulatory pressure for their toxicity, i.e. NMP, DMF, DCM.

Additionally, unlike other solvents, Cyrene forms a controllable, reversible equilibrium with water and can disperse carbon materials such as graphene with up to ten times the loading seen with NMP.

Forming the BBI JU ReSolute consortium

However, as we look to tomorrow, we need to not only build commercial chemical plants to produce safer, sustainable, bio-based molecules with which to transform the chemical industry into the net-zero industry society demands, but we also need to build their associated supply-chain ecosystems.

To this end, Circa has forged collaborations to create the 11-partner strong consortium that comprises the €11.6m ReSolute Bio-based Industries Joint Undertaking (BBI JU) project.

The ReSolute partners include Huntsman, Talga and Merck KGaA, who are developing Cyrene commercial applications for wire coatings, graphene coatings, graphene batteries, pharmaceuticals and membranes, respectively. The distributor, Will & Co., is a further partner working with Circa and the consortium to develop commercial applications and markets.

Additionally, AgroParisTech is scaling up an enzymatic route to Cyrene from LGO, which is metal-free to ensure the electronics and pharmaceutical applications have available material.

Rounding out the project partners working on valorising the plant output is Coal Products Ltd (CPL), which is carrying out R&D to validate the ReSolute plant’s biochar co-product for sale into the high-added-value carbon markets.

The ReSolute plant will be equipped to burn the biochar internally to meet the plant’s internal power needs and thus de-risk from utility pricing volatility; however, if higher added-value carbon products prove their economic worth, then the engineering design gives scope to optimise opportunity by selling the biochar as offtake.

To complete the ecosystem, ReSolute is fortunate to have Vitis Regulatory Ltd as the partner handling the required Cyrene REACH registration and the Green Chemistry Centre of Excellence at the University of York, which is developing quality assurance and purity grades for Circa’s novel products. The bioeconomy cluster Bioeconomy For Change (B4C) is handling communications and dissemination for the ReSolute BBI JU project, with exploitation activities being led by PNO Consultants.

Scaling up production of sustainable chemicals

The ReSolute biorefinery is located in the Grant-Est region of France. It will re-purpose a coal-fired power station to create a lower carbon economy that provides skilled jobs in clean technologies. Support from local, regional and national governments has been notable; culminating in a visit by the French State Minister of Industry to the ReSolute plant site (see image) and the awarding of a multi-million Euro Relance grant by the French Government to further support.

The ReSolute BBI JU project is a Flagship project. It is one of a few carefully selected commercialisation projects targeting the building of first-of-their-kind-in-Europe biorefineries on a commercial scale. Each has a high replicability potential for further, larger plants to be built across the continent leveraging regional feedstocks, supply chains, workforces and offtake markets. This vision aligns exactly with Circa’s goal of further scaling up, with the next 12,000-tonne scale plant already being planned.

The ReSolute plant has been designed as a test bed with the exact design of future larger plants to enable easier and swifter scale-up with modular engineering. Phillip Mengal, former Executive Director of the BBI JU and Circular Bio-based Europe Joint Undertaking (CBE JU), said: “ReSolute is the Green Deal in motion.”

Seizing the opportunity of sustainable chemicals

Perhaps, as you read this article, you are thinking ‘great but what comes next?’ Essentially, Circa and the ReSolute project need your active involvement to reach its long-term potential at a scale of tens of thousands of tonnes. Looking at the ReSolute project and beyond, after decades of outstanding R&D and millions in investment, science has delivered previously unimaginable solutions to our climate, biodiversity and resource challenges.

Industrial biotechnology and bio-based innovation means (for example) household waste can become organic-based chemicals, industrial waste gases act as fertiliser feedstocks and non-food cellulosic biomass can be converted into a novel, low-toxic industrial solvents, as Circa has proven.

Plus, digitalisation, Artificial Intelligence (AI) and the Internet of Things (IoT) are revolutionising manufacturing alongside 3D printing, electrification and renewables – i.e. the technical and engineering barriers to achieving a sustainable, safer chemicals industry using feedstocks that are renewable, bio-based and/or waste-derived are being stripped away.

However, the true value of these innovations will only be realised if they are nurtured beyond the pilot scale to achieve industrial scale-up and end-use. It is here where the challenge lies, given the investment needed and new markets/applications, with the policy to support them, that must be developed to compete with our petroleum-subsidised industry of today.

Can we afford to let groundbreaking innovations falter at scale-up while we turn to marvel at the newest shiny idea? We’d assert, given the challenges we face as a society a quarter of the way through the 21st century, the answer is ‘no’ regardless of the notable challenges associated with industrial scaling-up.

We could argue that R&D may be deemed the ‘easy’ part compared to the formidable task of engaging industrial stakeholders, fostering political will, securing financial support, redefining regulations and policies, embracing risk, altering end-user practices, managing legacy assets, shaping consumer perceptions, and, ultimately, constructing and operating commercial plants.

Nonetheless, a collective effort involving industry, governments, end-users, policymakers, innovators, and citizens globally is building the industrial-scale change we need in the chemicals we manufacture, use and dispose of. Circa is actively contributing to this transformative journey alongside the ReSolute consortium and BBI JU, and we invite you to step up and join forces with us in reshaping chemistry at a scale that will endure for good.

This project has received funding from the Bio Based Industries Joint Undertaking (JU) under grant agreement No 887674. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Bio-Based Industries Consortium.

Please note, this article will also appear in the seventeenth edition of our quarterly publication.