LED UV-C Systems explores the use of efficient and sustainable UV-C LED water disinfection in a diverse range of industries to ensure pathogen-free water and compliance with IPC standards.

Water disinfection plays a critical role in infection prevention and control (IPC) across multiple industries. From healthcare to hospitality, ensuring clean, pathogen-free water is essential to maintaining safety and regulatory compliance. While conventional methods, such as chemical disinfection and mercury-based UV lamps, have historically formed the backbone of many water treatment protocols, the emergence of UV-C LED technology is rapidly changing how we approach water treatment.

UV-C LED solutions offer a sustainable, energy-efficient, and dependable approach to safeguarding water supplies, aligning with global environmental directives and evolving IPC standards. Unlike traditional mercury-based lamps, which often come with hazardous waste disposal challenges, UV-C LED systems contain no mercury and produce fewer environmental by-products. They also provide enhanced flexibility and targeted disinfection capabilities, which are increasingly vital for industrial, commercial, and municipal applications. As a result, UV LED water treatment is fast becoming an attractive option for organisations looking to balance robust water safety measures with sustainability objectives.

This article explores how UV LED water disinfection transforms pathogen control by harnessing UV light in water treatment. We also examine the role of UV light for water purification across various industries and demonstrate how the shift to point-of-use UV water treatment is strengthening localised water safety strategies. Whether in healthcare facilities, food processing plants, or large municipal systems, ultraviolet light in water treatment is reshaping best practices and driving innovation.

Understanding UV-C LED technology

A leap forward

UV-C LED systems represent a significant evolution in UV LED water treatment technology. Unlike mercury vapour lamps, which rely on the excitation of mercury atoms to generate UV light, UV-C LEDs produce UV photons via the electroluminescence of a semiconductor crystal. This core distinction in construction confers key benefits in terms of durability, efficiency, and operational flexibility – attributes increasingly important in modern UV LED water disinfection solutions.

- Durability: UV-C LEDs are solid-state devices, making them inherently resistant to shocks and vibrations. This is especially valuable in challenging environments such as industrial or municipal settings, where reliability is paramount. Furthermore, the solid-state nature of LEDs means they are less susceptible to degradation compared to glass-based mercury lamps, reducing maintenance requirements over their operational life. For industries like food processing that need robust, long-lasting solutions, UV-C LEDs deliver consistent performance with minimal downtime.

- Instantaneous power cycling: One significant advantage of UV-C LEDs over traditional mercury lamps is their ability to ramp from 0-100% power in milliseconds. Mercury lamps, by contrast, often require extended ‘warm-up’ times to reach the temperature required for effective pathogen inactivation. This quick switching on and off enables UV light in water treatment systems to deliver disinfection on demand, making them particularly beneficial for intermittent-flow scenarios. In point-of-use UV water treatment setups, this energy-saving feature can substantially cut both power consumption and operational costs.

- Energy efficiency: In intermittent-use applications, UV-C LEDs dramatically out-perform mercury lamps on energy consumption. Mercury-based systems typically must remain on continuously to be ready at a moment’s notice, resulting in high standby power usage. By cutting standby energy requirements, UV-C LEDs reduce both operational costs and carbon footprints. Hospitals, industrial facilities, and even universities striving for sustainability find that UV LED water disinfection aligns neatly with their environmental goals.

- Minimal thermal transfer: An often-overlooked advantage of UV-C LEDs is their inherently lower operating temperatures. Unlike mercury lamps, which can reach high ‘skin’ temperatures on their quartz sleeves and often require purging water to drain in order to cool the reaction chamber, UV-C LEDs do not transfer significant heat onto the quartz or into the water. This cooler operational profile greatly minimises the risk of mineral deposits and other fouling on the quartz components, reducing maintenance intervals and ensuring more consistent disinfection performance. As a result, industries can realise both efficiency gains and cost savings by avoiding the frequent cleaning or replacement of fouled sleeves.

- Compact design: The small footprint of UV-C LED modules makes them ideally suited to integration into point-of-use UV water treatment devices, portable disinfection systems, and custom-built solutions for niche industries. Their modular design also allows scalability: building a system that handles larger flow rates can be as simple as adding more LED modules without the extensive reconfiguration often required by mercury-based systems.

The science behind UV disinfection

UV-C’s germicidal power

Ultraviolet light in water treatment is effective because UV photons disrupt the DNA or RNA of pathogens, inhibiting replication. Specifically, the germicidal range of 200-280 nm (UV-C) is highly potent against a broad spectrum of microorganisms, including bacteria, viruses, and protozoa. Key benefits include:

- Mechanism: The energy in UV photons damages microbial cells by breaking molecular bonds in their genetic material – a process known as photodimerization. As a result, microorganisms lose the ability to reproduce, effectively rendering them harmless. This mechanism underpins UV light for water purification, ensuring safe, clean water for a variety of end uses.

- Log reductions: UV disinfection can achieve up to a 99.999% (5-log) reduction in microbial load, depending on dose and exposure time. Research shows that UV doses of 16-40 mJ/cm² are typically sufficient to inactivate a wide range of pathogens, including E-coli, Pseudomonas aeruginosa, and Cryptosporidium parvum (Haji Malayeri et al., 2016). These impressive inactivation rates mean UV LED water treatment can meet some of the most rigorous water safety regulations, making it suitable for healthcare, pharmaceutical industry, hospitality, food processing, and beyond.

- Validation: A growing body of evidence supports the use of UV LED water disinfection in both potable and non-potable water systems. Studies regularly demonstrate that, compared to conventional treatments, UV-C LED technology can achieve robust pathogen inactivation without any chemical additives or supplementary processes. This method’s ability to disinfect without altering taste or introducing residual chemicals is a major advantage in food and beverage applications.

- Dosing and calibration: Because UV-C LEDs can be finely tuned for power output, it is possible to optimise dosing based on flow rate, water quality, and target microorganisms. This fine-tuning prevents energy overshoot – wasting power when it’s not required – and ensures adequate pathogen inactivation. In this way, UV light in water treatment becomes both practical and cost-effective.

Pathogens of concern in key markets

Versatile disinfection for multiple sectors

Thanks to its broad-spectrum efficacy, UV LED water treatment addresses the challenges posed by various waterborne pathogens across a wide range of industries:

- Healthcare: Hospitals and clinics face the persistent threat of Pseudomonas aeruginosa and non-tuberculous mycobacteria (NTMs), especially in shower water systems used by immunocompromised patients. UV light in water treatment can significantly reduce the risk of these opportunistic pathogens without over-reliance on chemical disinfectants. Legionella pneumophila, a critical pathogen in hospital hot water supplies, is also well-controlled by consistent UV dosing.

- Built environment: In commercial and residential buildings, effective water treatment is necessary for potable water systems, decorative water features, and cooling tower makeup water. Traditionally, mercury lamp-based units were challenging to service, especially in cramped plant rooms or older buildings with tight maintenance spaces. However, UV LED water treatment solutions – often featuring side-mounted lamp packs – take up far less space. Moreover, point-of-use UV water treatment systems can be installed directly at underused outlets, showers, or faucets, reducing pathogen risks associated with stagnant water and ensuring compliance with IPC regulations.

- Food and beverage: When it comes to ensuring the safety of rinse water and process water, key pathogens such as E. coli, Salmonella, and Cryptosporidium must be eliminated. UV light for water purification is incredibly precise, delivering reliable disinfection that helps uphold stringent standards in the food and beverage sector. Additionally, by reducing the microbial load in wash waters, UV-C technology can extend the shelf life of perishable items – an invaluable advantage for fresh produce growers and beverage manufacturers who need to reduce spoilage risks.

- Industrial applications: Industries dealing with process water, including manufacturers and cooling towers, benefit substantially from UV LED water disinfection. UV-C LEDs effectively target biofilm-forming organisms that can compromise equipment integrity or hamper productivity. In scenarios where water flow is intermittent, such as in certain cooling tower makeup water supplies, the rapid on/off capabilities of UV-C LEDs help reduce energy waste and operational costs.

- Public spaces: Public fountains, recreational water facilities, and even decorative features in hospitality settings can all harness ultraviolet light in water treatment for safe and chemical-free disinfection. This removes the need for potentially harmful chemicals, making the water safer for public interaction and reducing overall environmental impact.

Tailored product offerings

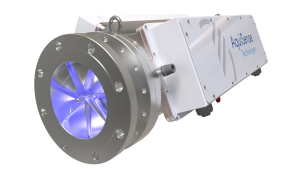

AquiSense’s PearlAqua product line exemplifies the versatility of UV LED water treatment. At the industrial and commercial scale, the PearlAqua Kilo is engineered for high-capacity disinfection under demanding conditions. For municipal-level applications, the PearlAqua Tera delivers reliable microbial control for larger populations.

Meanwhile, at smaller or decentralised scales, the Deca 30C excels in high-flow point of use UV water treatment scenarios, ensuring robust disinfection at individual outlets. The Deca 24C4, on the other hand, operates effectively as a point-of-entry system (POE) for smaller-scale industrial or commercial set-ups. Finally, the PearlAqua Micro is renowned for its compact form factor, making it ideal for both POU installations and OEM integrations that require flexible design options.

These systems have been rigorously studied, including at Dalhousie University in East Passage, Nova Scotia. Research there highlighted the PearlAqua Tera’s potential in wastewater treatment, demonstrating not only its ability to achieve pathogen-free effluent but also to realise noticeable energy savings compared to mercury lamp-based systems. The success of these trials underlines the growing acceptance of UV-C LED technologies for robust water treatment worldwide. More details can be found in Dalhousie’s published research findings.

Sustainable and effective IPC with UV-C LEDs

Driving down environmental impact

One of the most compelling arguments for UV LED water treatment is its alignment with global sustainability initiatives, such as the Minamata Convention, which seeks to reduce – and ultimately eliminate – mercury usage in various technologies. Similarly, the European Union’s regulations banning or limiting mercury use underscore the need for viable alternatives.

- Sustainability: As UV LED water disinfection relies on semiconductor technology rather than mercury, it not only eliminates the release of hazardous substances into the environment but also drastically simplifies end-of-life disposal. Moreover, zero harmful by-products are produced during operation, making UV light for water purification via LEDs a greener choice overall.

- Energy efficiency: UV-C LEDs can be idle on extremely low power, switching to full intensity only when water flow or disinfection demand requires it. This feature is critical in intermittent-use scenarios, where continuous lamp operation would be a major energy burden. UV-C LED technology has evolved to deliver high-intensity output during active flow periods while minimising energy draw during downtime – an improvement over even high-end mercury-based units.

- Regulatory compliance: As the EU and other global bodies move closer to stricter rules on mercury-based technologies and chemical disinfectants, adopting UV light in water treatment through LED solutions helps companies stay one step ahead. Employing a mercury-free approach also supports broader environmental objectives, future-proofing facilities and infrastructures against impending regulatory shifts.

The future of UV-C LED water treatment

Continued innovation and opportunities

UV-C LED technology, guided by performance principles like Haitz’s Law, continues to become more efficient and cost-effective. Haitz’s Law predicts an exponential improvement in LED output and an inverse decline in cost – trends we are already witnessing in the area of UV LED water disinfection.

- Technological advancements: Recent breakthroughs in semiconductor manufacturing are steadily increasing the wall-plug efficiency of UV-C LEDs. Higher efficiencies mean that more UV light can be produced per unit of electrical energy consumed, opening the door to both higher flow rate applications and further energy savings.

- Scalability: Because UV-C LEDs can be modularly incorporated into larger systems, they support configurations ranging from small-scale point-of-use UV water treatment to large municipal water plants. This scalability brings an unprecedented level of versatility to UV light for water purification, allowing system designers to customise solutions to specific pathogen challenges and flow rates.

- Emerging applications: Innovations such as wavelength customisation are emerging as a crucial differentiator for ultraviolet light in water treatment. By fine-tuning the LED’s emission peak, it’s possible to target specific pathogens or optimise disinfection in complex water matrices. Additionally, with no hazardous materials to worry about and minimal warm-up times, UV-C LEDs are uniquely suited to ‘mobile’ or remote water treatment systems for disaster relief and field hospitals.

- Sustainability and compliance: As international regulations continue to phase out mercury-based systems, more industries will adopt UV LED water treatment to remain compliant. This shift not only addresses regulatory mandates but also supports long-term sustainability goals, reducing environmental risks linked to mercury disposal. Ultimately, as UV-C LED technology matures, more facilities will rely on UV light in water treatment strategies that are cleaner, safer, and better aligned with global ecological ambitions.

- Closing thoughts: By integrating UV LED water disinfection systems into water safety programmes, organisations can enhance both public health and environmental stewardship. Reduced chemical usage, lower energy consumption, and improved flexibility are just a few of the benefits UV-C LEDs bring to modern water treatment. As developments in semiconductor technology continue, the potential applications of UV light for water purification will expand further, paving the way for a future where waterborne pathogens can be neutralised with minimal ecological impact.

Final takeaways

The field of UV LED water treatment is rapidly evolving, offering robust, sustainable, and cost-effective solutions that go beyond what was once possible with legacy mercury-based systems. From point-of-use UV water treatment in hospitals and commercial buildings to large-scale industrial or municipal setups, UV LED water disinfection is transforming water safety protocols. By harnessing UV light in water treatment in a way that is reliable, mercury-free, and adaptable to real-time demand, this technology stands as a pillar of both present and future water purification strategies. Whether one is concerned with compliance, sustainability, or simple operational efficiency, ultraviolet light in water treatment through LEDs undoubtedly presents a compelling avenue for progress in IPC and beyond.

Through continuing research and development, we can anticipate even greater leaps in efficacy and affordability, ensuring that UV light for water purification remains an essential, innovative tool in the global effort to secure safe, pathogen-free water for all.

Please note, this article will also appear in the 21st edition of our quarterly publication.