TAU Systems is transforming space electronics testing with its compact, cost-effective, ultrafast accelerators that provide radiation-testing-as-a-service, enhancing the resilience of critical space-bound technologies against cosmic radiation.

As humanity pushes further into the cosmos, the resilience of space-bound electronics becomes an ever-pressing challenge. Satellites, spacecraft, and defence systems operate in some of the most extreme environments imaginable, where high-energy cosmic radiation can disrupt or even permanently damage critical electronic components.

Ensuring the robustness of these systems has traditionally relied on limited and expensive radiation testing facilities. But a new era is emerging, one where advanced, compact accelerators provide radiation-testing-as-a-service, dramatically enhancing accessibility and effectiveness when testing space-bound electronics.

The need for advanced space electronics testing

In the unforgiving environment of space, electronic components face a phenomenon known as Single Event Effects (SEE). These occur when high-energy particles, such as protons or heavy ions, strike a semiconductor, generating currents or voltage spikes that can lead to temporary malfunctions or catastrophic failures.

As modern computing relies on increasingly small and powerful transistors, the vulnerability of space-bound electronics to SEE is growing. With current radiation-hardened electronics, AI, machine learning, and autonomous decision-making have yet to play a major role in space missions, as the chipsets required for these advanced technologies have yet to be developed and tested to withstand cosmic radiation.

Historically, SEE testing has relied on conventional ion accelerators, which are large, costly, scarce and geographically constrained. These limitations have created bottlenecks in radiation-hardening processes, making it difficult for satellite manufacturers, defence organisations, and space agencies to access the testing resources they need. Transformative technologies are needed to address this large and growing gap.

TAU Systems: Pioneering radiation-testing-as-a-service with compact accelerators

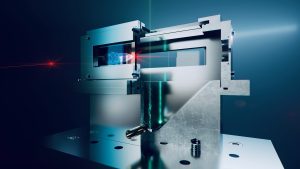

TAU Systems, the leader in ultrafast compact laser-plasma accelerators, aims to redefine how radiation testing is conducted. Leveraging its Laser Wakefield Accelerator (LWFA) technology, TAU Systems is developing a compact, cost-effective solution for SEE testing to replicate the radiation conditions found in space with unprecedented precision. Unlike traditional accelerators, TAU’s system is significantly smaller, housed in a space no larger than a shipping container, and is yet capable of generating high-energy electron beams that can effectively test space electronics.

TAU Systems is working to expand the availability of SEE testing to ensure that critical space-based technologies, from next-generation satellites to interplanetary exploration probes, are designed with maximum resilience. With its U.S.-based facility, TAU Labs, set to deliver up to 4,000 hours of beam time per unit annually, TAU Systems will significantly increase access to critical testing services, helping to eliminate the bottleneck that has long challenged the industry.

Unlocking the benefits of radiation-testing-as-a-service

Beyond accessibility, TAU’s compact accelerator technology will provide multiple advantages:

- Precision testing: TAU’s ultrafast electron beams emulate the high-energy cosmic radiation encountered in space, ensuring that SEE testing accurately reflects real-world conditions.

- Cost efficiency: The compact, energy-efficient design of the LWFA system significantly reduces the operational costs associated with traditional accelerator-based testing.

- Scalability: With multiple facilities generating thousands of hours of beam time per year, TAU Systems will accommodate the growing industry demand for radiation testing without the constraints of traditional testing centres.

- Multifunctional applications: Beyond SEE testing, TAU’s compact accelerators can support a range of cutting-edge applications, including medical imaging, semiconductor development, and cancer treatment research.

Strengthening space exploration and defence

The implications of TAU Systems’ innovation extend far beyond radiation testing. As the global space industry accelerates, driven by commercial ventures, governmental space programmes, and defence initiatives, the need for robust electronics is more critical than ever. The TAU Labs model supports security by ensuring that defence satellites and strategic space assets are resilient against radiation-induced failures. Likewise, as human spaceflight ventures beyond low-Earth orbit to destinations like the Moon, Mars, and beyond, the ability to test and harden electronics against cosmic radiation is essential.

Moreover, the scalability of TAU’s technology will enable the rapid iteration and deployment of new satellite architectures, empowering private space companies to innovate without the constraints of legacy testing infrastructures. This shift not only strengthens the space industry’s technological backbone but also accelerates the deployment of next-generation space capabilities.

The future of radiation testing: A call to action

As the space industry embraces increasingly complex and intelligent technologies, the demand for reliable, cost-effective SEE testing will only intensify. TAU Systems’ compact accelerator-based radiation-testing-as-a-service solution represents a transformative leap forward, eliminating traditional barriers to radiation testing while enhancing the reliability of space-bound electronics.

By working to make high-energy SEE testing more accessible, TAU is helping to de-risk space missions, improve satellite longevity, and support the next wave of space innovation. The ability to rapidly test and validate electronics against space radiation will be a cornerstone of future exploration efforts, ensuring that technological ambitions are matched by resilience in the face of cosmic adversity.

For satellite manufacturers, space agencies, and defence contractors seeking a competitive edge in space electronics, the time to act is now. Investing in advanced SEE testing solutions like TAU Systems’ radiation-testing-as-a-service model will be key to safeguarding the future of space exploration, national security, and scientific discovery.

TAU Systems is not just advancing radiation testing; it is shaping the future of space exploration itself. As we venture further into the cosmos, the resilience of our electronics will define the success of our missions. With ultrafast compact accelerators powering the next generation of SEE testing, space-bound technologies will be more robust, reliable, and ready for the extreme realities of the final frontier.

Please note, this article will also appear in the 22nd edition of our quarterly publication.