A research team from The Fraunhofer Institute for Machine Tools and Forming Technology IWU has adopted the stiffness in robots to combine it with the needed strength and safety to improve robotic assistance devices.

A team of researchers from The Fraunhofer Institute have presented a robotic assistance device— a robotic arm— at the Hannover Messe Preview on 16 March 2022, and will present it again at the Hannover Messe from 30 May to 2 June 2022. This robot arm could facilitate the support of vulnerable people in their direct surroundings.

How has human interaction been considered in the production of these devices?

The intention that researchers at Fraunhofer IWU have is to drive robotics forward in areas involving close proximity to humans.

“Robots for use in close proximity to humans generate very different requirements from those used in industry, where workers can be trained in a specific way,” explained Linda Weisheit, Topic manager for the field ‘Robotics for Humans’ at Fraunhofer IWU. “If robots are going to be used in everyday life, first of all they need to be safe and second of all, they must have an appropriate appearance that increases acceptance.”

Thus, while humanoid robots are generally desirable in Japan, Europeans tend to find similarities to humans disconcerting. The researchers are therefore keeping a steady eye on the design side.

Soft robotics provides a good basis when it comes to safety. This is because it makes use of soft materials that cannot cause injuries. However, these robots are not able to perform as many tasks – for example, even a full cup of coffee would be too heavy for a soft robot arm to hold.

“We are therefore working on developing new structures with switchable stiffness – meaning they can switch between stiff and soft,” Weisheit said.

How will this ‘switchable stiffness’ be applied to robotic assistance devices?

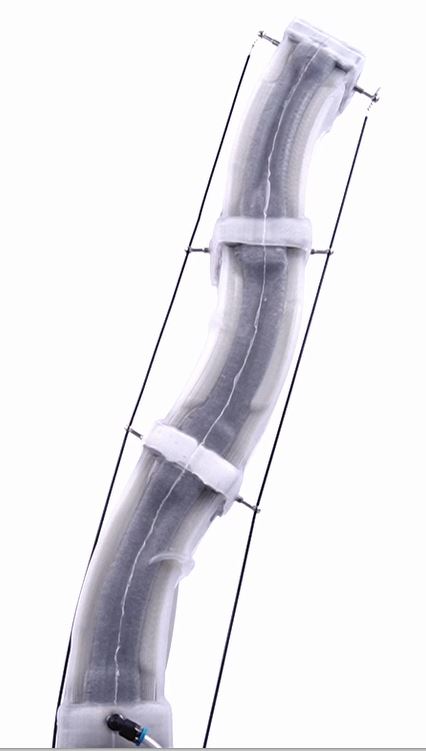

The principle behind this switchable stiffness is similar to that used in coffee packaging: When vacuum-packed, it is hard and solid, but if air gets in, then it becomes soft. In order to increase structural stiffness further, particularly under tensile strain, the team of researchers combined it with films placed on top of each other.

The result of this combination is a system that can withstand tensile strain as well as be resistant to compression. Utilising these kinds of structural components with switchable stiffness therefore makes it possible to design new movement concepts and new safety systems.

What this could mean for day-to-day life is best explained by employing an example such as a filled cup of coffee. If the robot needs to pick it up, it makes its soft arm a little stiffer so that it can apply the necessary force. In its solid state, it is 300 times stiffer than when it is soft; in other words, it has a switch factor of 300.

However, if a collision is imminent – for example, if a human gets too close – the mechanical assistant will not simply switch back to its soft state. That would cause the robotic assistance device to drop the cup onto the floor, leaving a pool of scalding hot coffee that might pose a risk to a small child. Instead, it is designed to execute an evasive movement. In other words: like a human, it gets out of the way of the obstacle while still holding the cup.

What does this mean for future applications?

Scientists have already taken the first step towards the overall robotic system and have provided an initial idea as to what the overall system could look like. Furthermore, relevant structural components have been developed, combined with sensors, and actuators as well as gesture control, and produced a tendon-driven robot arm that consists of three switchable segments and executes planar movements via gesture control.

“We want to start a dialog with users early on and find out what their specific needs are,” Weisheit concluded. This will allow the researchers to continue their developments regarding robotic assistance devices, in line with user needs.

To keep up to date with our content, subscribe for updates on our digital publication and newsletter.