ELEMISSION’s ECORE LIBS drill core scanner provides detailed mineralogy and textural information rapidly.

Exploration, mining, and mineral processing account for a significant proportion of global GDP. Comprehensive and robust ore body analysis is information that is necessary for determining the viability and profitability of an ore deposit.

Characterisation of the mineralogy of a deposit is a reliable way to improve ore body knowledge through the validation and refinement of genetic models, which can then support exploration efforts and lead to new discoveries.

Traditional ore body analysis methods

Traditionally, a combination of techniques is used to understand the mineralogy of an ore deposit better. Thin sections for representative lithologies throughout a deposit are prepared and characterised by a geologist using a petrographic microscope. These interpretations generally need to be verified and further extended with secondary and even tertiary methods, such as scanning electron microscopy (SEM) or electron probe microanalysis (EPMA).

For more in-depth studies, trace element and isotopic analyses can be conducted using methods such as laser ablation inductively coupled plasma mass spectrometry (LA-ICP-MS) or secondary ion mass spectrometry (SIMS) to understand compositional zoning or timing of mineralisation better.

In more recent years, automated mineralogy solutions have been developed that utilise technologies such as SEM-EDS and X-ray Fluorescence (XRF) to generate mineralogical maps of thin sections or epoxy resin blocks.

While these techniques are useful for better understanding the mineralogy of an ore deposit, the scale of these analyses is quite small and limited by sampling. With a standard thin section size of 27 x 46 mm, a large quantity is required to produce a dataset that is representative of an entire deposit.

Additionally, smaller sample sizes increase the likelihood of biased sampling, which may induce sampling error, according to sampling theory. These traditional analyses are often quite costly and time-consuming (both in terms of analysis time and required sample preparation), further limiting how much of a deposit can be truly characterised. In an attempt to overcome some of these challenges, commercial drill core scanners using infrared hyperspectral imaging (IR-HSI) have become increasingly popular over the last decade to provide mineralogy on a larger scale.

These machines are capable of providing large amounts of textural and mineralogical information quickly and at a relatively low cost. While this significantly reduces scalability issues that are associated with traditional methods, there are many limitations to this technology that result in reduced data quality. Metal oxides, quartz, and sulphide minerals are not spectrally active with IR-HSI and, therefore, cannot be distinguished from each other.

In addition, the spot size of each analysis is ~1mm, resulting in mixed results in fine-grained lithologies. Infrared hyperspectral imaging (IR-HSI) is a molecular spectroscopy technique characterised by the presence of multiple spectral interferences, resulting in many minerals being indistinguishable from each other.

ECORE – An appropriate solution for large-scale mineralogy

ECORE (Fig. 1), manufactured by ELEMISSION Inc. (Montréal, QC, Canada), is a fully automated, high-speed, commercial laser-induced breakdown spectroscopy (LIBS) commercial drill core scanner that rapidly provides automated mineralogical and chemical assays while providing high-quality and accurate information.

ECORE is capable of providing SEM-EDS-level quality mineralogy directly on the drill core, with a spot size of 30 µm and a resolution (spacing between analysis points) that is fully adjustable by the user. Equipped with ELEMISSION’s proprietary and user-friendly LIBS CONTROL software and Smart Automated Mineralogy (SAM) algorithm, users have access to fast and accurate quantitative mineralogy within minutes (about five minutes per core box at standard resolution).

The unique use of LIBS technology allows for the detection of every naturally occurring element on the periodic table (from hydrogen to uranium). LIBS is an atomic emission spectroscopic technique characterised by ultra-thin emission lines (less than 100 picometers) that minimise spectral interferences, enabling precise and accurate characterisation of minerals and elemental composition in rock samples. The high selectivity of LIBS elemental spectra means that users can see individual elements within minerals and understand elemental associations.

The unique combination of microscale probing spots and high selectivity of the atomic emission spectra brings the data required for high-fidelity quantitative automated mineralogy. It also allows users to distinguish between minerals containing the same elements in varying amounts and to see compositional variations within the same mineral.

ECORE is able to provide rapid access to chemical and mineralogical information, along with high-resolution and detailed textural imagery. The following case studies demonstrate how ECORE’s unique features are used to provide information that would be otherwise inaccessible at a large scale for unlocking deposit potential and enhancing ore body analysis.

Case study one: Differentiating arsenic-bearing pyrite and arsenopyrite

For many gold deposit types, the presence of arsenic-bearing minerals is known to be associated with gold mineralisation. Properly constraining the deportment of arsenic within a deposit can, therefore, provide invaluable insight into understanding controls on gold mineralisation to facilitate decision-making and generate future drilling targets.

The orogenic gold deposit that is the focus of this case study has gold mineralisation that is almost exclusively refractory and is associated with disseminated sulphide mineralisation and related hydrothermal alteration. In general, gold particles are primarily trapped within fine-grained arsenopyrite or arsenic-rich pyrite crystals. Higher concentrations of arsenic are typically associated with higher gold concentrations.

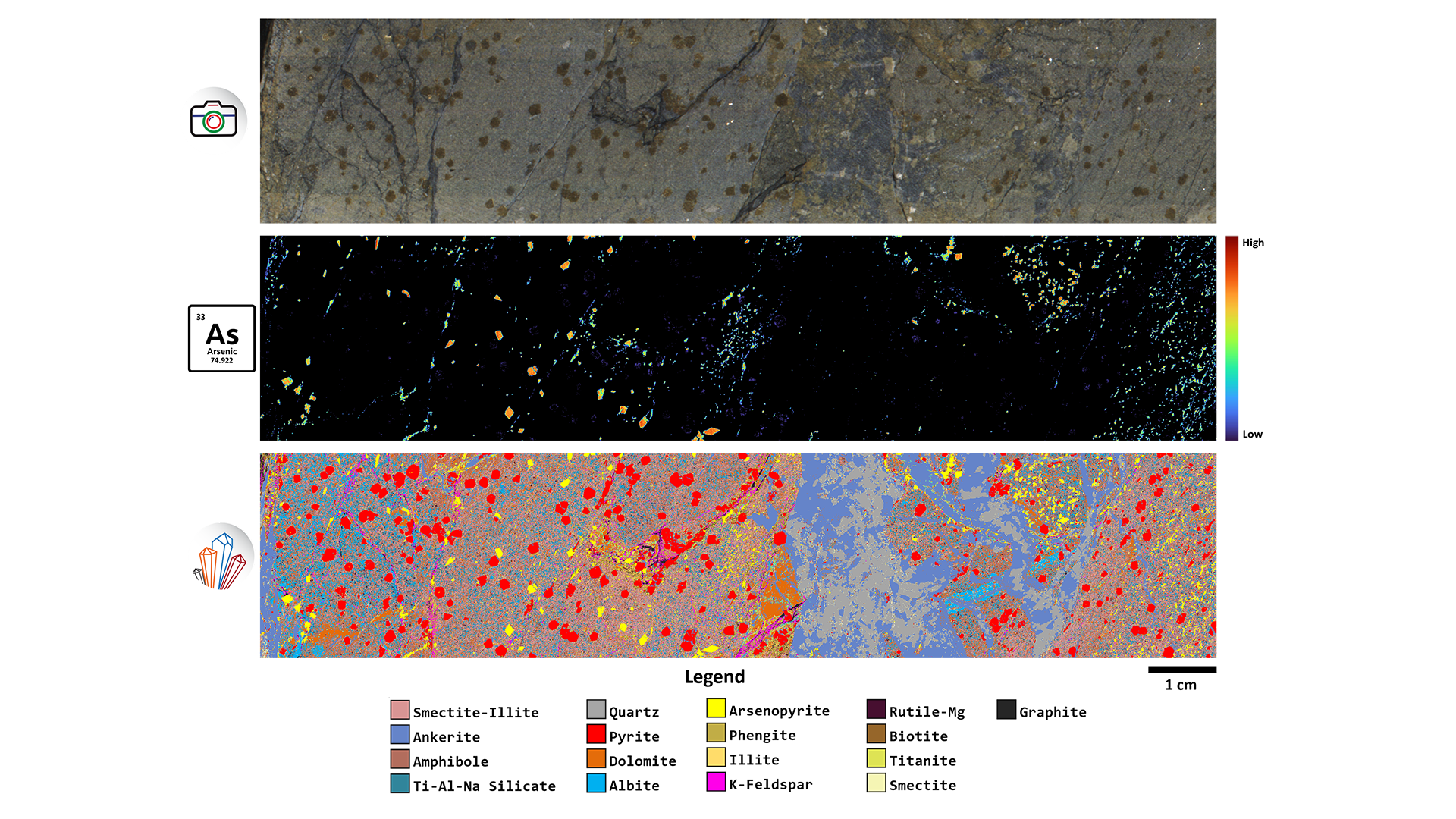

The selectivity and sensitivity of ECORE technology allow users to distinguish between arsenopyrite, As-bearing pyrite, and non-As-bearing pyrite. Using a combination of mineralogical and elemental mapping (Fig. 2), the distribution of As throughout the core can be observed, and subsequently, mineralogical, textural, and chemical affinities between As-bearing pyrite and non-As-bearing pyrite can be established.

ELEMISSION’s Smart Automated Mineralogy (SAM) software of a section of drill core from an orogenic gold

deposit. Arsenopyrite can be differentiated from As-bearing pyrite and non-As-bearing pyrite

The textural and chemical characteristics of these minerals can be used to better understand the implications concerning the mechanisms and timing of gold deposition. Access to detailed mineralogy promotes easy and accurate deposit characterisation and identification of alteration assemblages, allowing for informed decisions to be made for future exploration.

Case study two: Detailed mineralogical mapping used to reconstruct events associated with VMS mineralisation

Understanding the paragenesis (order in which minerals comprising a rock are formed) of a deposit is critical for establishing the context of different phases within a deposit. This comprehension allows mineralisation to be correlated with distinct fluid episodes and associated characteristic phase assemblages, which can then be used to develop strategies for geochemical exploration.

Paragenesis is usually determined by examination of polished thin sections or resin blocks using various techniques (e.g., SEM, EPMA, LA-ICP-MS). However, the representativeness of a single thin section/block decreases significantly with increasing deposit scale, where vein and dyke systems can be hundreds of meters or even kilometres long.

This, combined with the heterogenous phase distribution that is often observed to have happened during different fluid injections, adds to the challenge of sample representativeness.

ECORE has the ability to provide mineralogy results comparable to SEM-EDS across an entire core box within minutes, creating the opportunity to maximise sample representativeness. ECORE provides rapid access to automated mineralogical and textural information at the macroscale and can be applied to entire drill programmes.

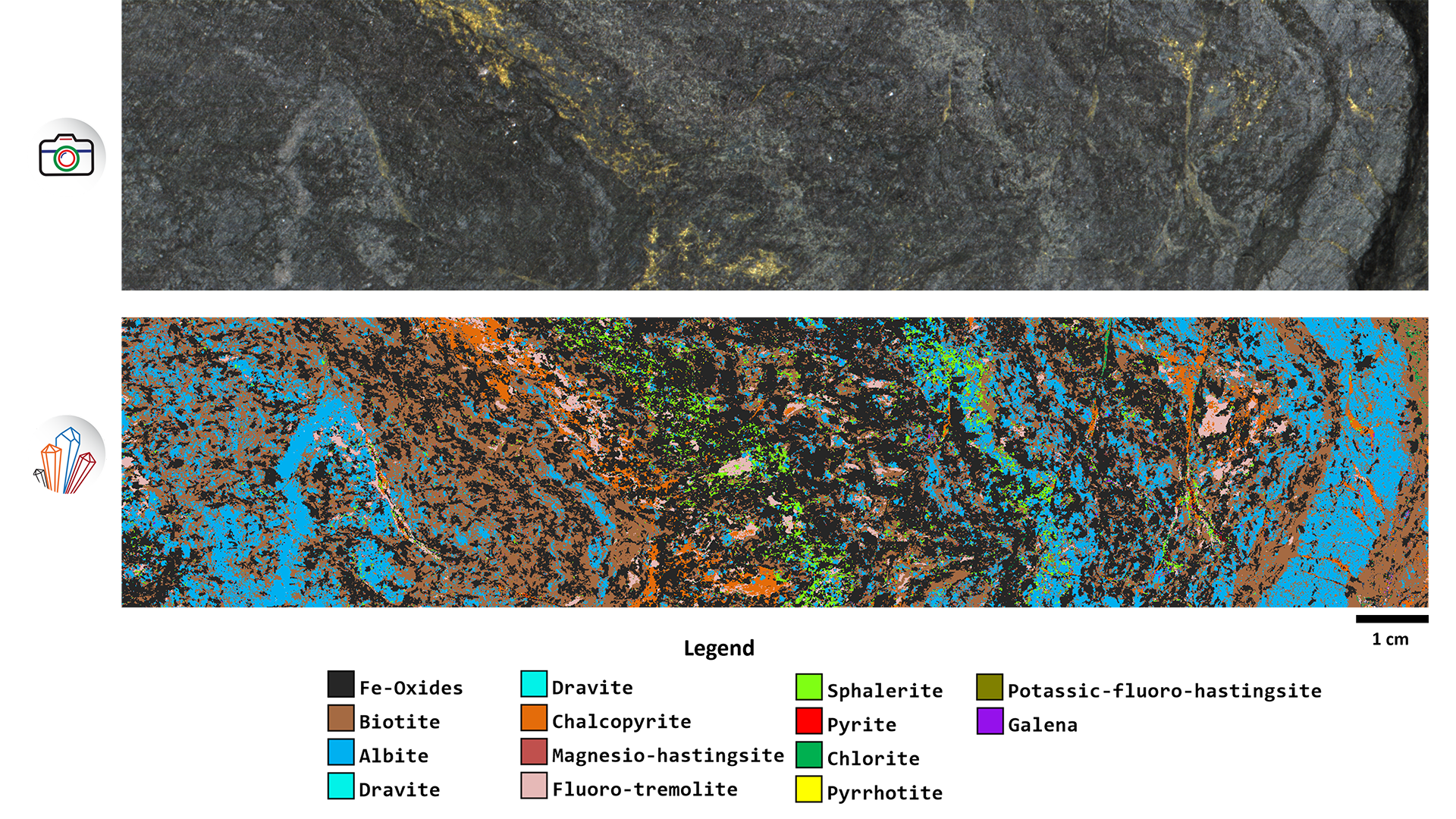

ECORE technology was used to characterise drill core (Fig. 3) and thin section off-cuts (Fig. 4) from a VMS deposit that has undergone strong deformation and metamorphism. The deposit contains two styles of mineralisation, mineralogically and texturally distinct, which are characteristic of VMS deposits. High-resolution automated mineralogical mapping performed by ECORE allowed for accurate visualisation and correlation of texture and phaser relationships, contributing to the overall paragenetic knowledge.

LIBS technology is able to detect and differentiate between different sulphide and metal oxide phases, eliminating the ambiguity that is common when using hyperspectral imaging. With ECORE, resolution can be adjusted down to 30µm at the touch of a button. This means that any area of interest can be re-scanned at an ultra-high resolution to highlight ultra-fine features that might otherwise be missed at a lower resolution.

Revolutionising ore body analysis

ECORE is a unique tool that greatly enhances ore body analysis by empowering geologists through detailed mineralogical and textural mapping. Users can gain a superior understanding of elemental distribution within a deposit, which has implications for pathfinder and indicator mineralogy while also maximising sample representativeness with the ability to scan entire core boxes in minutes.

Please note, this article will also appear in the 19th edition of our quarterly publication.