Cayetano Hoyos Matías, Project Engineer at the SOERMAR Foundation and Technological Center, details how the SEABAT project is helping to electrify the maritime sector.

The International Maritime Organization (IMO) targets 50% lower annual greenhouse gas (GHG) emissions from maritime transport by 2050 compared to 2008 and even pursues efforts towards phasing them out entirely.

Electrification (retrofitted or newbuilds) is one of the solutions to reach this target, and the market for electrified ships is large. The SEABAT project, funded by the European Commission, opens the door for the use of energy storage systems (ESS) as a possible solution for reducing the environmental footprint of the maritime sector.

Challenges of electrifying the waterborne transport sector

Achieving these environmental objectives will not be an easy task, with the main issue being the type of battery systems used within the waterborne transport sector. Batteries are oversized by a factor of two to as much as ten to guarantee a specified capacity over a battery lifetime of approximately ten years. The oversizing brings high costs, which are an important barrier to increasing the market share of electrified ships. The challenge is to reduce the cost of large waterborne transport battery systems substantially.

SEABAT: A hybrid concept

That is why the overall objective of the SEABAT project is to develop a fully-electric maritime hybrid concept based on combining modular high-energy batteries and high-power batteries, novel converter concepts, and production technology solutions derived from the automotive sector.

Hybridisation allows the system to obtain high-power and high-energy capabilities while using the best properties of both energy storage devices. In hybrid configurations, the high-power part supports the high-energy battery or vice versa, depending on the requirements. High-energy devices will typically provide long-term power needs, whereas high-power devices will cater with short duration but higher-power needs. Therefore, the need for oversizing can be reduced and system lifetime can be extended. The load distribution between both storage devices is determined by the operating strategy of the energy storage system.

The advantages of hybridisation include:

- Up to 20% less weight;

- Up to 24% volume reduction potential; and

- Up to 24% cost-saving potential for the investment.

Additionally, studies on city buses have shown that hybridisation can increase the lifetime of the battery system by 16%.

For this reason, at SEABAT, four hybrid solutions have been studied and analysed to achieve the proposed objectives and promote the electrification of the naval sector, which are presented below.

Topology 1

Topology 1 is a hybrid basic solution with a high-power battery and a single DC/DC converter added to the circuit. The DC/DC converter unit is located between the high-energy battery and the high-power battery and enables bidirectional current flow, which is required for regenerative braking and recharging.

Topology 2

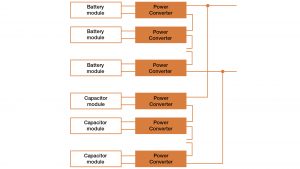

Topology 2 is SEABAT’s multi-level energy storage topology with a parallel-series interconnection to increase storable energy, capacity, ampacity, and/or achieve a higher output voltage. By design, it integrates the battery and power converter into one logical unit. In the most daring implementation, the converter can be integrated in the battery module, resulting in a module with built-in voltage control capabilities.

In that scenario, each module in the string can deliver an output voltage that is set by the energy management system to achieve the required, combined, DC bus voltage.

Topology 3

Topology 3 cells are switched on the individual level. A battery string is as strong as its weakest cell. Therefore, the total strength of a battery system can be improved by putting less stress on, or completely bypassing, weaker cells. In addition to making the total system more robust, it maximises control over the entire battery system. Because cells can be managed at the individual level, a hybrid system can easily be created by mixing high-energy and high-power cells at will.

Depending on the design, cells can be grouped into modules, which can be directly connected to form the battery system. For this part of the SEABAT project, a high-level DC/DC converter is not needed, as the individual cells can be actively (dis)engaged.

Topology 4

Topology 4 partial power processing configurations, such as partial power converters (PPC), are promising to make mixed power systems considerably more efficient and less expensive. PPCs have been proposed for a broad variety of unidirectional power flow applications. These converters are usually placed in series with an energy storage bank. In partial power converters, only a portion of the total power is processed, so both the converter cooling system and the total power losses are reduced. They are suitable for DC/DC applications where the voltage difference between the input and output terminals is not very high. For example, if the static voltage gain (VLOAD/VSOURCE) is double, half the power is processed. PPC architectures do not process the total power but do control the total power flow between two elements.

Once all the typologies were analysed and studied, the second typology was selected as the best option, as it presents significant advantages in cost, volume, weight, and energy losses than the rest of the topologies.

Additionally, recent innovations made in the field of batteries, mainly related on the specific energy and power densities, will facilitate the future electrification of the waterborne transport sector. From a chemical and technological point of view, nickel manganese cobalt oxide (NMC) is widely the most common, due to the high performances in terms of energy and power density and relative low costs. However, recent studies have shown the feasibility of using other types of battery systems within the waterborne transport sector, like lithium iron phosphate (LFP) and lithium titanate (LTO), which provide different performances and costs with reference to the NMC.

There has been significant advancements in the development of innovative battery system technologies, such as the SEABAT project, and in the use of different types of batteries within the waterborne transport sector. This has led to a significant increase in the construction of pure electric vessels, where medium-sized vessels with a short autonomy can be fully powered by the on-board battery system.

Likewise, ‘plug-in hybrid’ applications have a significant share of the total market and, in the near future, will partially replace the traditional hybrid configurations, also thanks to the systematic electrification of ports and docks, which would allow the batteries to be charged during stops in port, significantly reducing the polluting emissions of vessels.

Please note, this article will also appear in the fourteenth edition of our quarterly publication.